In the competitive landscape of custom apparel, DTF transfers, or Direct to Film transfers, have emerged as a game-changing printing technology. This innovative method enables designers to produce high-quality prints with vibrant colors and intricate details that appeal to today’s discerning consumers. With its versatility across various fabric types and a streamlined application process, DTF transfers allow businesses to efficiently meet the diverse needs of their customers. Additionally, the use of eco-friendly inks aligns with the growing demand for sustainable practices in the fashion industry, making DTF a responsible choice for eco-conscious entrepreneurs. In this article, we delve into the top benefits of DTF transfers and how they can elevate your custom apparel business to new heights.

In the realm of custom clothing, the advent of Direct to Film transfers is revolutionizing traditional printing methods. Also referred to as DTF printing, this innovative approach facilitates seamless design transfers, delivering visually stunning results on a wide array of fabrics. Business owners in the custom apparel sector are increasingly recognizing the advantages of this technology, from its cost-effectiveness to its efficiency in production. By utilizing advanced printing technologies and eco-friendly inks, DTF transfers not only enhance product quality but also cater to the rising trend of sustainability in fashion. As we explore the myriad benefits of this dynamic printing method, it’s clear that embracing DTF can significantly boost the appeal and operational success of your apparel offerings.

Understanding DTF Transfers in Custom Apparel

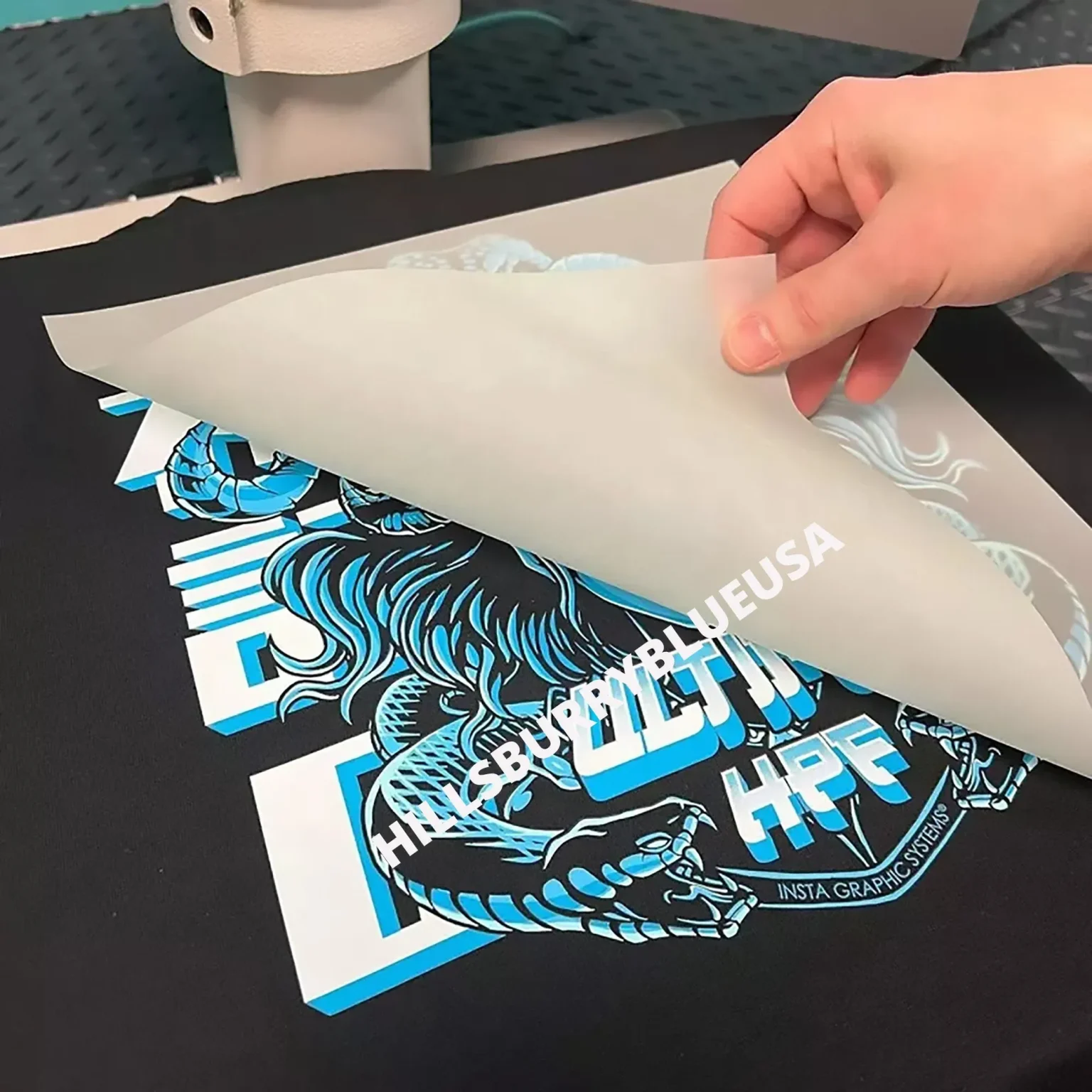

Direct to Film (DTF) transfers have emerged as a revolutionary technique in the custom apparel space, allowing for the simple and effective transfer of designs onto various fabrics. This method involves printing a design onto a special film, followed by applying that film to a garment with heat and pressure. The versatility of DTF transfers means they can be adapted to different types of materials like cotton, polyester, and even blends, making it an appealing option for businesses that aim to provide a diverse range of products. Businesses adopting DTF typically find themselves empowered to meet consumer demands more effectively, as they are no longer confined to limited fabric choices.

Moreover, understanding DTF transfers in the context of custom apparel requires recognizing their impact on the creative flexibility of designers and entrepreneurs alike. This printing technology supports intricate designs and vibrant color schemes, which are essential in a market where consumers seek unique and personalized apparel. Effective utilization of DTF transfers can distinguish a brand in a competitive market, emphasizing the capability of producing quality prints that meet or exceed customer expectations.

The Advantages of DTF Transfers for Custom Apparel

DTF transfers present several key advantages over traditional printing methods, such as Direct to Garment (DTG) or screen printing. One primary benefit is the remarkable reduction in setup costs and time. When using DTF, businesses can produce smaller batches without incurring hefty setup fees, thereby catering to custom orders more efficiently. This feature is particularly beneficial for startups or small businesses that may have tight budgets yet aim to maintain high standards for quality. With DTF, the production process is simplified, which ensures that even small-scale orders are feasible without compromising on quality or efficiency.

