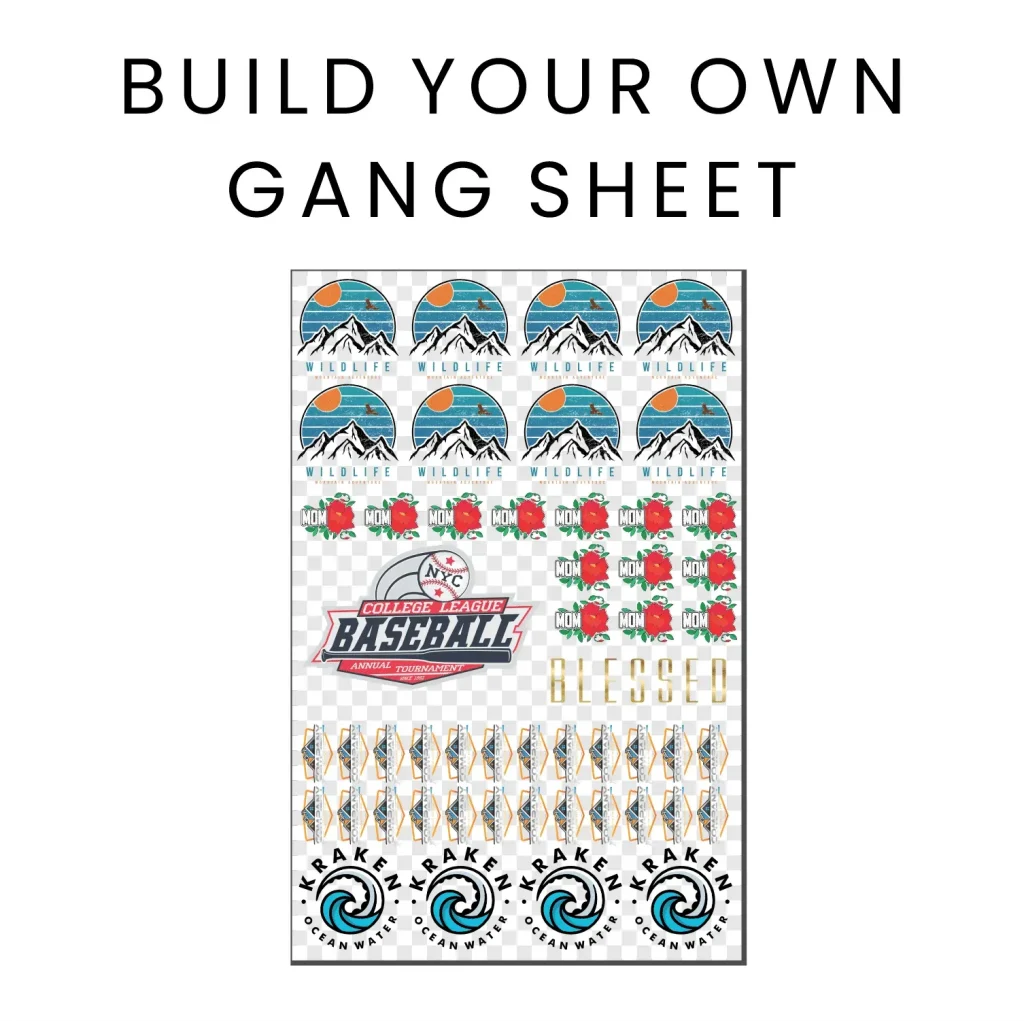

DTF Gangsheet Builders are transforming the landscape of digital printing by streamlining the production of customized apparel. As part of the Direct-to-Film printing process, these innovative tools allow multiple designs to be printed simultaneously on a single sheet, significantly boosting printing efficiency and reducing waste. By integrating digital printing technology, businesses can now offer vibrant, durable prints that cater to a growing demand for personalized products. Moreover, the use of DTF gangsheet builders is paving the way for sustainable printing solutions, as they often involve eco-friendly materials and practices. This evolution in customized apparel production not only meets consumer demand but also positions companies as frontrunners in the eco-conscious market.

