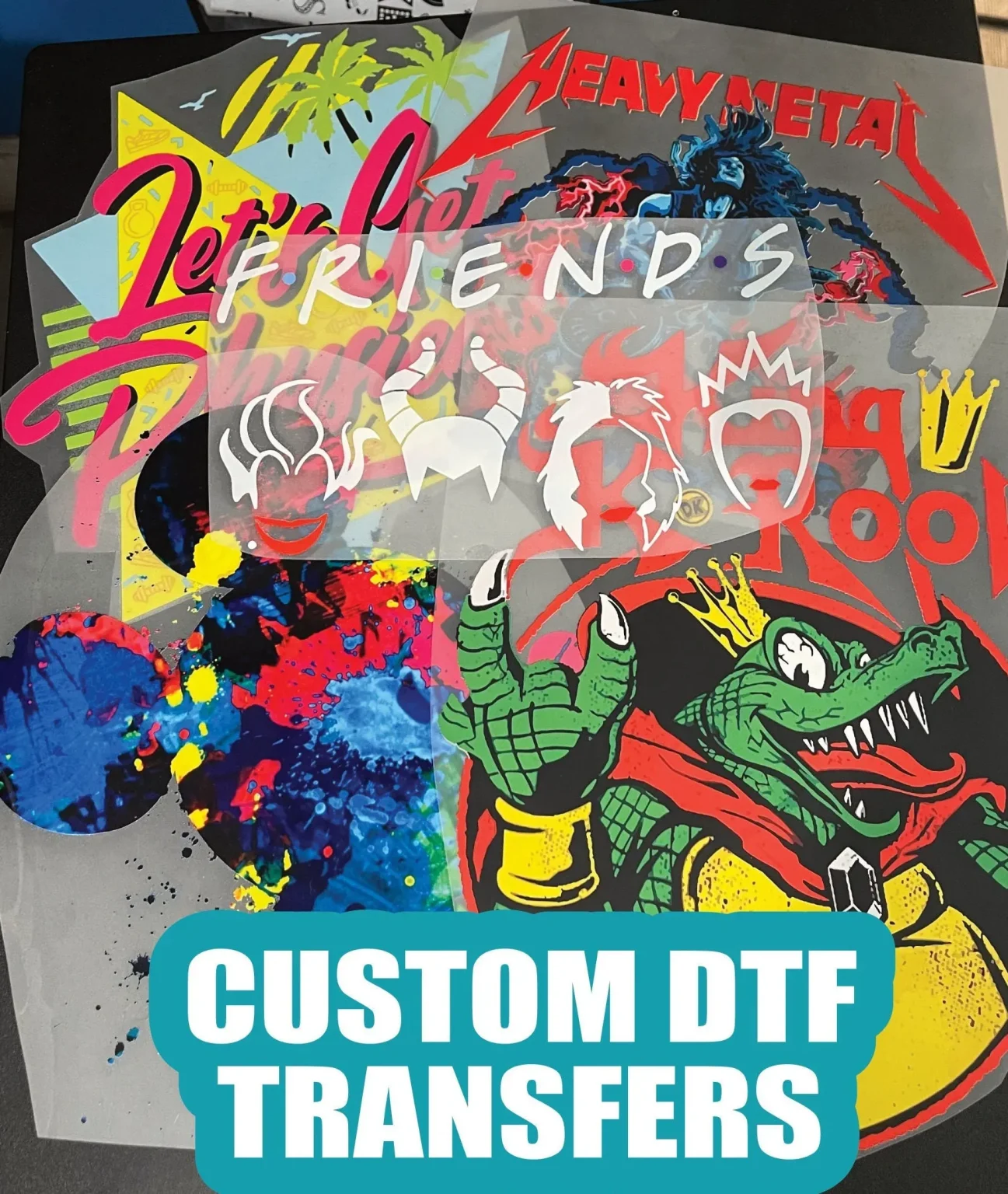

DTF transfers, or Direct-to-Film transfers, have emerged as a powerful tool for artists and businesses seeking to create vibrant, high-quality designs on fabric. This innovative printing method allows for an incredibly detailed output that can be applied to a wide range of materials, revolutionizing how custom DTF prints are made. In this tutorial, we will guide you through a step-by-step DTF guide to ensure your projects achieve the best results. From selecting materials to perfecting your technique, understanding how to make DTF transfers will unlock new creative possibilities. With best practices for DTF printing in hand, you’ll be well-equipped to impress with your custom creations!

