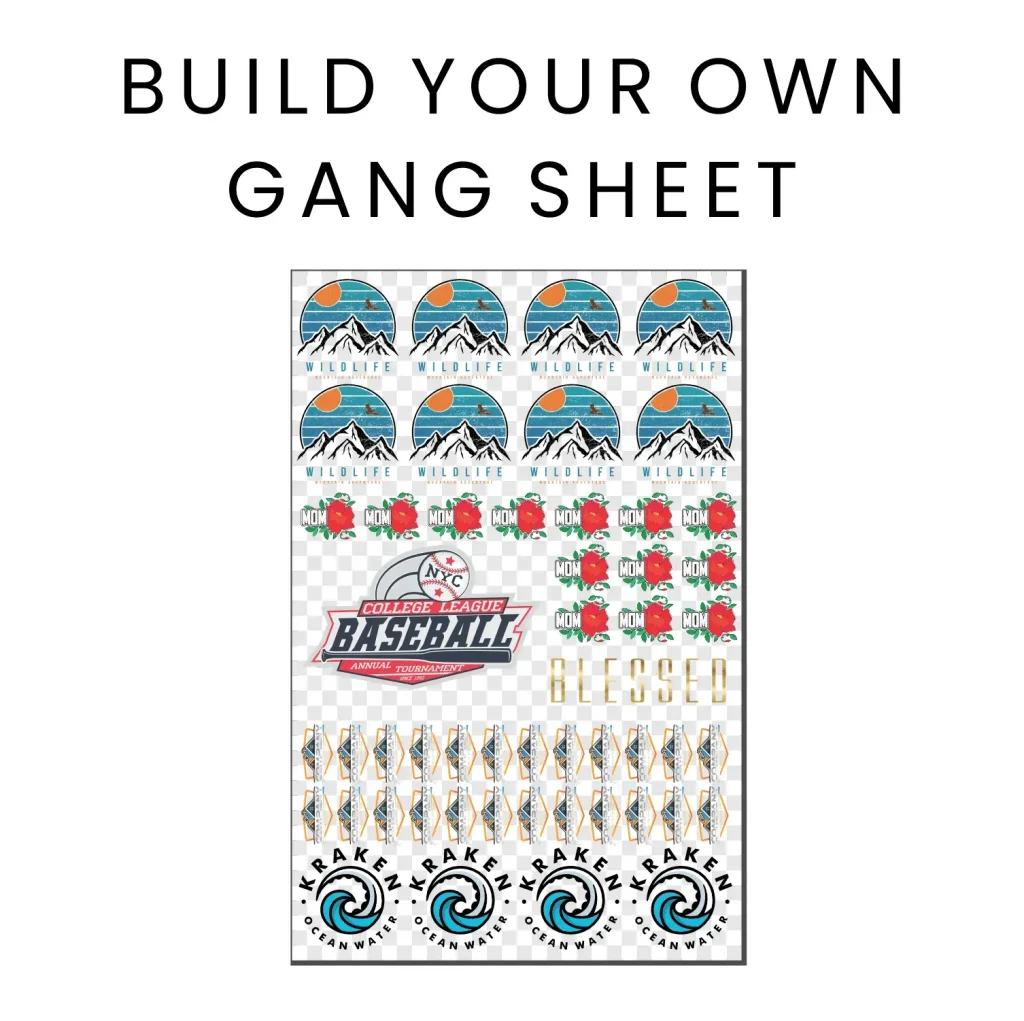

In the competitive realm of digital printing, the **DTF Gangsheet Builder** stands out as an essential tool for optimizing Direct-to-Film (DTF) printing workflows. This innovative solution allows users to efficiently group multiple images on a single print job, dramatically enhancing printing efficiencies and reducing waste. With DTF printing gaining momentum for its ability to produce vivid designs on various fabric types, the Gangsheet Builder becomes crucial for businesses looking to create custom merchandise quickly and effectively. By utilizing this tool, print providers can cater to diverse production demands while maintaining the highest quality standards. Whether you’re in the apparel industry or exploring fabric printing for promotional items, understanding the DTF Gangsheet Builder is your gateway to success in this dynamic creative landscape.

