In the realm of fabric printing, **DTF transfers** (Direct-to-Film) are revolutionizing the way custom designs are applied to garments. This innovative method enables artists and businesses to achieve stunning, high-resolution prints with remarkable color accuracy, making it an attractive option for anyone looking to enhance their fabric projects. Unlike conventional methods that restrict you to specific fabric types, DTF printing boasts versatility, allowing prints to adhere beautifully to a wide range of materials. For beginners eager to dive into the world of fabric printing techniques, this guide will unfold the essentials of DTF transfer printing and offer practical advice to ignite your creativity. Join us as we explore this cutting-edge technique that bridges the gap between complexity and usability.

Often referred to as Direct-to-Film printing, DTF transfers signify a modern approach to transferring images onto various fabrics, appealing to both novice and experienced printers alike. This versatile technique stands out from traditional fabric printing methods, effortlessly producing vibrant, detailed artwork that captivates the eye. For those seeking an entry point into the diverse landscape of fabric printing techniques, DTF transfer printing offers a simplified process, enhancing accessibility without compromising quality. As we navigate through the ins and outs of this innovative method, we’ll uncover tips and insights that can empower creators to bring their visions to life. Discover how adopting this contemporary method can transform your fabric printing endeavors and unlock new possibilities.

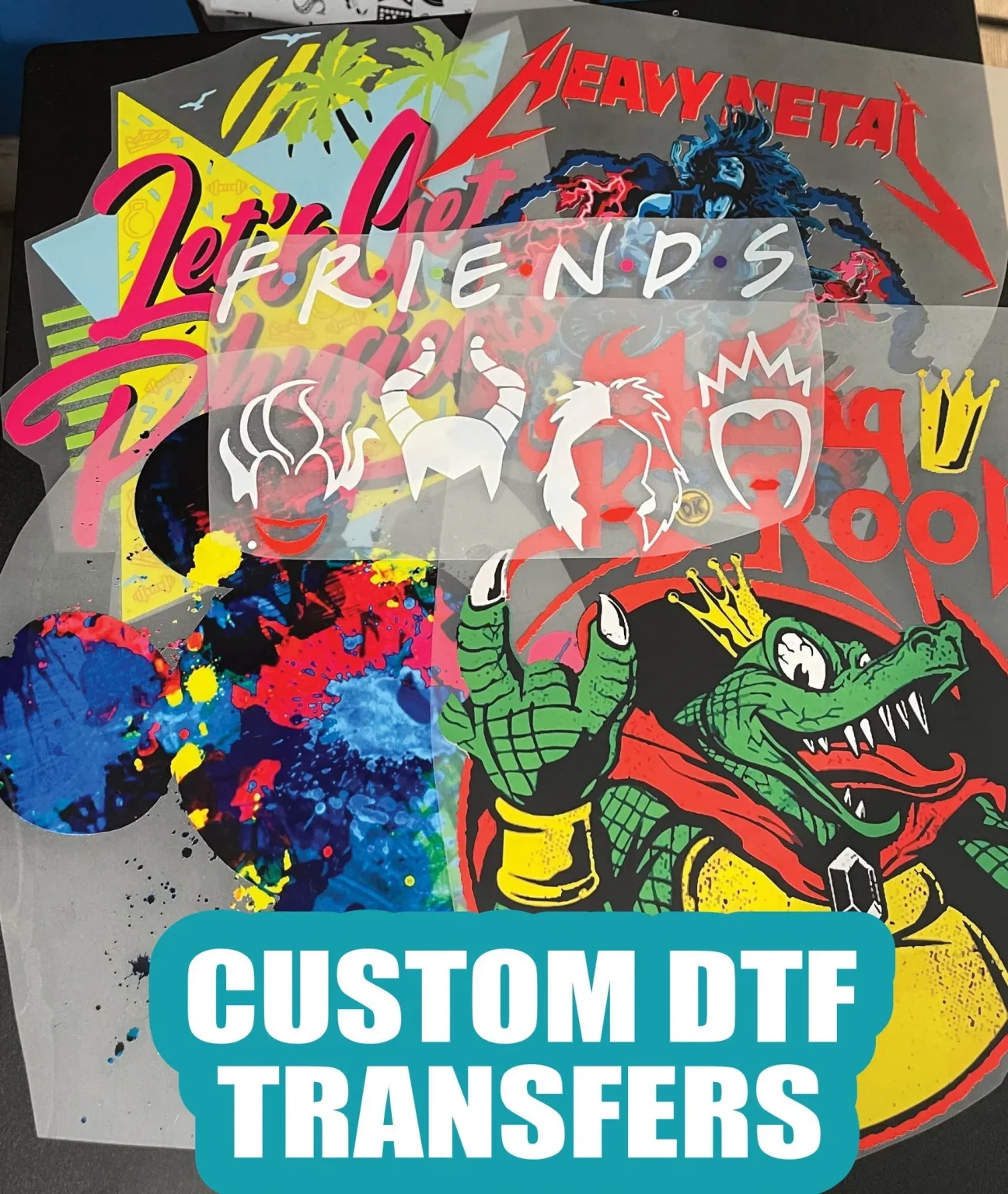

Understanding DTF Transfers: The Future of Fabric Printing

DTF transfers, or Direct-to-Film transfers, revolutionize the fabric printing industry by enabling vibrant color applications and intricate designs. This process involves printing your desired artwork on a special film which, when exposed to heat and pressure, adheres seamlessly to various types of fabrics. Unlike traditional methods, DTF printing provides more freedom to use diverse materials, including cotton, polyester, and blends, which means designers can explore a broader range of creative possibilities without being restricted by fabric type.

Furthermore, DTF transfer printing retains the quality and brightness of colors, offering results that are both durable and striking. With the rising interest from both DIY enthusiasts and professional printers, many are eager to adopt the DTF method, realizing its potential for a wide array of applications—from fashion apparel to personalized gifts. Understanding how DTF works is crucial for anyone looking to delve into modern fabric printing techniques, unlocking doors to new business opportunities and creative outlets.

Getting Started: A Beginner’s Guide to DTF Printing

