In the dynamic world of printing technology, DTF transfers have emerged as a powerful alternative, challenging traditional methods like screen printing and direct-to-garment (DTG) printing. With their ability to deliver vibrant designs and remarkable print quality, DTF printing offers businesses an innovative solution that balances efficiency and creativity. This article will delve into the advantages and considerations of DTF transfers compared to more established printing techniques, shedding light on their cost-effectiveness and production capabilities. As businesses strive to meet the evolving demands of customers, understanding the nuances between DTF and traditional printing becomes crucial in making informed choices. Discover how DTF transfers can redefine your printing strategy and propel your business forward in a competitive market.

When exploring fabric printing options, many professionals encounter terms like Direct-to-Film (DTF) transfers, screen printing, and direct-to-garment (DTG) approaches. These methods present unique advantages and challenges that can influence a business’s printing strategy. DTF technology stands out for its ability to create high-quality images on various fabric types while ensuring vibrant color reproduction and durability. On the other hand, traditional approaches, such as screen printing, rely on time-tested techniques that have dominated the market for years. Understanding the distinctions between DTF and its predecessor methods is essential for anyone looking to enhance their printing capabilities.

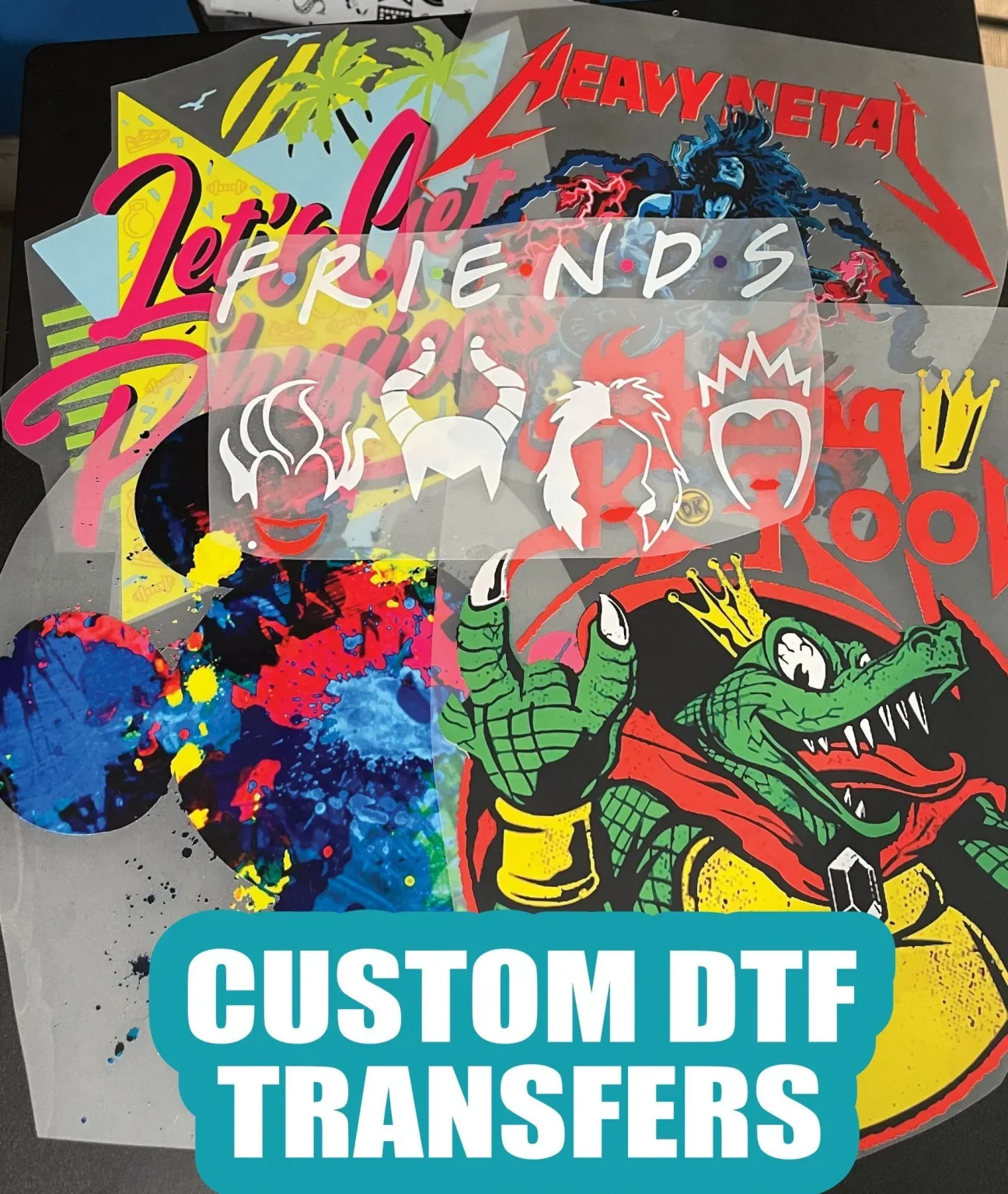

The Fundamentals of DTF Transfers and Traditional Printing

DTF transfers, or Direct-to-Film printing, is an emerging technology that revolutionizes how designs are applied to fabrics. Unlike traditional methods, DTF printing involves printing directly onto a specialized film, which is then heat-pressed onto the target garment. This approach allows for a high level of detail and color accuracy, making it a favorite among businesses seeking to create vibrant, eye-catching apparel. The versatility of DTF prints means they can be used on a variety of textiles, including cotton, polyester, and blends, easily accommodating various fabric types.

In contrast, traditional printing techniques, such as screen printing and direct-to-garment (DTG) printing, have been long-standing choices in the industry. Screen printing relies on creating a stencil, and is best suited for designs with fewer colors, while DTG printing uses inkjet technology to directly apply ink onto garments. Both methods deliver unique advantages, but their initial setup costs can be high, especially for small businesses or those focusing on custom orders. Understanding these fundamental differences helps businesses align their choice of printing technology with their operational goals.

Cost Analysis: DTF Transfers vs. Traditional Methods