The concept of a **DTF Gangsheet Builder** can also be described as a specialized software that optimizes the gangsheet printing process within Direct-to-Film technology. This advanced tool streamlines the arrangement of multiple graphics on a single film sheet, enhancing printing efficiencies and ensuring minimal waste. Commonly utilized in custom fabric printing, this builder supports businesses in creating tailored merchandise in an organized and cost-effective manner. By offering features such as color management and size customization, it’s designed to suit various printing needs, from intricate apparel designs to larger promotional graphics. Embracing gangsheet printing practices can significantly benefit those looking to improve their production capabilities and optimize results in the custom merchandise market.

Understanding DTF Printing

Direct-to-Film (DTF) printing has revolutionized the fabric printing industry by allowing imprints of vibrant colors and intricate designs directly onto a specialized film before transferring them onto various materials. Unlike traditional techniques, DTF printing utilizes a unique approach that adheres the designs to fabrics using a heat press, resulting in long-lasting products that resist fading and wear. This method is highly versatile, making it an ideal solution for businesses aiming to deliver custom merchandise that appeals to a wide range of aesthetics.

The technology behind DTF printing involves several steps, including printing the design on a film with specially formulated inks, applying an adhesive powder, and then curing the design with heat. The result is a durable transfer that can be applied to multiple fabric types, including cotton, polyester, and blends. Businesses that leverage this technology enjoy the ability to create high-quality products efficiently, maximizing both design potential and market competitiveness.

What Is a Gangsheet in Fabric Printing?

A gangsheet is an essential tool in modern fabric printing that streamlines the process by allowing multiple designs to be printed on a single sheet of film. This technique not only enhances printing efficiency but also significantly reduces material waste and costs. By grouping several images together, printers can complete larger jobs with fewer resources, making gangsheet printing a favorite among print shops looking to optimize production.

Using gangsheet printing, businesses can achieve a variety of outputs – from custom logos on apparel to complex artwork for promotional items. This approach requires careful planning and design layout to ensure that every image remains distinct and undistorted during the printing process. The ability to pull together various projects into a single print run ultimately maximizes productivity and caters to the growing demand for rapid turnaround times in the competitive fabric printing market.

Key Features of a DTF Gangsheet Builder

A DTF Gangsheet Builder is specifically designed to enhance the experience of fabric printers by simplifying the layout process. One key feature is its intuitive design tools that allow users to arrange multiple images seamlessly on a single sheet. This feature ensures that each design is efficiently spaced, preventing overlaps that can compromise print quality. Furthermore, by adjusting the layout in the software, users can easily handle various project requirements without the need for time-consuming manual adjustments.

Another critical feature of the DTF Gangsheet Builder is its color management capabilities. This feature allows print designers to accurately preview how colors will appear on different fabrics, ensuring that the final product closely aligns with client expectations. It also enables the adjustment of colors in real-time, which is essential when dealing with diverse fabric types that may absorb inks differently. Overall, these features collectively contribute to a more streamlined and high-quality printing process.

Benefits of Utilizing a DTF Gangsheet Builder

Integrating a DTF Gangsheet Builder into your printing workflow presents numerous advantages, starting with cost savings. Since designs can be consolidated onto a single sheet, businesses reduce their film and ink usage, leading to lower material costs. This efficiency translates into increased profitability, especially when handling large orders for custom merchandise. Additionally, print shops can pass these savings onto customers, making their services more competitive in the market.

Time efficiency is another crucial benefit. The DTF Gangsheet Builder simplifies the setup process, allowing users to quickly prepare their designs for printing. This reduction in setup time means faster turnaround on orders and the ability to take on more projects simultaneously. As a result, businesses can increase their output and cater to a wider customer base without sacrificing quality—a vital aspect in today’s fast-paced fabric printing industry.

Exploring Use Cases for DTF Gangsheet Builder

The versatility of the DTF Gangsheet Builder becomes apparent when exploring its various use cases. For instance, in apparel printing, businesses can create everything from simple logos to intricate designs on T-shirts, hoodies, and activewear. Utilizing gangsheet printing, they can quickly produce multiple garments with diverse designs while maintaining high-quality outcomes, making this tool indispensable for clothing manufacturers looking to keep up with contemporary fashion demands.

Moreover, the DTF Gangsheet Builder proves invaluable in the realm of custom merchandise. Businesses can leverage this technology to create promotional products such as tote bags, hats, and mugs, ensuring that every piece reflects the brand’s identity. The ability to print multiple designs on a single gangsheet allows for creative flexibility while remaining cost-effective, thus expanding market reach and enhancing customer satisfaction across different promotional avenues.