For those new to DTF transfers, embarking on this printing journey requires understanding the essential equipment and supplies. At a minimum, you will need a DTF printer, DTF transfer film, adhesive powder, and a reliable heat press machine. Many beginners may feel overwhelmed by the variety of options available, however, it’s important to start with a steady plan and budget to ensure that you select the right tools for your projects. Beginners can learn basic printing techniques and gradually experiment with complex designs as their skills expand.

Additionally, there are numerous online resources, tutorials, and forums that provide invaluable guidance on best practices for DTF transfer printing. Engaging with communities of fellow printers not only enhances learning but can also inspire creativity and innovative design ideas. Remember, every expert was once a beginner, and mastering DTF techniques takes practice, patience, and an eagerness to explore the diverse applications of fabric printing.

The Benefits of DTF Transfer Printing Compared to Traditional Methods

One notable benefit of DTF transfer printing is its compatibility with a wide range of fabrics, allowing for more versatility than traditional printing methods like silk screen or heat transfer vinyl. This means that whether you are printing on cotton, polyester, or blends, the quality remains high and the results are vibrant. Unlike screen printing, which often requires a different setup for different colored inks and designs, DTF methods can simplify the printing process significantly, saving both time and resources.

Moreover, DTF transfers create a softer feel than many traditional prints, which is essential for comfort, especially in apparel. This feature appeals to many consumers who prefer their clothing to feel as good as it looks. As the demand for personalized fashion increases, DTF printing stands out as an excellent option for businesses aiming to provide quality products while maximizing design capabilities.

Innovations in DTF Technology: Enhancing Efficiency and Creativity

Recent advancements in DTF technology are paving the way for higher efficiency and improved quality in fabric printing. Companies like Snuggle are leading the charge by offering scalable solutions for mass production while maintaining exceptional print quality. With capabilities of producing thousands of DTF transfers daily, manufacturers are better positioned to meet the increasing market demand. Such innovations can help reduce lead times and elevate customer satisfaction, which is critical in the fast-paced world of fashion and custom printing.

In addition to output capabilities, technology enhancements are also focused on the printing process itself. Innovations like eco-friendly inks and improved adhesive powders contribute to a more sustainable production approach while preserving the overall integrity of prints. Adopting these modern technologies helps businesses not only stay competitive but also socially responsible. For those considering a venture into DTF, keeping abreast of these innovations is crucial for future-proofing their operations in a rapidly evolving industry.

