DTF transfers, or Direct to Film transfers, are transforming the landscape of custom printing, captivating both novices and skilled graphic designers alike. This cutting-edge technique empowers users to produce vivid, high-quality designs that can be easily transferred onto a variety of fabrics, making it ideal for personalized merchandise and unique fashion statements. With the rise of DTF printing, enthusiasts are discovering the advantages of vibrant colors, impressive durability, and versatility in their creative projects. In this article, we delve into essential tips and techniques to help beginners gain a solid footing in the world of custom transfer printing. Whether you’re comparing DTF vs. sublimation or seeking beginner tips for DTF, we’ve got you covered with insights that will boost your confidence and creativity.

Direct to Film printing, often referred to as DTF technology, is rapidly emerging as a preferred choice among makers and designers for its efficiency and capability to deliver eye-catching results. This modern custom transfer process enables creators to seamlessly print intricate designs onto specialized films, which are then applied to fabrics using heat. By exploring the various DTF techniques, users can unlock the potential of fabric printing with stunning, durable outcomes. In this piece, we will introduce you to the fundamentals of DTF transfers, shedding light on significant advancements and helpful beginner tips that will enrich your printing journey. Mastering the art of DTF not only enhances your project outcomes but also elevates your artistic expression.

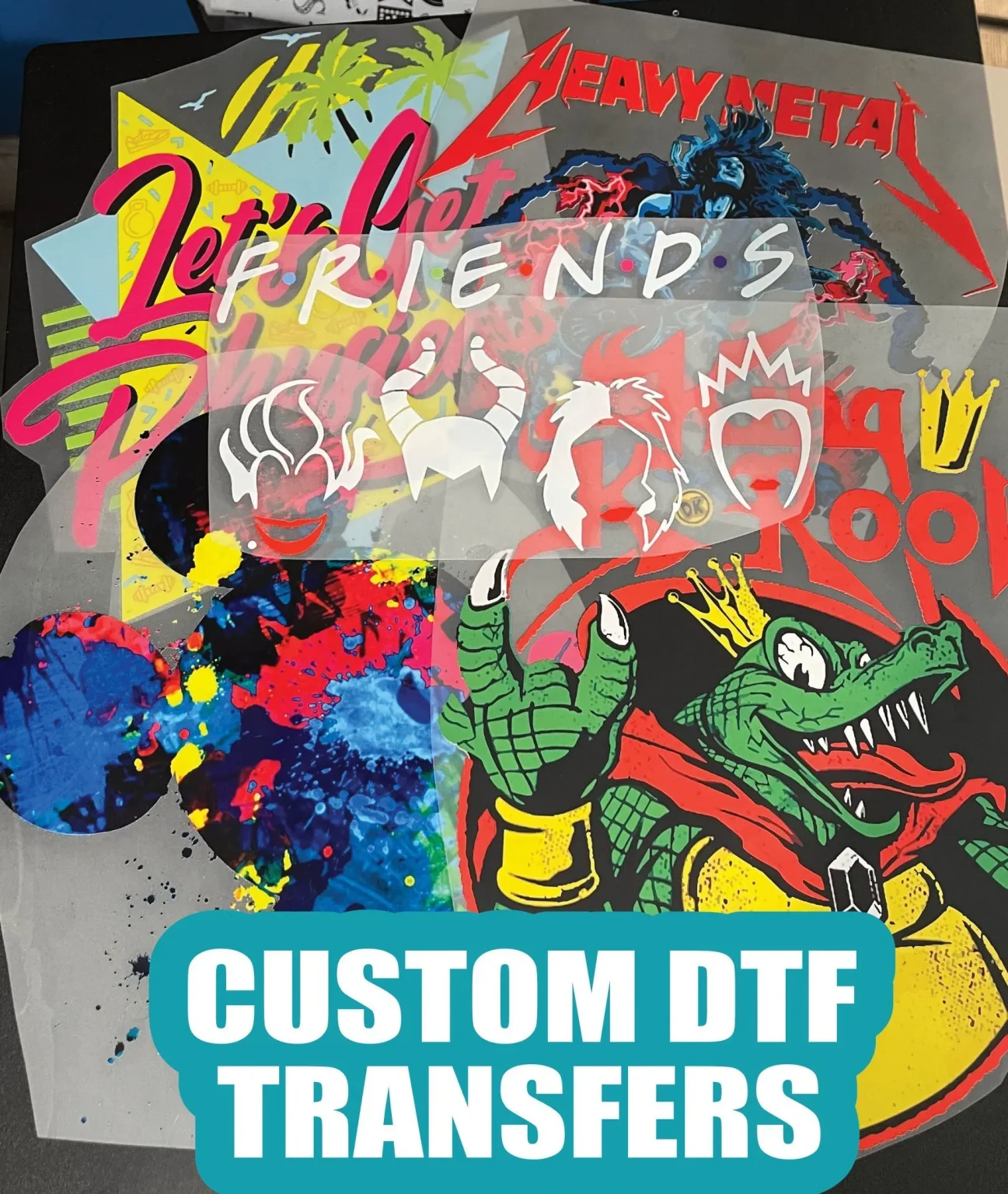

The Appeal of DTF Transfers in Custom Printing

DTF transfers have become a go-to method for many custom print enthusiasts due to their unique advantages. One of the key appeals is the ability to achieve vibrant colors that translate beautifully onto various fabric types. Unlike traditional methods, DTF printing allows for an array of colors without sacrificing quality, resulting in striking designs that stand out. This is particularly beneficial for those looking to create eye-catching apparel or promotional materials that demand attention.

Additionally, DTF transfers offer durability that outperforms many other printing techniques. Once applied, these transfers are resistant to fading and can withstand multiple washes, making them perfect for everyday wear. This durability ensures that the designs remain as fresh and vibrant as the day they were printed, providing excellent value for both the creator and the end user. This aspect of DTF printing attracts not just hobbyists, but also professionals and businesses looking to deliver high-quality products.

Recent Trends and Innovations in DTF Technique