Furthermore, the high-quality prints produced by DTF technology can stand as a testament to a brand’s commitment to excellence. The vibrant colors and precise details achievable with DTF transfers rival those of more established methods, making it an attractive option for entrepreneurs looking to make their mark in the custom apparel industry. The ability to produce eye-catching designs not only fulfills the creative demands of consumers but also enhances marketability, setting the stage for increased sales and customer loyalty.

Cost-Effectiveness of DTF Printing for Small Businesses

One of the most significant advantages of DTF transfers is their cost-effectiveness, particularly for small and medium-sized custom apparel businesses. Unlike traditional printing techniques that often require substantial setup costs, DTF technology allows for lower operational expenses. This means that businesses can maintain a healthy profit margin even when dealing with limited production runs. Since DTF printing requires less material for setup and can be completed with standard modified printers, entrepreneurs can invest less upfront while still delivering high-quality products to customers.

This economical approach to printing not only aids in achieving better financial outcomes but also makes it possible for businesses to offer competitive pricing to their customers. Many entrepreneurs are finding that they can provide premium products at competitive rates, which is vital in attracting and retaining a loyal consumer base in the saturated custom apparel market. By leveraging DTF transfers, businesses can maximize profitability while delivering exceptional value and quality.

Eco-Friendly Inks in DTF Transfers

Sustainability is increasingly vital in today’s consumer landscape, and DTF transfers align well with eco-friendly practices. The majority of inks used in DTF printing are water-based, significantly reducing the environmental impact compared to the solvent-based inks typically found in traditional printing methods. By adopting eco-friendly inks, businesses not only fulfill their corporate social responsibilities but also appeal to a growing demographic of environmentally conscious customers. This practice positions companies as modern and responsible, aligning their products with consumers’ values.

Moreover, using water-based inks in DTF transfers allows companies to promote their commitment to sustainability effectively. With consumers becoming more selective about their purchasing decisions, showcasing eco-friendly practices can lead to increased brand loyalty and customer engagement. Businesses that prioritize environmentally friendly production techniques, such as DTF printing, can create a unique selling proposition that resonates deeply with consumers, further solidifying their presence in the competitive custom apparel market.

Simplicity and Speed of DTF Transfer Application

In today’s fast-paced fashion environment, efficiency is of utmost importance. DTF transfers are celebrated for their straightforward application process, which allows businesses to expedite production timelines significantly. The ability to apply designs through a single-step transfer process reduces the time spent on production, helping businesses keep pace with rapidly changing fashion trends and customer demands. This increased efficiency is particularly beneficial to companies aiming to build a reputation for reliability in the marketplace.