When evaluating the cost-effectiveness of DTF transfers compared to traditional printing methods, DTF stands out for its lower initial investment. For small businesses or startups, DTF printing eliminates the hefty setup costs required by traditional methods like screen printing. This allows business owners to test various designs and respond quickly to market demands without extensive financial risk. Additionally, DTF technology enables businesses to print at lower volumes without sacrificing quality, making it a sound choice for enterprises operating with limited budgets.

Conversely, while traditional printing methods can be pricey upfront, such as those seen in screen printing due to the need for physical stencils, they often become more cost-efficient at scale. For companies focusing on mass production with repetitive designs, traditional printing can take advantage of economies of scale, ultimately lowering the cost per item. Businesses must carefully analyze their order volume and production needs to determine the most financially viable printing method.

Quality Comparison: DTF Printing vs. Traditional Techniques

Quality Comparison: DTF Printing vs. Traditional Techniques

Quality is paramount in printing, and here DTF transfers often outperform traditional methods. DTF printing produces stunning visual results, capable of vibrant colors and intricate designs across various fabric types. One of the greatest strengths of DTF is its ability to maintain print integrity, even after multiple washes. This level of durability, combined with the flexibility of printing on dark and light fabrics alike, positions DTF as an effective solution for quality-driven businesses.

On the other hand, traditional printing methods have their merit. Screen printing, known for its robust longevity, excels in high-volume jobs where consistency is key. However, DTG printing offers exceptional detail for more complex artwork, making it preferable for niche markets requiring elaborate designs. Understanding the strengths of each method ensures businesses can meet customer demands for quality and creativity.

Production Speed: Enhance Your Workflow with DTF Printing

In today’s fast-paced market, production speed can significantly influence a business’s success. DTF transfers are renowned for their quicker production times, which prove essential for businesses needing to meet stringent deadlines or sudden surges in demand. The ability to quickly transfer designs from film to fabric reduces turnaround times, allowing companies to react rapidly to consumer trends or time-sensitive requests. This agility can give businesses a competitive advantage, especially in industries like fashion or promotional products.

Traditional printing methods, while capable of producing large quantities once set up, often take longer due to the intricate setup process involved, particularly in screen printing. Businesses must balance their production timelines with order volumes, as slower methods may hinder responsiveness in dynamic markets. For enterprises where speed is paramount, DTF printing offers a dynamic solution, proving both efficient and adaptable.