The world of DTF printing is evolving rapidly, with new innovations continuously enhancing the process. Recent developments, such as the introduction of custom DTF printing services, have made it easier for beginners to get started without significant investment in equipment. This service allows users to send their designs and receive high-quality prints tailored to their needs, thus lowering the barrier to entry for those unfamiliar with the process.

Moreover, advancements in DTF technology have simplified the overall workflow. Users can now access better inks and versatile DTF films that improve the quality and ease of the transfer process. As these technologies become available, the community sees an influx of creative ideas, encouraging more individuals to explore the possibilities of DTF printing. Staying updated on these trends can help beginners make informed decisions and harness the potential of DTF in their projects.

Understanding DTF vs. Other Printing Methods

When diving into the world of custom printing, understanding the differences between DTF and other methods like sublimation is crucial. DTF printing excels in scenarios where vibrant, full-color designs are necessary without gaps between colors, whereas sublimation typically requires specific fabric types and may limit design options. This distinction helps beginners choose the right method based on their project requirements and desired outcomes.

Furthermore, DTF offers more versatility regarding fabric compatibility, allowing for successful transfers on cotton, polyester, and blends. This wide range of fabric options narrows the selection of materials that can be used with sublimation printing. Thus, for those who want to experiment with different fabrics and designs, DTF becomes the more favorable option, offering superior flexibility in customization.

Essential Equipment for Successful DTF Printing

To embark on a DTF printing journey, investing in the right equipment is essential. It begins with selecting a reliable DTF printer designed specifically for the technique. It’s crucial to do thorough research to choose a model that balances quality and affordability while meeting the needs of hobbyists or professional printers alike.

In addition to a good printer, a high-quality heat press is vital for achieving clean and successful transfers. Look for models that allow precise adjustments in temperature and pressure settings, as these factors significantly influence the transfer quality. Pairing a reliable printer with an effective heat press forms the backbone of any FTD printing setup, ensuring consistent results and creativity.

Preparing Your Designs for DTF Success

Successful DTF printing begins with careful preparation of your designs. Utilizing design software that aligns with DTF specifications is crucial. Ensuring your designs are set to the correct resolution and color mode can dramatically improve the final outcomes of your transfers, allowing for sharper and more vibrant prints.

