In the competitive world of fabric printing, DTF transfers have emerged as a revolutionary technique that combines efficiency with high-quality output. Standing for Direct to Film transfers, DTF printing allows for the vibrant replication of intricate designs onto various fabrics without the need for pretreatment, making it a favorable choice among crafters and businesses alike. Unlike traditional screen printing, which often requires extensive setup for bulk orders, DTF provides the versatility to handle small runs with ease. This blog aims to delve deeper into the intricacies of DTF transfers, comparing them with other popular methods like heat transfer vinyl and Direct to Garment printing. Whether you’re looking to produce unique promotional materials or custom garments, understanding DTF transfers can significantly enhance your printing endeavors.

When exploring the landscape of modern fabric decoration, terms like Direct to Film transfers, digital heat transfer, and film-based printing highlight the evolving methodologies available to enthusiasts and professionals alike. These alternative concepts represent a shift towards innovative fabric printing techniques that prioritize both quality and ease of use. By examining options such as DTF transfers alongside analog methods like screen printing and heat transfer vinyl, one can gain insights into the best practices for creating stunning, personalized designs. In this discussion, we will unpack the advantages of utilizing film-based approaches, showcasing their ability to meet intricate design needs while ensuring compatibility across a range of textiles. As you navigate the diverse options, the right choice in printing technology can elevate your projects and fulfill your creative visions.

