The DTF printing process, or Direct-to-Film printing, is revolutionizing the textile printing industry with its ability to produce intricate designs on a variety of fabrics with remarkable precision and vibrancy. This innovative method utilizes cutting-edge printing technology to transfer high-quality prints from film directly onto textiles, making it a go-to choice for fashion and merchandise production. From the initial design phase to the final heat transfer application, the DTF printing steps ensure a seamless workflow that is both efficient and reliable. As businesses seek effective fabric printing solutions, DTF printing emerges as a leader in the market, offering unmatched flexibility and stunning results. The advancements in DTF technology not only enhance print durability but also cater to the growing demand for high-quality textile products.

Also referred to as Direct-to-Film transfer, the DTF printing process involves a sophisticated method for applying designs onto fabric materials. With its capability to create detailed and vibrant images, this innovative printing technique has gained immense popularity among textile manufacturers and designers. By utilizing a straightforward approach that includes design creation, film printing, adhesive application, and heat transfer, DTF offers a unique combination of convenience and quality. As trends in fabric printing evolve, this technology stands out as a leading choice for custom apparel and specialty items. With ongoing innovations and improvements in printing technology, the prospects for DTF are brighter than ever, positioning it as a key player in the textile printing realm.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process has transformed the textile printing landscape, providing a versatile option for creating rich designs on various fabric types. DTF combines high-quality digital designs with innovative printing technology, enabling intricate patterns to be replicated efficiently. Unlike traditional printing methods that often require multiple setups, DTF allows for a seamless workflow where designs can be printed directly onto a specially-treated film, making it an attractive choice for many businesses within the fabric printing sector.

Furthermore, the DTF printing process stands out due to its ability to produce vibrant colors even on dark fabrics. This is made possible through the application of white ink, which forms a base layer that enhances overall color brightness. With such capabilities, businesses can meet diverse customer needs, offering full-colour personalized designs that cater to any textile application, from custom apparel to promotional items.

Key Steps in the DTF Printing Workflow

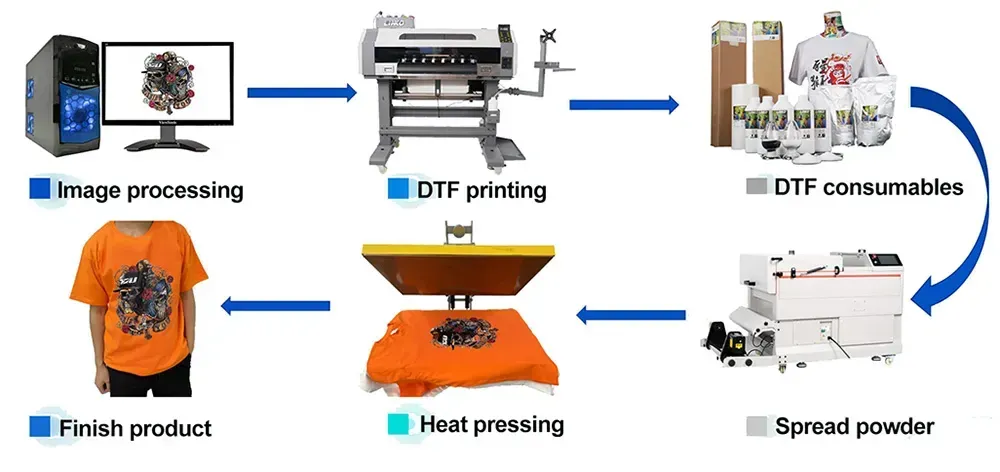

Navigating through the DTF printing workflow involves several key steps that ensure the creation of high-quality prints. Initially, the design phase is crucial, utilizing software like Adobe Illustrator to produce graphics at high resolutions. This allows for intricate details that can captivate the audience and enhance overall design quality. Following this, the process moves into the printing phase, where the design is printed onto a transfer film using specialized DTF printers equipped to handle pigment inks.

The next significant step is the application of hot-melt adhesive powder. This step is essential for ensuring that the printed design adheres effectively to the fabric during heat transfer. Whether done manually or via automation, precise application of the adhesive powder ensures durability and wash resistance of the final product. The final wave of the workflow concludes with the heat transfer to the fabric, where precision and temperature are meticulously monitored to achieve the desired outcome.

The Role of Quality in DTF Printing

Quality assurance is a cornerstone of the DTF printing process. Each stage from design creation to heat transfer carries a responsibility to maintain high standards, as this is critical to producing a finished product that satisfies customer expectations. Once the printing is complete, a thorough quality check is necessary to evaluate factors such as color fidelity and adherence strength. This meticulous attention to detail not only ensures the aesthetic appeal of the final design but also its durability in the face of washing and wearing conditions.

Moreover, recent advancements in materials specifically designed for DTF printing have further enhanced the quality of the output. Innovations in film and adhesive formulations provide better adherence and greater flexibility across a range of textiles. As the printing industry evolves, businesses must remain vigilant in adopting these innovations to stay competitive, delivering products that not only meet but exceed industry standards of durability and quality.

