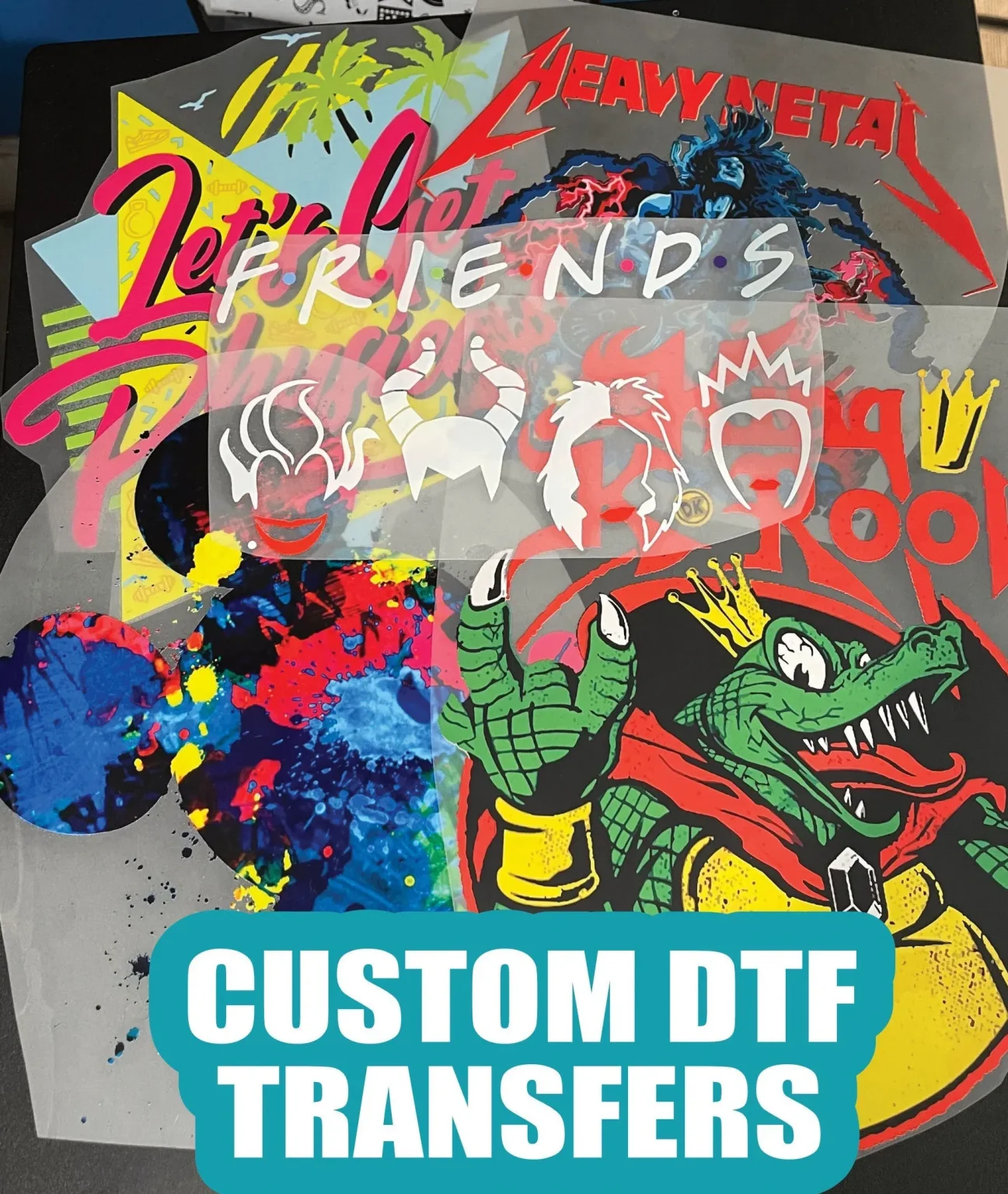

DTF transfers, or Direct-to-Film transfers, are reshaping the custom apparel landscape, offering an innovative solution for vibrant and durable fabric prints. This printing method stands out due to its unique ability to transfer intricate designs onto a wide array of materials, from cotton to blends with ease. In our comprehensive DTF printing guide, we delve into the numerous advantages of this approach, including its cost-effectiveness for smaller batches and its user-friendly setup, making it particularly appealing for beginners. For anyone venturing into the world of custom apparel printing, understanding the fundamentals of DTF printing is crucial for achieving high-quality results. Join us as we explore how this technique can elevate your creative projects to new heights.

Direct-to-Film printing, often referred to as DTF printing, is gaining traction in the textile industry as an effective method for transferring stunning designs onto fabric. This approach utilizes a specialized film that captures detailed graphics and allows for effortless application to various material types. With its rising popularity, many are turning to DTF transfers for their custom apparel needs, drawn by the flexibility and quality that this print method provides. For those new to the concept, DTF printing offers an accessible way to dive into the realm of fabric decoration, empowering creatives to produce eye-catching designs without the complex setup required by traditional methods. As we navigate this vibrant technique, it’s essential to recognize the transformative potential DTF can bring to both hobbyists and businesses alike.