As businesses transition to DTF technology, many report shorter turnaround times, which enhances overall customer satisfaction. By minimizing production bottlenecks and maintaining a steady flow of high-quality products, companies can boost their operational efficiency. The simplicity of applying DTF transfers empowers team members to focus on more critical aspects of the business, such as marketing and customer service, rather than getting bogged down by complicated printing processes.

Breaking Barriers with DTF in Startups

One of the greatest fears for startups in the custom apparel industry is the high cost of entry related to printing equipment. However, DTF printing presents a solution by removing the requirement for specialized, expensive machinery. Most standard printers can be modified for DTF use, allowing newcomers to enter the market without the financial burden typically associated with custom printing. This accessibility fosters creativity and innovation among up-and-coming entrepreneurs, leveling the playing field in a competitive industry.

As a result, more startups are embracing DTF technology to bring their unique visions to life. With DTF, budding businesses can experiment with various styles and designs without significant upfront investment. This adaptability helps new players cultivate a loyal customer base and establish brand recognition more swiftly by producing desirable and high-quality custom apparel. Ultimately, DTF transfers are democratizing the printing process, making it more feasible for passionate entrepreneurs to thrive.

Frequently Asked Questions

What are the advantages of using DTF transfers in custom apparel printing?

DTF transfers offer numerous advantages for custom apparel printing, including versatility on various fabrics, high-quality vibrant prints, cost-effectiveness for small to medium runs, speed and simplicity of application, and the availability of eco-friendly inks. These benefits allow businesses to meet diverse customer needs efficiently while maintaining high standards of quality.

How do DTF transfers compare to traditional printing methods for custom apparel?

DTF transfers differentiate themselves from traditional printing methods like screen printing and DTG by providing similar high-quality prints and vibrant colors while being more cost-effective and easier to apply. This makes DTF a preferred choice for businesses looking for efficiency and flexibility in custom apparel production.

Can DTF transfers be applied to different fabric types?

Yes, one of the significant benefits of DTF transfers is their versatility; they can be applied to a wide range of fabric types, including cotton, polyester, and blended materials. This flexibility enables custom apparel businesses to expand their product offerings without being limited by fabric type.

Are DTF transfers a sustainable printing option for custom apparel?

DTF transfers are regarded as an eco-friendly option because many DTF inks are water-based, contrasting with traditional solvent-based inks. By using DTF technology, custom apparel businesses can align with consumer demand for sustainable products while minimizing their environmental impact.

Is there special equipment required for DTF transfers in custom apparel?

No, DTF transfers do not require specialized high-cost equipment. Standard printers can often be modified for DTF use, lowering the barrier to entry for startups in the custom apparel industry and making it an accessible printing technology.

What makes DTF printing technology cost-effective for small businesses?

DTF printing technology is cost-effective for small businesses because it involves lower setup times and material costs compared to traditional methods. This enables businesses to produce high-quality prints without incurring extensive overhead, allowing them to maximize profits even on smaller print runs.

| Key Benefits | Description |

|---|---|

| Versatility in Fabrics | DTF transfers can be applied to various fabrics like cotton, polyester, and blends, allowing businesses to cater to a diverse customer base. |

| High-Quality Prints | DTF technology offers vibrant colors and high-resolution images, comparable to traditional methods, making it popular among apparel decorators. |

| Cost-Effectiveness | DTF transfers reduce setup time and material costs, providing significant savings for small to medium-sized print runs. |

| Simplicity and Speed of Application | The transfer process is easy and rapid, significantly decreasing turnaround times and enhancing production efficiency. |

| Eco-Friendly Options | Many DTF inks are water-based, making them a more sustainable choice compared to solvent-based inks. |

| No Need for Special Equipment | DTF does not require expensive machinery; standard printers can be modified for use, lowering the barrier for startups. |

Summary

DTF transfers offer a transformative solution for your custom apparel business, combining efficiency, quality, and affordability. This innovative printing method not only caters to a wide array of fabrics but also delivers high-resolution prints that resonate with consumers. By reducing costs and simplifying the application process, DTF transfers allow businesses to operate more effectively while appealing to eco-conscious customers with their sustainable ink options. As you navigate the growing custom apparel market, incorporating DTF transfers into your production workflow can be key to standing out and thriving in a competitive landscape.