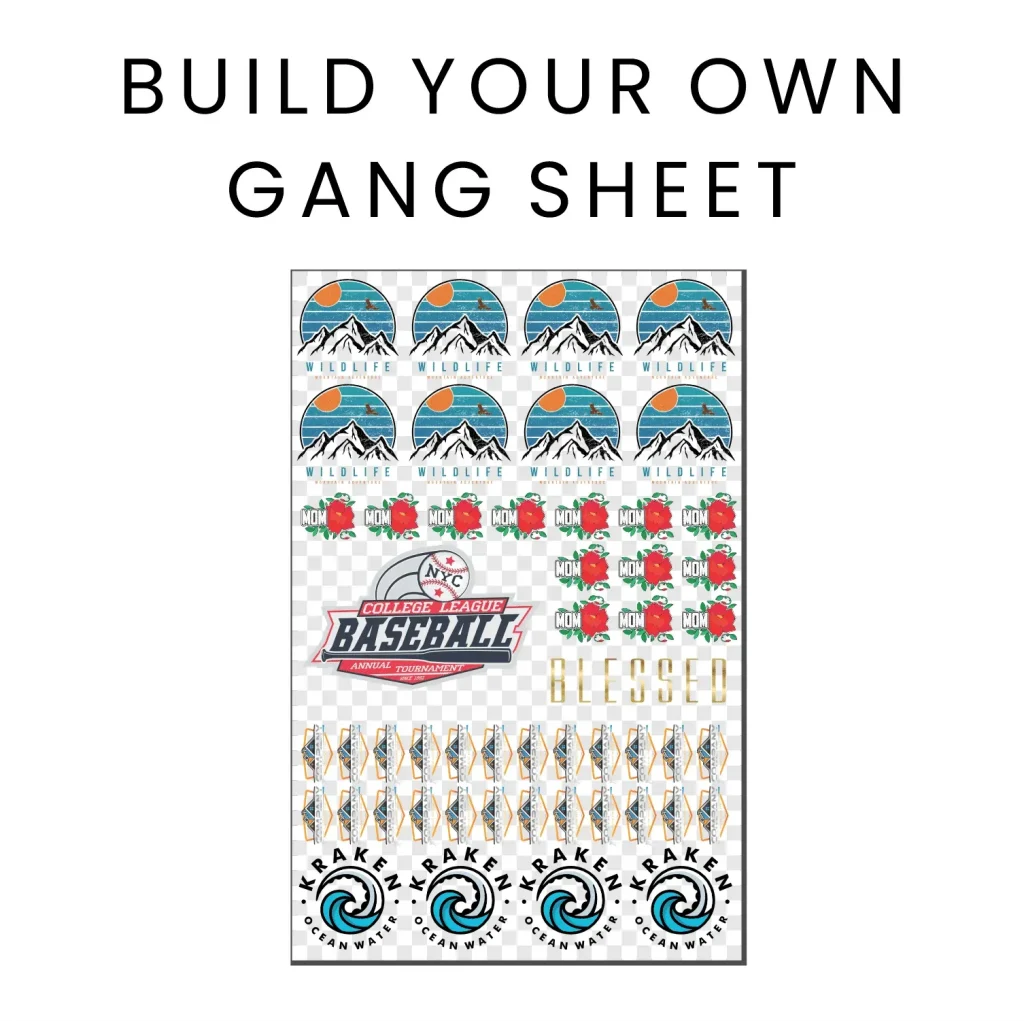

The DTF Gangsheets Builder is revolutionizing the world of custom apparel printing, allowing businesses to create stunning designs with unparalleled efficiency. This innovative tool simplifies the process of DTF (Direct-to-Film) printing, enabling users to assemble multiple designs on a single sheet known as gangsheets. With the rise in popularity of custom designs for clothing, the DTF Gangsheets Builder offers a solution that not only saves time but also reduces waste, making it an essential asset for any apparel entrepreneur. By utilizing this resource, designers can easily transfer their artwork onto textiles, ensuring high-quality heat press applications that stand out in the market. In today’s competitive landscape, mastering DTF printing through tools like the Gangsheets Builder opens new avenues for creativity and profitability.

The Direct-to-Film gangsheets creation process is an essential aspect of contemporary garment decoration techniques. Businesses in the custom apparel sector can leverage this advanced printing solution to efficiently produce vibrant graphics on fabric. Utilizing multi-design sheets aids in optimizing resources while achieving superior print quality, aligning well with trends in digital textile printing. This approach not only facilitates quicker turnarounds for custom designs but also enhances the production capabilities of designers looking to scale their operations. As heat transfer techniques become more commonplace, mastering the intricacies of DTF printing becomes increasingly crucial for those seeking to leave a mark in the dynamic fashion industry.

Understanding the Basics of DTF Printing

DTF printing, or Direct-to-Film printing, has emerged as a transformative technology in the world of custom apparel. This innovative technique allows for intricate designs to be printed on a special film, which can then be heat-transferred onto various fabrics. The primary advantage of DTF printing lies in its versatility—which supports a wide range of materials from cotton to polyester. This method is increasingly sought-after by apparel brands looking to create vibrant, high-resolution graphics that retain their quality wash after wash.

Notably, DTF printing operates through a process that involves printing the desired design onto this specially coated film using inkjet technology. After printing, an adhesive powder is applied to the wet ink. The film is then heated to cure the adhesive, which enhances the design’s stickiness once applied to fabric. This allows for a smooth transfer process, reducing the chances of peeling or fading over time, making it a preferred choice for custom designs in the textile industry.