Maximizing Success with DTF Gangsheet Builder Best Practices

To maximize the potential of the DTF Gangsheet Builder, implementing best practices is essential. One fundamental practice is starting with high-quality designs—using high-resolution files ensures that every detail is captured during printing. Clarity and vibrancy in the final product rely on the quality of the starting material, so investing in good design software and resources can significantly improve overall output quality.

Experimentation also plays a significant role in improving the use of the DTF Gangsheet Builder. Different fabric types require unique printer settings, and inconsistency in these settings can lead to unsatisfactory results. Taking the time to adjust and test various parameters, including temperature, pressure, and time settings, can yield remarkable improvements in print quality. Regular maintenance of printing equipment is another vital aspect. Keeping printers clean and functioning well will help ensure consistent quality and further establish a reliable output for all types of fabric printing projects.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance Direct-to-Film printing?

The DTF Gangsheet Builder is a specialized software tool designed to optimize Direct-to-Film (DTF) printing by allowing users to arrange multiple designs onto a single sheet. This approach maximizes printing efficiencies, reduces material waste, and enhances workflow for fabric printing projects, making it ideal for businesses looking to produce high-quality custom merchandise.

How does gangsheet printing work in conjunction with the DTF Gangsheet Builder?

Gangsheet printing with the DTF Gangsheet Builder involves placing several images on one film sheet before the printing process. This method optimizes resource usage and minimizes costs, allowing businesses to efficiently print multiple designs at once, leading to faster turnaround times for custom fabric printing.

What are the primary benefits of using a DTF Gangsheet Builder for fabric printing?

Using a DTF Gangsheet Builder offers several benefits for fabric printing, including significant cost efficiency by reducing the amount of film and adhesive used, time savings through streamlined design processes, and versatility across various fabric types. This makes it suitable for a broad range of applications, from apparel to promotional merchandise.

Can the DTF Gangsheet Builder be used for creating custom merchandise?

Yes, the DTF Gangsheet Builder is highly effective for creating custom merchandise. By arranging multiple designs on a single gangsheet, businesses can efficiently produce high-quality printed items such as branded apparel, promotional gifts, and other fabric-based products, ensuring cost-effectiveness without sacrificing quality.

What features should I look for in a DTF Gangsheet Builder to improve printing efficiencies?

Key features to look for in a DTF Gangsheet Builder include design layout tools for optimal spacing, advanced color management options for accurate prints, size customization capabilities to accommodate different design dimensions, and print quality optimization features. These tools collectively enhance the efficiency and quality of the DTF printing process.

What best practices should I follow when using a DTF Gangsheet Builder for successful printing?

To achieve successful outcomes with a DTF Gangsheet Builder, start with high-resolution designs, experiment with printer settings tailored to different fabric types, and ensure regular maintenance of your printing equipment. Following these practices will greatly improve print quality and overall workflow efficiency in your fabric printing operations.

| Key Feature | Description |

|---|---|

| DTF Printing | Direct-to-Film printing method for vibrant and detailed designs on fabrics. |

| Gangsheet Technique | Combines multiple images onto one film sheet to optimize printing efficiency. |

| Design Layout | Tools for arranging designs to ensure optimal spacing and alignment. |

| Color Management | Ensures accurate color representation based on fabric types. |

| Size Customization | Adjustable dimensions for fitting specific job requirements. |

| Print Quality Optimization | Optimizes print resolution for clear and detailed outputs. |

| Cost Efficiency | Reduces film and adhesive waste, leading to cost savings. |

| Time-Saving | Streamlines the design and printing process for quicker orders. |

| Versatility | Compatible with various fabrics for diverse product creation. |

Summary

The DTF Gangsheet Builder is a powerful solution for businesses looking to enhance their fabric printing workflows. By empowering users to effectively manage multiple designs on a single sheet, it facilitates efficient use of materials and boosts productivity. Understanding the features and benefits of the DTF Gangsheet Builder can transform your printing process, aligning it with the demands of today’s competitive market. As you explore the possibilities within custom apparel and merchandise creation, remember that mastering this tool will optimize your operations, ensuring high-quality results and satisfied customers.