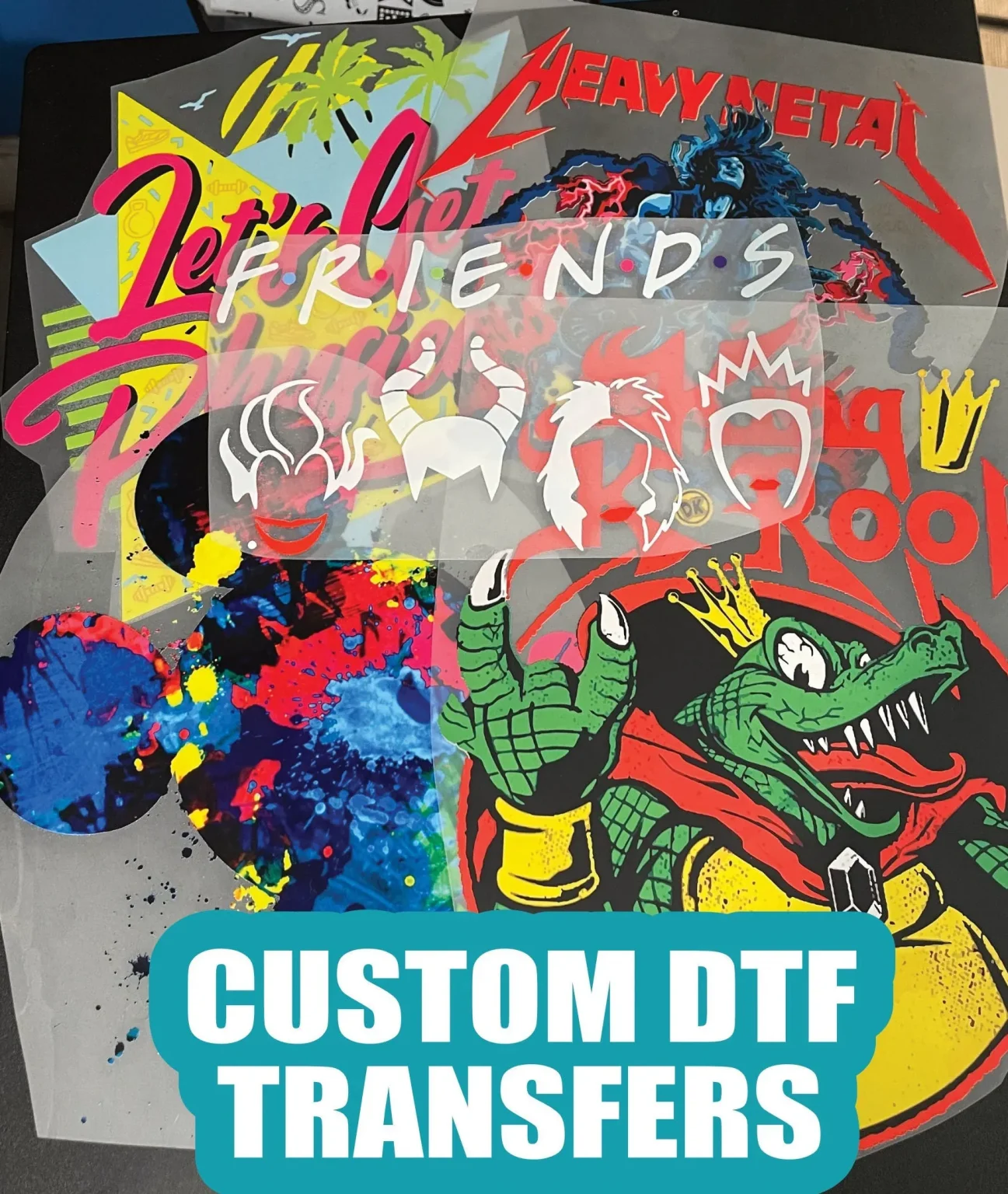

Understanding DTF Transfers and Their Unique Benefits

DTF transfers, or Direct to Film transfers, represent a notable innovation in the realm of textile printing. This method allows for the direct printing of intricate designs on a special film, which can then be transferred onto textiles using heat and pressure. Unlike traditional methods such as screen printing or Direct to Garment (DTG) printing that often involve complex pre-treatment of materials, DTF simplifies the process by eliminating these requirements. As a result, crafters and apparel businesses seeking high-quality prints find DTF transfers particularly appealing due to their efficiency and ease of use.

Another key advantage of DTF printing is its vibrant color reproduction and detail rendering. High-quality prints achieved through this technique boast exceptional color depth and sharpness, making it suitable for custom designs that demand precision. This is particularly advantageous for fashion and promotional industries, where aesthetic appeal is paramount. With the ability to print on various fabrics, including cotton, polyester, and blends, DTF offers versatility that appeals to businesses aiming to diversify their product offerings.

Comparing DTF Transfers to Screen Printing

Screen printing has long been a staple in the printing industry, particularly for large-scale production runs due to its economical pricing. However, it is not without drawbacks. The setup costs and the need for extensive manual labor can slow down production times, especially for smaller orders. In this context, DTF transfers provide an attractive alternative, offering a quicker turnaround for custom designs without the cumbersome setup required by screen printing. The adaptability of DTF allows for efficient adjustments, making it ideal for businesses that require flexibility in their printing solutions.

Additionally, the quality of prints obtained through DTF is often superior to that achieved via screen printing. While screen printing is limited in color gradation and design complexity, DTF can accurately reproduce intricate designs with a rich color palette. This makes DTF particularly attractive for unique, individual pieces or low-volume orders where detail and vibrancy are essential.

Benefits of Using DTF Transfers over Heat Transfer Vinyl

Heat Transfer Vinyl (HTV) is a user-friendly option popular among DIY enthusiasts for its straightforward application process. However, when it comes to capturing intricate details and achieving a wide range of colors, HTV falls short compared to DTF transfers. Users often struggle with designs that require fine lines or detailed graphics, which can be easily printed with DTF technology. The overall vibrancy and precision of DTF prints give it a competitive edge, especially for designers seeking top-notch results in their work.

Moreover, DTF printing allows for a broader spectrum of fabric compatibility compared to HTV. While HTV generally works best with cotton and tends to limit its application to specific materials, DTF can be effectively applied to a range of textiles, including polyester and mixed blends. This versatility encourages businesses to reach a wider audience and fulfill diverse customer needs—something that can be crucial in today’s competitive environment.

Direct to Garment Printing vs. DTF Transfers

Direct to Garment (DTG) printing has been celebrated for its ability to create complex, colorful designs with high fidelity. However, it requires a series of preparation steps, such as fabric pre-treatment, which can add time and cost to the process. In contrast, DTF transfers streamline the workflow by eliminating the need for pre-treatments, allowing users to jump straight to printing and transferring. This efficiency is particularly important for small business owners looking to minimize turnaround times and maximize profitability.

Another aspect where DTF shines is its application across various fabric types. While DTG is often limited to cotton and other similar materials, DTF’s adaptability means it can be utilized on more diverse ranges, from light to dark fabrics, including blends that might otherwise pose challenges for DTG technology. This unique capability enables businesses to offer a wider array of products, making DTF a more versatile and appealing printing option.

Challenges of Implementing DTF Transfers

While DTF printing brings numerous advantages, potential users must also consider the associated challenges. One immediate concern is the initial investment required for specialized equipment, including DTF printers and heat presses. This upfront cost can be a significant barrier for small businesses or hobbyists who might be hesitant to invest heavily without first confirming the technology’s suitability for their needs. Conducting thorough market research and cost analysis is essential before making this leap.