Understanding DTF Transfers: An Introductory Look

Direct-to-Film (DTF) transfers are an innovative printing technique that is transforming the way designs are applied to fabrics. At its core, DTF printing involves printing designs onto a special transfer film, which can then be heat pressed onto the desired fabric. This method allows for an extraordinary range of applications, as it can be used on various materials, including cotton, polyester, and blends. Unlike traditional printing methods, DTF provides vibrant and high-quality prints that have a longer lifespan, resisting fading through countless washes.

For beginners, the DTF printing process can seem daunting at first, but it is remarkably user-friendly. The simplicity of the required equipment and materials makes it accessible even for those just starting out in the world of custom apparel. By grasping the basics of DTF transfers, you’ll discover how this versatile technique opens doors to creativity and customization at an affordable price.

The Many Advantages of DTF Printing

DTF printing comes with numerous advantages that make it a preferred choice for many. First and foremost, its ability to produce high-quality prints cannot be overstated. DTF transfers deliver vivid colors and intricate details, enabling designers to create stunning visuals that stand out. Unlike screen printing, where designs may lose their integrity over time, DTF prints remain strikingly durable and vibrant even after multiple wash cycles.

Additionally, DTF printing’s flexibility sets it apart from conventional methods. The adaptability to different fabric types, whether it’s t-shirts, hoodies, or accessories, means that artists and businesses can experiment freely. This versatility is particularly beneficial for small businesses, as DTF allows for customization without the hefty costs usually associated with bulk printing. Thus, it makes DTF printing an appealing option for those looking to engage in custom apparel printing.

Frequently Asked Questions

What are DTF transfers in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve a unique printing technique where designs are printed onto a special film. This film is then applied to fabric using heat and pressure, enabling vibrant and durable prints on various materials like cotton and polyester.

What are the main advantages of DTF printing for beginners?

The advantages of DTF printing for beginners include high-quality prints with exceptional vibrancy, flexibility to print on multiple fabric types, and cost-effectiveness for small batches. Additionally, DTF printing has a user-friendly process, making it accessible even for those new to custom apparel printing.

What equipment do I need for beginner DTF printing?

To start DTF printing, you’ll need a specialized DTF printer, transfer film for holding designs, adhesive powder for bonding prints, and a heat press to apply heat and pressure. Starter kits are often available to simplify the acquisition of these essential tools.

How does the DTF printing process work?

The DTF printing process includes four key steps: 1) printing the design onto the DTF film, 2) applying adhesive powder to the printed design, 3) using a heat press to transfer the design onto fabric, and 4) peeling away the film to reveal the final product.

How can I learn more about DTF printing techniques?

To enhance your knowledge of DTF printing techniques, explore online resources. Platforms like YouTube offer helpful tutorials, while blogs frequently provide tips and insights from experienced DTF printers. Engaging with community forums can also be beneficial.

What trends should I be aware of in the DTF printing market?

DTF printing is increasingly popular due to demand for customized printing solutions in fashion and promotional industries.Continuous technological advancements are enhancing DTF printing quality and efficiency, making it an attractive option for both startups and established businesses in the custom apparel market.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF printing involves printing designs onto a special film which is then transferred to fabric using heat, allowing for prints on various materials. |

| Advantages of DTF Transfers | 1. High-Quality Prints: Exceptional vibrancy and detail. 2. Flexibility with Fabric Types: Usable on various fabrics. 3. Cost-Effective for Smaller Batches: Lowers production costs. 4. User-Friendly Process: Minimal equipment needed. |

| Equipment and Materials Needed | 1. DTF Printer 2. Transfer Film 3. Adhesive Powder 4. Heat Press |

| Step-by-Step Process | 1. Print design onto DTF film. 2. Apply adhesive powder evenly on printed design. 3. Press the film using a heat press. 4. Peel the film to reveal the transferred design. |

| Learning Resources | Online platforms like YouTube, specialized blogs, and tutorial sites offer valuable insights and guidance for beginners in DTF printing. |

| Market Trends | Growing demand for customized printing solutions and technological advancements are driving the rise of DTF printing in various industries. |

| Challenges in DTF Printing | 1. Curing Temperatures: Must be accurate for best results. 2. Learning Curve: Beginners may face difficulty mastering the process. |

Summary

DTF transfers are transforming the custom printing landscape by offering beginners an innovative and accessible method of creating stunning, high-quality prints. This exceptional technique not only provides vibrant and durable designs but also caters to a variety of fabrics and production needs. As enthusiasts venture into the world of DTF transfers, they can easily equip themselves with the necessary tools and knowledge to produce professional-grade apparel. Embracing DTF transfers not only enhances creativity but also positions users competitively in the growing custom printing market.