Additionally, performing test prints on scrap materials is a practical tip that can save time and resources. This allows you to fine-tune the heat press settings to find the optimal combination of time, temperature, and pressure for your specific films and inks. Preparing in this way helps minimize the risk of errors during the actual transfer process.

Best Practices for Caring for DTF Transfers

Once your DTF transfers are complete, it’s important to follow specific care instructions to maintain their quality. Washing printed fabrics in cold water and avoiding harsh detergents can significantly extend the life of your prints, ensuring they remain vibrant after many washes. Proper care doesn’t only protect your investment but also upholds the integrity of your designs.

Furthermore, proper storage of printed fabrics can prolong their lifespans. Keeping them in cool, dry places away from direct sunlight helps resist fading and deterioration. By following these best practices, users can enjoy their DTF creations for the long term, showcasing the beauty of their hard work and creativity.

Frequently Asked Questions

What is DTF printing and how does it relate to DTF transfers?

DTF printing, or Direct to Film printing, is a technique where designs are printed onto a special film, which is then transferred onto fabric using a heat press. DTF transfers are created through this process, allowing for vibrant, durable prints on various fabrics. This method is increasingly popular among crafters due to its capable results and versatility.

What are the advantages of using DTF transfers for custom designs?

DTF transfers offer several advantages, including vibrant colors, high durability against washes, and versatility across different fabric types like cotton and polyester. These features make DTF printing an ideal choice for custom designs, ensuring that your creations look great and last longer.

How does DTF printing compare to sublimation printing in terms of results?

When comparing DTF vs sublimation printing, DTF is preferred for full-color designs without gaps, producing durable transfers that hold up during washing. Sublimation is limited to polyester fabrics, while DTF can be used on a wider variety of materials, making it a more versatile choice for custom transfer printing.

What essential equipment do I need to start with DTF transfers?

To successfully start DTF transfers, you need a DTF printer designed for this process, a reliable heat press, DTF film for transfers, and specialized inks compatible with DTF printing. Having the right equipment is crucial for achieving high-quality results.

What beginner tips can help me succeed with DTF printing?

Beginners can benefit from several tips, such as using compatible design software, performing test prints to adjust heat press settings, and watching online tutorials. Joining DTF communities can also provide valuable insights and support from experienced printers.

What post-transfer care should I follow for DTF printed fabrics?

After completing DTF transfers, it’s important to follow specific care instructions: wash printed fabrics in cold water, avoid bleach and harsh detergents, and store them in a cool, dry place away from direct sunlight. These practices help maintain the vibrancy and longevity of your prints.

| Key Aspects of DTF Transfers | |

|---|---|

| Technique | Description |

| DTF Printing Process | Print design on specialized film, then transfer to fabric using heat press for vibrant colors and durability. |

| Advantages | 1. Vibrant Colors: High-quality prints that resist fading. 2. Durability: Transfers withstand multiple washes. 3. Versatility: Works on various fabric types. |

| Essential Equipment | DTF printer, heat press, DTF film, and specialized inks are necessary to start DTF printing. |

| Design Preparation | Select compatible design software and perform test prints to fine-tune heat press settings. |

| Transfer Techniques | Control temperature, apply even pressure, and peel the film carefully to ensure quality transfers. |

| Post-Transfer Care | Follow washing instructions and store fabrics properly to maintain print quality. |

| Tips for Beginners | Engage with online communities, watch video tutorials, and experiment with designs and techniques. |

Summary

DTF Transfers have emerged as a revolutionary technique for achieving vibrant, high-quality fabric designs. By utilizing the DTF printing process, users can create durable and detailed prints that withstand the rigors of daily use and washing. This method not only allows for incredible versatility across various fabrics but also caters perfectly to beginners with its accessibility and ease of use. With the right tools and preparation, anyone can dive into the world of DTF transfers and explore their creative potential. From understanding the necessary equipment to mastering transfer techniques, new artists will find a wealth of resources to support their journey into this exciting craft.