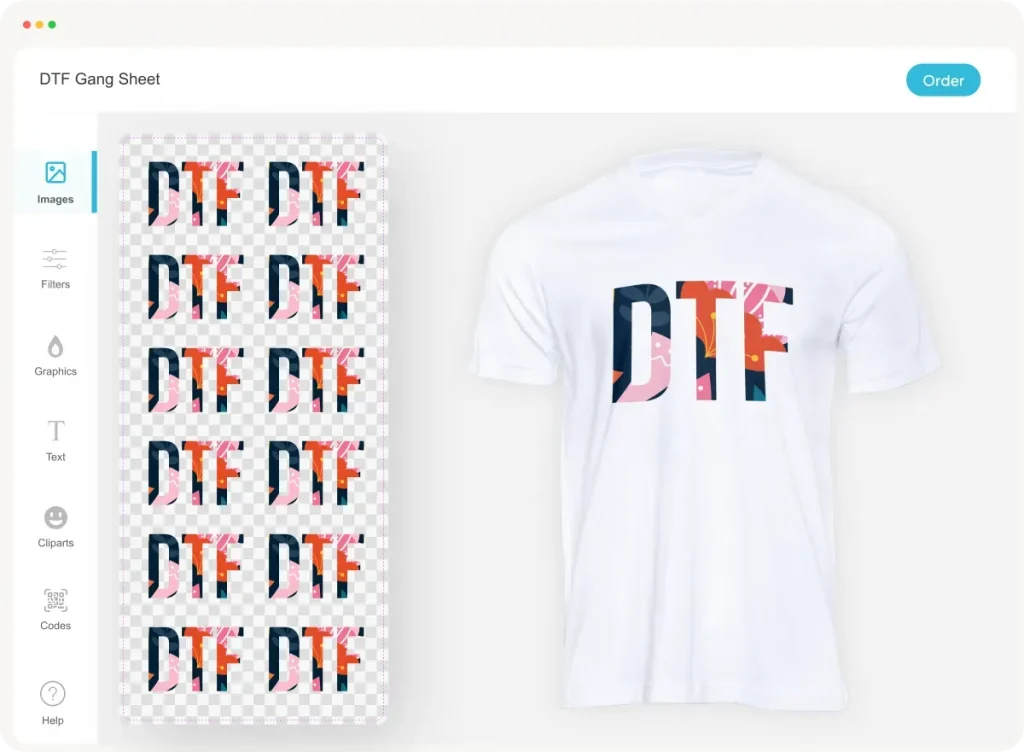

DTF gangsheet builder is redefining how print shops approach garment customization by organizing multiple designs on a single sheet and applying consistent workflow templates, enabling operators to move from concept to production with unprecedented clarity, repeatability, and quality control across every batch. By leveraging DTF gangsheet templates and DTF workflow templates, businesses can dramatically reduce setup time, minimize errors, and speed production from prepress to finishing, while providing scalable templates that grow with demand. This approach supports a quick turnaround and boosts production efficiency across small shops and growing production lines alike, aligning with the DTF printing workflow to translate creative ideas into repeatable results with less guesswork and with tighter alignment between art, color, and printing parameters. With template-driven layouts, integrated color management, and predefined print and curing parameters, the system preserves quality while scaling output across orders and batch runs, helping operators standardize routine jobs and minimize variability. Adopting a structured gangsheet design and processing strategy helps teams improve scheduling, reduce waste, and deliver consistent, on-brand transfers to customers, even when juggling multiple designs and different garment types.

In practice, you can think of this system as a sheet-based production tool that consolidates multiple designs onto one transfer panel, streamlining prepress tasks, color management, and sequencing. Rather than a single feature, it’s a holistic, gangsheet–driven workflow framework that aligns artwork, materials, and machine settings to produce consistent results. This approach ties into broader DTF printing workflow concepts, such as reusable template libraries, automation, and standardized curing and finishing parameters, all aimed at predictable turnaround and dependable output.

DTF Gangsheet Templates: Efficient Layouts for Waste-Minimization

DTF gangsheet templates enable the simultaneous layout of multiple designs on a single sheet, optimizing ink usage and reducing material waste. By planning placements, safe zones, and color separations in advance, shops can achieve faster prepress times and lower production costs. The result is a more predictable workflow where each job follows a proven pattern, helping you meet tighter deadlines without sacrificing quality.

Using templates also supports quick turnaround by standardizing how designs are placed, how margins are respected, and how color management is applied. When combined with a well-maintained library of templates, designers can rapidly assemble gang sheets for various garment types, sizes, and placements, while preserving consistent output and minimizing errors that slow down production.

DTF Gangsheet Builder: Quick Turnaround through Repeatable Workflows

A DTF gangsheet builder provides a repeatable system for layout, color management, and print parameters. It moves beyond a simple design tool by enforcing practical design rules and workflow templates that streamline each step from artwork import to final transfer preparation. The builder’s emphasis on consistency and speed helps teams hit tight deadlines with less rework.