Furthermore, the DTF process incorporates additional steps, such as the application of adhesive powder and subsequent curing of the film. Such extra steps introduce complexity into the workflow, contrasting with simpler methods like HTV. Businesses considering DTF must weigh these factors against the benefits, ensuring they are prepared for the learning curve and operational changes that may accompany the adoption of this innovative printing method.

Future Trends in DTF Printing Technology

The landscape of DTF printing is rapidly evolving, marked by continuous advancements aimed at enhancing the printing process. Recently, technological developments have focused on streamlining procedures to further reduce turnaround times and improve print quality. These innovations include enhanced inks and improved adhesive formulations, which are designed to deliver superior durability and washability for fabric prints. Such enhancements are paving the way for DTF to become a standard in the print industry.

In addition to technological improvements, the increasing popularity of custom printing in the e-commerce sphere is driving demand for DTF transfers. As more crafters and small business owners seek to differentiate their offerings with unique, high-quality printed products, DTF printing provides an accessible avenue to meet these market demands. This growing trend illustrates DTF’s potential to cement its position as a dominant force in the competitive printing marketplace, providing viable solutions for both small operations and larger manufacturing needs.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film which is then transferred onto fabric using a heat press. This method allows for high-quality prints with vibrant colors, offering a more straightforward process than methods like Direct to Garment (DTG) printing, as it eliminates the need for pre-treatment.

How do DTF Transfers compare to Direct to Garment printing?

DTF transfers offer several advantages over Direct to Garment (DTG) printing. While DTG produces high-quality prints, it requires pre-treatment of fabrics and is often restricted to certain materials. In contrast, DTF can print on a variety of fabrics without pre-treatment, making it a versatile and efficient choice for custom designs.

Are DTF Transfers better than Heat Transfer Vinyl (HTV)?

DTF transfers are generally considered superior to Heat Transfer Vinyl (HTV) for detailed and vibrant designs. While HTV is user-friendly for DIY projects, it often lacks the precision and color range that DTF printing provides, making DTF a preferred option for intricate designs and competitive markets.

What are the main advantages of using DTF Transfers for printing?

The main advantages of DTF transfers include their ability to produce high-quality prints with vibrant colors, versatility across various fabric types, and the elimination of pre-treatment requirements. These factors make DTF printing an appealing choice for small businesses and custom garment shops.

What are the drawbacks of DTF Transfers compared to other printing methods?

While DTF transfers offer many benefits, they do come with drawbacks such as the initial equipment investment for specialized printers and heat presses. Additionally, the process involves more steps, including the application of adhesive powder and curing, which can make it more complex compared to simpler methods like screen printing or HTV.

Can DTF Transfers be used for all types of fabrics?

Yes, DTF transfers are versatile and can be used on a variety of fabric types, including cotton, polyester, and blends. This adaptability allows businesses to create custom garments and promotional materials that cater to diverse customer needs, making DTF printing a popular choice.

| Key Point | Details |

|---|---|

| DTF Transfers Definition | Printing designs on film for transfer to fabric using heat and pressure. |

| Quality Prints | Produces vibrant colors and sharp details, ideal for complex designs. |

| Versatility | Compatible with various materials like cotton and polyester, catering to diverse demands. |

| No Pre-treatment | Simplifies the process by eliminating the need for fabric pre-treatment, saving time and costs. |

| Compared to Screen Printing | Allows quick design changes and is better for small runs than screen printing’s bulk adjustment. |

| Compared to HTV | DTF excels in detail and color vibrancy, making it superior for intricate designs. |

| Compared to DTG | DTF is more efficient and versatile with fabric types, lacking the pre-treatment requirement of DTG. |

| Drawbacks | Involves upfront equipment costs and additional steps like adhesive application and curing. |

| Market Trends | Advancements in technology and services make DTF transfers increasingly accessible and popular. |

Summary

DTF Transfers are revolutionizing the printing industry with their unmatched quality and flexibility. By understanding the advantages of DTF compared to traditional methods like screen printing, HTV, and DTG, individuals and businesses can effectively choose the printing technique that best suits their needs. DTF printing simplifies the process without compromising on the vibrant outcomes, making it an appealing choice for various applications, from custom garments to promotional materials. As the landscape evolves, keeping an eye on trends and innovations in DTF transfers will ensure staying competitive and meeting the demands of modern consumers.