Sustainability in Printing: Choosing Eco-Friendly Options

In the realm of eco-conscious practices, sustainability is an increasingly important consideration in printing technologies. DTF printing uses less water than traditional methods like screen printing, which is a significant advantage. However, the sustainability of DTF largely depends on the type of inks utilized. It’s crucial for businesses to partner with suppliers who adhere to sustainable practices and use eco-friendly materials, thereby reducing their overall environmental impact.

Traditional printing methods also face scrutiny regarding their ecological footprint. Screen printing can require a considerable amount of resources, leading businesses to evaluate their operational practices critically. By adopting environmentally friendly inks and reducing waste during the printing process, companies can enhance their sustainability efforts. In choosing between printing methods, businesses should weigh the environmental implications and pursue practices that align with their corporate social responsibility goals.

Customizability: Tailoring Solutions with DTF Transfers

One of the most compelling advantages of DTF printing lies in its high level of customizability. This technology seamlessly caters to both large production runs and unique small orders, permitting businesses to fulfill diverse customer needs without incurring significant additional costs. The flexibility inherent in DTF printing means that brands can respond swiftly to evolving market trends or customer preferences, ensuring they remain ahead in a competitive landscape.

In contrast, traditional printing methods might be more suited for maintaining consistent branding across larger orders. When producing multiple garments with the same design, the streamlined process of traditional methods can ensure that designs maintain cohesion, reinforcing a brand’s identity. However, for companies focused on personalization and bespoke offerings, DTF printing’s adaptability stands out, allowing for a more innovative approach to meet market demands.

Frequently Asked Questions

What are the main differences between DTF transfers and traditional printing methods?

DTF transfers use a film to apply designs onto fabrics using heat, offering quick production and vibrant colors. Traditional printing methods, such as screen printing and DTG, involve varying techniques for applying inks. DTF is often more versatile and cost-effective for small runs, while traditional methods excel in consistency for bulk orders.

Is DTF printing more cost-effective than traditional printing for small businesses?

Yes, DTF printing typically involves lower initial setup costs, making it attractive for small businesses needing fewer items printed. Unlike traditional printing methods, which can require significant investment upfront, DTF allows for efficient production without straining budgets.

How does the quality of DTF transfers compare with that of traditional printing?

DTF transfers provide vibrant colors and impressive durability across various fabric types. While screen printing is favored for its long-lasting results on certain materials, DTG printing can achieve detailed designs. Overall, DTF often delivers a strong combination of quality and flexibility.

What advantages does DTF printing have in terms of production speed?

DTF printing generally offers faster turnaround times compared to traditional methods, making it ideal for businesses with tight deadlines. While traditional printing can be swift for bulk orders once set up, DTF’s quick production process aligns well with the demands of modern markets.

How do DTF transfers and traditional printing methods differ in their environmental impact?

DTF printing uses less water compared to traditional screen printing, and its eco-friendliness depends on the inks used. Traditional printing methods can also be resource-heavy; thus, businesses should evaluate their practices and materials for sustainability, regardless of the printing technology.

Can DTF printing handle customization better than traditional printing methods?

Absolutely! DTF printing excels in flexibility, allowing for both large orders and unique custom pieces without substantial extras. Traditional printing is typically more suited to consistent branding and larger runs, which might limit customization options.

| Criteria | DTF Transfers | Traditional Printing |

|---|---|---|

| Cost-Effectiveness | Lower initial investment, ideal for small runs. | Higher setup costs, cost-effective for large volume orders. |

| Quality and Durability | Vibrant colors, maintains quality after multiple washes. | Long-lasting prints but less versatile in design. |

| Production Speed | Faster turnaround, suitable for tight deadlines. | Slower setup but quick for bulk orders. |

| Sustainability | Uses less water, but depends on eco-friendly inks. | Resource-intensive, requires careful ink selection. |

| Flexibility and Customization | Accommodates large orders and unique pieces easily. | Best for consistent designs and larger runs. |

| Market Trends | Rising popularity for short-run and customized printing. | Stable in larger production runs with uniform designs. |

Summary

DTF Transfers offer a modern, cost-effective choice for businesses seeking efficient printing solutions. As printing technology continues to evolve, DTF becomes a compelling alternative to traditional printing methods, especially for small to medium-sized businesses focusing on customization and quality. With advantages in speed and versatility, DTF printing meets the demands of a fast-paced market while maintaining excellent durability and eco-friendliness. Therefore, businesses should consider DTF Transfers as a viable option to meet their operational needs and capitalize on market trends.