Innovative Technology in DTF Printing

The DTF printing technology landscape is marked by continuous advancements that enhance efficiency and output quality. Innovations in printing technology enable faster production times and reduce setup complexities, allowing businesses to respond swiftly to market demands. As technology evolves, DTF printers are now capable of utilizing cutting-edge pigments that provide heightened vibrancy and longevity, enhancing the overall appeal of printed textiles.

Additionally, these technological improvements contribute to more sustainable practices within the industry. As eco-friendly inks become more prevalent, DTF printing is seen as a leading solution for businesses aiming to adopt sustainable textile printing solutions. Innovations, therefore, do not merely focus on output precision but also on ecological responsibility, aligning with the growing consumer demand for sustainable products.

Exploring Market Opportunities with DTF Printing

The market for DTF printing is expanding rapidly, driven by a growing demand for personalization and custom printing solutions. Many businesses are leveraging this trend by offering unique fabric printing services that allow customers to express their individuality through textile designs. With the ability to print intricate patterns and vibrant colors on a variety of fabrics, DTF technology positions itself as a competitive player in both fashion and promotional goods markets.

Moreover, the versatility of DTF printing opens up opportunities for collaboration with designers, artists, and businesses seeking to translate their creative visions into physical products. As more industries embrace DTF printing, new niches are emerging, ranging from sports apparel to home textiles. This adaptability underscores the significance of DTF as not just a printing technique but as a fundamental component of modern fabric printing technology.

Future Trends in DTF Printing Technology

Looking ahead, the future of DTF printing technology appears promising, with anticipated growth in the innovation of processes and materials. As established patterns of productivity shift towards more efficient systems, the DTF printing landscape is likely to welcome enhancements such as advanced printer models that integrate artificial intelligence for optimized printing. These advancements could streamline operations, reduce waste, and enhance print accuracy.

In addition, sustainable practices will continue to shape the future of DTF printing. The integration of eco-friendly materials and processes is expected to propel DTF printing into new realms, catering to a socially conscious consumer base. As awareness of environmental impact rises, the shift towards sustainable inks, biodegradable films, and responsible production will be paramount. Such trends not only align with consumer preferences but also secure the longevity and acceptance of DTF technology in a rapidly evolving market.

Frequently Asked Questions

What is the Direct-to-Film (DTF) printing process?

The Direct-to-Film (DTF) printing process involves printing a design onto a special transfer film using water-based pigment inks, followed by applying an adhesive powder to bond the ink, and finally heat transferring this design onto fabric. This method allows for high-quality textile printing with vibrant colors and durability.

What are the key steps involved in DTF printing?

The key steps in the DTF printing process include: 1) Design Creation using graphic design software, 2) Printing the transfer film with specialized DTF printers, 3) Applying adhesive powder to the wet ink, 4) Heat transfer of the design to the fabric, and 5) Finishing touches, which may include additional curing and quality checks.

What types of fabrics can benefit from DTF printing solutions?

DTF printing can be applied to a wide range of fabrics, including cotton, polyester, blends, and more. This versatility makes DTF printing solutions ideal for various textile applications, from apparel manufacturing to promotional items.

How does DTF printing compare to traditional textile printing methods?

DTF printing offers several advantages over traditional textile printing methods, including faster production times, the ability to print complex designs, and enhanced durability of prints. Unlike screen printing, DTF does not require separate screens for each color, making it more cost-effective for small runs.

What are the latest innovations in DTF printing technology?

Recent innovations in DTF printing technology include advancements in eco-friendly inks, improved adhesive formulations, and enhanced film materials that offer increased durability and wash resistance. These technological improvements ensure high-quality prints that cater to the growing demand for sustainable practices.

Can anyone get started with the DTF printing process?

Yes, with the right equipment and software, anyone can get started with the DTF printing process. Key essentials include a specialized DTF printer, graphic design software, transfer film, and adhesive powder. By following the proper steps, even beginners can produce high-quality fabric prints.

| Step | Description |

|---|---|

| 1. Design Creation | Creating a digital design using software such as Adobe Illustrator, ensuring high resolution and quality. |

| 2. Printing the Transfer Film | Using specialized DTF printers to print the design onto PET film with pigment ink. |

| 3. Applying Adhesive Powder | Applying hot-melt adhesive powder to the wet ink and curing it to ensure good adhesion. |

| 4. Heat Transfer to the Fabric | Transferring the design to the fabric using a heat press, ensuring proper temperature and pressure. |

| 5. Finishing Touches | Performing additional curing and a quality check to enhance print durability. |

| Recent Developments | Innovations in materials and sustainability practices are shaping the future of DTF printing. |

Summary

The DTF printing process is a revolutionary technique in the textile printing industry, known for its ability to produce intricate and vibrant designs on a variety of fabrics. This method transitions from digital design creation through to final product application with precision. By utilizing advanced software for design, specialized printers for transfer film, and innovative adhesive applications, the process ensures durability and quality. The subsequent heat transfer solidifies the design onto the fabric, resulting in a product that is not only visually appealing but also withstands the rigors of everyday wear. With advancements in material technology and eco-conscious practices, the DTF printing process continues to evolve, offering exciting opportunities for creators and businesses alike as they navigate this expanding market.