Key features to maximize quick turnaround include a growing template library, auto-layout and spacing controls, color management presets, and batch processing capabilities. By automating routine tasks and enabling seamless integration with order management, the builder reduces setup times and ensures that every job adheres to a dependable standard.

DTF Printing Workflow: From Prepress to Transfers

DTF printing workflow covers the full path from design prep to final transfer. This includes design checks, color management, gangsheet layout, printing, film application, curing, and finishing. A structured workflow ensures that each phase proceeds in a predictable sequence, helping operators coordinate tasks and minimize delays across the production line.

In practice, aligning the DTF printing workflow with templates and presets reduces bottlenecks and reworks. Standardized settings for curing, ink sets, and film types mean that proofs, tests, and first-run pieces are more likely to meet expectations, accelerating both job acceptance and delivery timelines while supporting consistent production efficiency.

DTF Workflow Templates: Standardization for Consistent Quality

DTF workflow templates encode the ideal sequence of steps, roles, and checks that drive reliable outcomes. By defining color management practices, print parameter presets, and prepress validation in template form, shops can scale operations without losing the quality that customers expect. This standardization is especially valuable when handling multiple orders with similar requirements.

Using templates also simplifies training and onboarding, as new staff can execute tasks based on proven templates rather than improvising each time. As equipment and materials evolve, updated templates ensure the entire team stays aligned, maintaining quick turnaround times and high production efficiency across growing volumes.

Template-Driven Design for Quick Turnaround and Production Efficiency

A template-driven approach accelerates the design-to-production cycle by reducing prepress time and enabling fast proofs. Designers can populate gangsheet layouts with confidence, knowing that the underlying templates enforce spacing, color mapping, and print order sequencing. This consistency shrinks the back-and-forth needed to finalize client approvals.

Beyond speed, templates support higher production efficiency by enabling batch processing and reuse. When orders land that share common garment types or placements, templates let teams apply standardized parameters automatically, lowering the risk of human error and freeing up staff to focus on optimization and quality checks.

Practical Guidance: Maximizing Efficiency with DTF Templates

Real-world gains come from balancing lean template sets with scalable growth. Start with a core library of templates that cover your most common orders, then expand as new patterns emerge. This approach supports quick turnaround while preventing template complexity from spiraling.

Regular preflight, color calibration, and automated export workflows further enhance production efficiency. By keeping templates aligned with your printer, film system, and RIP requirements, you lower rework rates and improve consistency across large print runs, delivering reliable results to customers on time.

Frequently Asked Questions

How can a DTF gangsheet builder help achieve quick turnaround with DTF gangsheet templates?

A DTF gangsheet builder speeds up turnaround by using template-driven layouts and standardized print parameters. Leveraging DTF gangsheet templates ensures consistent layouts across jobs, reduces prepress time, and accelerates proofs and approvals while maintaining quality.

What features of a DTF gangsheet builder drive production efficiency through DTF workflow templates?

Key features include a growing template library, auto-layout and spacing, color management with ICC profiles, predefined print and curing parameters, batch processing, and seamless export and integration. Together, these support predictable production and higher production efficiency.

How do DTF printing workflow and DTF workflow templates work inside a DTF gangsheet builder?

They standardize each stage—from artwork prep to finishing—by applying repeatable templates. This reduces miscommunication, speeds handoffs, and ensures every job follows a consistent, efficient DTF printing workflow.

Why use DTF gangsheet templates in a DTF gangsheet builder for batch orders?

DTF gangsheet templates enable rapid layout decisions and consistent color management across multiple designs. This boosts production efficiency, lowers rework, and supports quick turnaround for batch orders.

How can you optimize color management and curing in a DTF gangsheet builder to speed up production?

Map colors to printer inks with ICC profiles, use standardized color separations, and apply curing presets. The builder’s presets minimize post-print adjustments, speeding up the workflow without sacrificing quality.

What is a practical six-step workflow for using DTF gangsheet templates to improve turnaround?

1) Gather artwork and specs. 2) Select a DTF gangsheet template. 3) Preflight designs. 4) Arrange on the gangsheet. 5) Configure color management and print/cure parameters. 6) Preview, print, cure, and perform post-production checks to ensure consistency and fast turnaround.

| Topic | Key Points |

|---|---|

| What is a DTF gangsheet builder? |

|

| Why it matters for quick turnaround |

|

| What makes a great DTF gangsheet builder |

|

| How to use DTF gangsheet templates in practice |

|

| DTF printing workflow and template-driven efficiency |

|

| Practical tips to maximize production efficiency |

|

| Case study highlights |

|

| Best practices for avoiding common pitfalls |

|

Summary

DTF gangsheet builder technology reshapes how print shops approach garment customization, enabling template-driven layouts, consistent color management, and standardized production steps that deliver quick turnarounds without sacrificing quality. By leveraging DTF gangsheet templates and workflow templates, businesses can reduce setup time, lower waste, and scale operations. The approach supports both small shops and growing production lines, promoting efficiency, predictability, and improved customer satisfaction through repeatable, high-quality outcomes.