Common Mistakes to Avoid When Starting DTF Transfers

As with any new venture, beginners often encounter common pitfalls when first experimenting with DTF transfers. One major mistake is overlooking the importance of proper printing settings and material compatibility. Ensuring that your printer is calibrated correctly and utilizing the appropriate film type is essential for achieving optimal results. Additionally, improper heat press settings can lead to unsatisfactory adhesion or fading of prints, which can be frustrating for newcomers. Taking the time to fully understand and test these variables can help mitigate these issues.

Another frequent oversight is the failure to prepare the fabric surface adequately before applying DTF transfers. Cleaning and pre-treating the fabric can significantly enhance the bond between the print and the material, leading to longer-lasting results. It’s crucial to read up on proper fabric care and handling as well as to conduct sample tests on different materials to find the most suitable options for your projects. By being aware of these common mistakes, beginners can elevate their DTF printing experience and produce high-quality final products.

Exploring Various Applications of DTF Transfers in Fashion and Beyond

DTF transfers offer a world of possibilities not just in fashion but also across various industries. From custom t-shirts to intricate design applications on bags and accessories, DTF printing caters to both personal projects and large-scale commercial needs. The ability to produce vibrant and detailed designs allows artists and brands to create unique identity pieces that stand out in a crowded market.

Moreover, the versatility of DTF transfers means they can be applied beyond typical fashion items. Areas like home decor, promotional products, and merchandise for events benefit significantly from the dynamic capabilities of DTF printing. Businesses can leverage this technology to personalize items for special occasions, creating lasting impressions through custom designs. The potential applications of DTF transfer printing are vast, and with each innovation in technology, the opportunities continue to expand.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a fabric printing technique where designs are printed onto a special film before being applied to garments using a heat press. This method allows for vibrant, detailed designs that can be transferred onto various fabric types, making it a versatile choice compared to traditional screen printing.

What is the difference between DTF printing and traditional screen printing?

The main difference between DTF printing and traditional screen printing lies in the application process. DTF transfers use a film to print designs before transferring them to fabric, allowing for more complexity and color variety. In contrast, traditional screen printing often limits designs to fewer colors and requires more setup for each print.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are highly versatile and can be used on various fabric types, including cotton, polyester, blends, and even some nylon fabrics. This flexibility makes DTF printing an excellent choice for diverse fabric printing projects.

What are the advantages of using DTF transfer printing?

DTF transfer printing offers numerous advantages, including vibrant color reproduction, the ability to print intricate designs, and compatibility with various fabric types. Additionally, DTF transfers are easier to manage in terms of production volume and efficiency, especially for businesses looking to scale.

What equipment do I need to start with DTF printing as a beginner?

To get started with DTF printing, beginners typically need a DTF printer, special DTF transfer film, a heat press, and DTF ink. It is also advisable to have design software for creating graphics tailored for DTF transfers.

How can I improve my DTF printing skills as a beginner?

Improving your DTF printing skills involves practice and exploration. Starting with basic designs, investing time in understanding your equipment, and experimenting with different fabric types will enhance your skills. Additionally, following online tutorials and forums dedicated to DTF transfers can provide valuable insights.

| Key Points | Details |

|---|---|

| Definition of DTF Transfers | DTF stands for Direct-to-Film transfers, a fabric printing method that allows intricate designs to be printed onto a special film for transfer to garments using heat. |

| Advantages of DTF Printing | DTF printing offers vibrant designs, versatility across materials, and does not limit production to a specific fabric type, unlike sublimation. |

| Recent Innovations | New trade services launched by Snuggle, capable of high-volume prints, respond to the growing demand for DTF printing solutions. |

Summary

DTF transfers have revolutionized the fabric printing landscape, merging creativity with efficiency. As a modern printing technique, DTF offers a plethora of opportunities for those involved in garment production, enabling them to create colorful and complex designs with ease. The versatility of DTF transfers allows them to be applied across various fabric types, which sets them apart from traditional methods such as screen printing and sublimation. With the recent advancements in DTF technology, including innovative services like those from Snuggle in Peterborough, it is clear that DTF transfers are becoming essential for businesses looking to enhance their production capabilities. This guide not only highlights the benefits of DTF printing but also encourages beginners to explore its potential in their own projects.