The emergence of DTF gangsheet builders signifies a major leap in digital printing advancements, making the production of custom designs more viable than ever. This technology, known for its efficiency in handling customized apparel production, allows for optimized layouts that enable printers to maximize their output. Furthermore, with a focus on sustainable printing solutions, these builders are increasingly utilizing eco-friendly methods and materials. As the industry evolves, efficient printing processes and the ability to produce unique designs will redefine how businesses operate in the digital printing sector. Understanding these dynamics is crucial for those looking to stay ahead in a rapidly changing market.

The Advantages of DTF Gangsheet Builders in Digital Printing

DTF gangsheet builders have become a game-changer in the world of digital printing, particularly through their ability to offer cost-effective solutions that meet the increasing demand for custom designs. By enabling the simultaneous printing of multiple designs on a single sheet, companies can significantly reduce material waste while maximizing their production output. This not only streamlines the manufacturing process but also allows smaller businesses to remain competitive against larger print shops that have traditionally dominated the market.

Moreover, the time saved by using DTF gangsheet builders translates into quicker turnaround times for clients, which is a critical factor in today’s fast-paced market. This efficiency means that businesses can take on more jobs and respond swiftly to customer requests, ultimately leading to improved customer satisfaction and loyalty. As the demand for customized apparel grows, the role of DTF gangsheet builders in meeting these needs is more important than ever.

Recent Technological Innovations in DTF Printing

The rapid advancements in DTF printing technology have led to a range of innovative solutions designed to enhance print quality and efficiency. One significant breakthrough is the development of specialized inks and films that not only improve the vibrancy of prints but also their durability on various fabric types. This has positioned DTF printing as a viable alternative to traditional printing methods like screen printing and direct-to-garment printing, giving businesses an edge in delivering high-quality finished products.

Additionally, the integration of software solutions that optimize gangsheet layouts allows for more efficient use of materials and reduces setup times across print runs. It streamlines the design process and allows for automated arrangements that minimize waste, ensuring that businesses can print efficiently while maintaining exceptional quality standards. These innovations exemplify how progress in digital printing technology is reshaping production in the apparel industry.

Sustainability Trends in Digital Printing

As sustainability takes center stage within various industries, digital printing is striving to adapt and evolve. The push for eco-friendly practices has led many manufacturers to develop DTF gangsheet builders that utilize sustainable materials, such as biodegradable inks and recyclable films. This not only caters to environmentally-conscious consumers but also helps printing businesses align with global sustainability goals, promoting a positive image in a competitive marketplace.

Moreover, these sustainable printing solutions often provide additional financial benefits, as businesses can reduce waste and energy consumption through optimized processes. By investing in green technologies, companies in the DTF printing sector are not only being responsible stewards of the environment but also gaining a competitive edge that appeals to a growing segment of the market that prioritizes eco-friendliness in their purchasing decisions.

The Growing Market for Direct-to-Film Printing

The global market for Direct-to-Film (DTF) printing is expanding at an unprecedented rate, fueled by the demand for personalized and customized apparel. As consumers increasingly seek unique clothing options, businesses are turning to DTF technology to meet and exceed these expectations. This trend is anticipated to propel the DTF printing segment to a compound annual growth rate (CAGR) of over 25% in the coming years, positioning it as a dominant force in the digital printing landscape.

In response to this growth, many key industry players are investing heavily in research and development to enhance their DTF offerings. This includes the creation of innovative printers and software designed specifically for high-volume production, thereby attracting a broader range of clients. As the market evolves, those businesses that adopt and integrate DTF printing technology into their operations will likely lead the charge, setting new standards for quality and efficiency that will shape the future of customized apparel production.

Quality Improvements in DTF Printing Technology

One of the major factors contributing to the rising popularity of DTF printing is the notable quality enhancements observed in recent years. With the advent of advanced coatings and specialized inks, the adhesion of printed designs to fabrics has substantially improved. This results in prints that are not only more vivid but also last longer, thus enhancing customer satisfaction and reducing the rate of returns due to quality issues.