When we talk about DTF printing, we’re referring to a cutting-edge method that promises superior quality and versatility for fabric designs. Known by various names, including direct-to-film printing, this approach enables the application of intricate designs on garments with ease and precision. Whether you’re looking to craft custom designs for personal use or small business ventures, mastering this art opens up a world of opportunities. In this detailed guide, we’ll explore the essential tools and steps involved in creating stunning DTF transfers. Get ready to discover a method that not only simplifies the printing process but also enhances your creative output!

Understanding the DTF Printing Process

DTF printing stands for Direct-to-Film printing, a revolutionary technique allowing users to create exceptional quality prints on various materials. This process involves several critical steps, including design creation, printing on special transfer film, and the application of adhesive powder to bind the ink effectively. Unlike traditional methods, DTF printing allows for a higher level of detail and a broader range of colors, making it the preferred choice for many businesses and crafters looking to create custom apparel.

The unique aspect of DTF printing lies in its method of transferring designs from film to fabric. By using state-of-the-art printers that support eco-solvent or water-based inks, users can achieve vibrant, long-lasting images. This technique not only caters to elaborate graphics with numerous colors but also ensures durability despite repeated washing. Understanding how DTF works is essential to mastering the craft, and it’s the first step towards creating stunning designs.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing technique where designs are printed onto a specialized film, coated with adhesive powder, and then heat pressed onto fabrics. This method allows for vibrant, detailed, and durable designs that can withstand multiple washes. It differs from traditional screen printing, making it ideal for custom DTF prints with complex colors and designs.

What materials do I need for making DTF transfers?

To make DTF transfers, you’ll need a DTF printer, DTF transfer film, adhesive powder, a heat press, design software (like Adobe Illustrator), and garments to transfer your designs onto. Choosing quality materials ensures the best results in your DTF printing projects.

Can I create custom DTF prints at home?

Yes, you can create custom DTF prints at home using a DTF printer and the right materials. By following a step-by-step DTF guide, you can produce high-quality transfers that allow personalization on various fabrics, making it perfect for DIY projects and small businesses.

What are the best practices for DTF printing?

Best practices for DTF printing include using high-quality materials, ensuring proper printer settings for the media, and adhering to recommended temperatures and times while heat pressing. Additionally, experimenting with different designs can enhance creativity and improve your DTF transfer results.

How do I make DTF transfers with intricate designs?

To make DTF transfers with intricate designs, use a design software to create detailed artwork at a high resolution (300 DPI is recommended). Print the design in mirror image on DTF transfer film, ensuring careful application of adhesive powder after printing, followed by precise heat pressing to ensure all details adhere correctly.

What should I do if my DTF transfer design peels off after washing?

If your DTF transfer design is peeling off after washing, it may indicate issues with adhesive application or curing. To prevent this, ensure the adhesive powder is evenly applied while the ink is still wet and cure it properly using the recommended heat and time settings. Testing the transfer’s durability through a wash test before finalizing your process can also help.

| Key Point | Details |

|---|---|

| What is DTF Printing? | DTF printing involves printing an image on special film, applying adhesive powder, then using heat to transfer it onto garments, resulting in vibrant, detailed prints. |

| Tools and Materials Needed | DTF printer, DTF transfer film, adhesive powder, heat press, design software, computer, and garments are essential for creating DTF transfers. |

| Step 1: Create Your Design | Use design software to create high-resolution artwork suitable for DTF printing. Focus on vibrant colors and intricate details. |

| Step 2: Print Your Design | Load the film into the printer and print in mirror image format; ensure the matte side is used for printing. |

| Step 3: Apply Adhesive Powder | Immediately sprinkle adhesive powder onto the wet ink to ensure it adheres properly. |

| Step 4: Cure the Adhesive | Cure the film using a heat press at 160-180 °C for 30-60 seconds to set the adhesive properly. |

| Step 5: Position the Transfer | Prepare the garment by ensuring it is clean and wrinkle-free, then place the transfer accordingly. |

| Step 6: Heat Transfer the Design | Apply heat and pressure using the heat press for 15-20 seconds at appropriate settings for the fabric. |

| Step 7: Peel the Film | Carefully peel the film away once cooled; reapply heat if any part of the design lifts. |

| Step 8: Test Your Transfer | Conduct a wash test to ensure the transfer’s durability and assess the quality of the process. |

Summary

DTF transfers have transformed the world of printing, offering a unique method to create vibrant and detailed designs. By following this systematic approach, anyone can navigate the process of DTF transfers, ensuring professional results while working from home. The ability to render complex images and colorful graphics onto fabric opens a new level of creativity, making it ideal for both personal projects and commercial endeavors. Engaging in DTF printing not only enhances artistic expression but also leads to high-quality wearable art.