The Advantages of Using DTF Gangsheets

Utilizing DTF gangsheets offers a variety of benefits that can significantly optimize your production workflow. By printing multiple designs on a single sheet, businesses can save both time and material, streamlining the printing process for various apparel items. This method not only reduces waste but also allows for more efficient use of the printer, leading to cost savings in the long run. Given the growing demand for custom apparel, being able to produce multiple designs concurrently eases the burden on resources and time.

Furthermore, DTF gangsheets are designed to enhance creativity without sacrificing quality. Each design on the gangsheets can be adjusted, rearranged, or resized, allowing for maximum flexibility in custom designs without the need for multiple separate prints. This flexibility lets you cater to specific client needs while ensuring overall production efficiency is maintained, making DTF gangsheets a game changer in the apparel printing industry.

Essential Tools for DTF Gangsheets Creation

Creating effective DTF gangsheets requires not only a clear understanding of the DTF printing process but also the right set of tools to facilitate design and printing. Graphic design software is crucial, as it allows you to create custom designs and arrange them effectively on gangsheets. Tools like Adobe Illustrator and CorelDRAW offer extensive features tailored for professional design work, including vector graphics that maintain clarity at any size. For beginners, user-friendly alternatives such as Canva or GIMP can also be used to assemble gangsheets.

In addition to design software, having the correct printing equipment is essential for successful DTF printing. This usually involves a high-quality inkjet printer compatible with DTF technology and appropriate films. Furthermore, investing in a reliable heat press machine is key. The heat press ensures the designs are transferred adequately to the fabric, providing long-lasting results. Together, these tools lay the foundation for creating stunning, customized apparel that satisfies client demands.

Finalizing Your DTF Design for Printing

Once your DTF gangsheets have been designed, the next step is to finalize your work in preparation for printing. This involves exporting your designs in suitable formats that maintain quality and integrity. PNG files preserve transparency, which is critical for complex designs, while TIFF files are excellent for high-resolution outputs. It’s essential to ensure that the colors are correctly calibrated for your printer to achieve the desired look on the fabric—as colors can sometimes vary between designs viewed on a screen and the final print.

Moreover, always double-check the dimensions and alignment of your designs on the gangsheet before you send them to print. Misalignment can lead to wasted materials and time if adjustments are needed post-printing. Preparing a test print allows you to assess the quality and clarity of your designs before the final run. This process prevents errors and ensures your final apparel meets professional standards.

Applying Finishing Touches After Printing

After printing your DTF gangsheets, it’s crucial to apply appropriate finishing touches to ensure the longevity and aesthetic quality of your designs. Carefully cutting out each design from the gangsheet is necessary, and attention should be paid to prevent any damage to adjacent graphics. This step requires precision to ensure each design maintains its integrity, especially around intricate areas of detailed graphics.

Following the cutting process, proper heat press application is vital for transferring the printed designs onto apparel. The settings on the heat press machine—temperature, pressure, and time—must be adjusted based on fabric type and DTF film used. Proper cooling timing is equally important; allowing the design to set properly can drastically prolong its lifespan and quality, ensuring your printed garments stand up to use and washing over time.

Frequently Asked Questions

What is a DTF Gangsheets Builder?

A DTF Gangsheets Builder is an online tool designed to help users create gangsheets for Direct-to-Film (DTF) printing. It allows designers to arrange multiple custom designs on a single sheet, optimizing space and materials for apparel printing.

How can I create custom designs using DTF Gangsheets Builder?

To create custom designs using a DTF Gangsheets Builder, start by selecting a design software to prepare your graphics. Next, use the builder to arrange your designs within the provided template dimensions, export it in a suitable format, and you’re ready to print!

What are the benefits of using DTF printing with gangsheets?

Using DTF printing with gangsheets provides significant advantages like printing multiple designs at once, reducing material waste, and saving time in the apparel printing process. This method ensures high-quality results and enhances productivity.

Can I use any printer with DTF Gangsheets Builder?

No, not all printers are compatible with DTF printing. It’s essential to use a printer that supports DTF technology, such as specific Epson or Brother models, to ensure optimal results when printing gangsheets.

What materials are suitable for heat press application of DTF gangsheets?

DTF gangsheets can be applied to a variety of fabrics including cotton, polyester, and blended materials. Ensure that the chosen heat press settings align with the fabric type to achieve the best adhesion and durability.

Where can I learn more about DTF printing and using Gangsheets Builder effectively?

You can explore YouTube tutorials, join dedicated forums like r/DTFprinters on Reddit, and check out instructional blogs on websites like Spoonflower to enhance your understanding and skills in DTF printing and gangsheets creation.

| Key Point | Details |

|---|---|

| What are DTF Gangsheets? | DTF gangsheets consist of multiple designs printed on a single sheet, which can be heat applied to fabrics. |

| Understanding DTF Printing | DTF printing uses a coated film to print high-resolution graphics, allowing for efficient design application. |

| Design Creation Process | Choose design software, set dimensions, arrange designs, and export in suitable formats like PNG or TIFF. |

| Utilizing Builder Tools | Custom builders like Avery and apps with DTF plugins simplify the design process. |

| Printing Techniques | Select a compatible printer, use a heat press, and follow proper application settings. |

| Post-Application Care | Allow prints to cool post-application and test for durability through washes. |

| Additional Resources | Explore YouTube tutorials and community forums for further tips and insights on DTF printing. |

Summary

DTF Gangsheets Builder is an essential tool for anyone looking to create custom designs in the world of apparel printing. By understanding the intricacies of DTF printing and following a detailed step-by-step approach, users can efficiently produce high-quality prints that cater to market demands. This guide equips you with the necessary knowledge and resources to navigate through design creation, printer selection, and application techniques. Embracing DTF gangsheets not only streamlines production but also elevates the standard of your custom apparel, ensuring you remain competitive in a thriving industry.