Furthermore, the adoption of cutting-edge film technology ensures that prints remain sharp and detailed, making DTF an appealing option for high-end fashion brands looking to maintain a distinct aesthetic. As companies continue to invest in these quality improvements, DTF printing is poised to solidify its position as a leading method for customizing apparel, providing a perfect blend of durability and vibrancy that resonates with consumers.

Future Prospects for DTF Gangsheet Builders

Looking ahead, the future of DTF gangsheet builders appears exceptionally bright. As more companies embrace the capabilities of this technology, we can expect further innovations that refine the printing process and enhance overall productivity. This may include advancements in automation, which would allow for even greater efficiencies in handling multiple designs simultaneously, ultimately leading to lower operation costs and higher profit margins.

In addition to technological progress, the increasing demand for personalized and sustainable products will continue to drive the DTF printing market forward. As consumer preferences evolve, businesses that stay ahead of the trends and leverage the benefits of DTF gangsheet builders will not only thrive but also set the stage for the next wave of digital printing advancements. Keeping pace with these developments will be essential for businesses aiming to remain competitive in this dynamic and rapidly changing industry.

Frequently Asked Questions

What are DTF Gangsheet Builders and how do they work in digital printing?

DTF Gangsheet Builders are specialized tools that enable the simultaneous printing of multiple designs on a single film sheet using Direct-to-Film (DTF) technology. This approach significantly reduces setup time and production costs by allowing print shops to maximize efficiency and minimize waste in customized apparel production.

How do DTF Gangsheet Builders improve printing efficiency in Direct-to-Film printing?

DTF Gangsheet Builders enhance printing efficiency by promoting batch processing, which allows print businesses to streamline their workflow and reduce idle time during production. This is particularly beneficial for smaller operations aiming to increase output without the need for expensive machinery.

What advancements in printing quality can be achieved with DTF Gangsheet Builders?

Recent advancements in DTF technology and gangsheet builders have led to improved print quality through better ink adhesion and vibrant color outputs. The specialized coatings on transfer films enhance durability, making prints produced with DTF methods stand out against traditional printing techniques.

What role does sustainability play in the use of DTF Gangsheet Builders?

Sustainability is increasingly important in the printing industry, and many DTF Gangsheet Builders now utilize eco-friendly inks and films. This shift not only meets the demand for sustainable printing solutions but also helps reduce the environmental impact of customized apparel production.

How is the market for DTF printing and Gangsheet Builders expected to grow in the coming years?

The DTF printing market is projected to grow at a compound annual growth rate (CAGR) of over 25%, driven by rising demand for custom apparel and personalized products. This growth underscores the importance of DTF Gangsheet Builders as businesses adapt to trends in digital printing technology.

Which companies are leading the development of DTF Gangsheet Builders?

Leaders in DTF printing technology and gangsheet builders include companies like Epson and Mimaki, which are innovating by releasing high-quality DTF-compatible printers and integrating advanced software solutions. These advancements are crucial for optimizing gangsheet layouts and improving production efficiency.

| Key Aspect | Description |

|---|---|

| Efficiency Improvements | Batch processing allows print shops to enhance throughput and minimize idle time, ideal for scaling production. |

| Quality Enhancements | Advancements in inks and films lead to higher durability and vibrancy in prints, standing out against traditional methods. |

| Market Growth Trends | The DTF printing market is projected to grow at a CAGR of over 25%, driven by demand for custom apparel. |

| Sustainability Focus | Many DTF gangsheet builders now use eco-friendly materials, catering to the environmentally-conscious market. |

| Key Industry Players | Companies like Epson and Mimaki are leading in innovations for DTF printing technology and gangsheet solutions. |

Summary

DTF Gangsheet Builders are redefining digital printing by optimizing efficiency, enhancing quality, and introducing sustainable practices. As manufacturers continually innovate with better inks, films, and software, DTF gangsheet builders provide a compelling solution for the growing demand in custom printing. The market’s dynamics, fueled by a strong interest in personalized products, position these builders at the forefront of the industry. Staying informed on these advancements will ensure that businesses maximize their potential and compete effectively in the evolving landscape of digital printing.