In the dynamic landscape of fashion and custom apparel, DTF transfers are emerging as a game-changer in the printing process. Utilizing Direct to Film (DTF) printing technology, this method allows for vibrant and intricate designs to be seamlessly transferred onto textiles, revolutionizing how apparel is produced. As sustainability becomes increasingly important to consumers, DTF printing offers a cleaner, more eco-friendly alternative to traditional methods, making it appealing for businesses looking to innovate. With its ability to deliver high-quality outputs across a range of fabrics, DTF transfers are quickly becoming a staple in apparel production. Explore the impact of this technology as it shapes the future of custom apparel, optimizing both efficiency and environmental responsibility.

When discussing DTF transfers, it’s essential to explore various terms that describe the same innovative technology, such as direct to film printing and digital transfer techniques. This modern approach simplifies the artwork application process, making it a popular choice among apparel makers. The rise of sustainable printing practices, coupled with increased demand for custom designs, showcases how direct to film printing is revolutionizing the garment manufacturing industry. Moreover, with its capability to yield superior prints on diverse fabrics, this technology addresses both quality and versatility in apparel production. As we delve deeper into DTF processes, we uncover their significant role in transforming the way brands cater to contemporary consumer needs.

Understanding the Mechanics of DTF Transfers

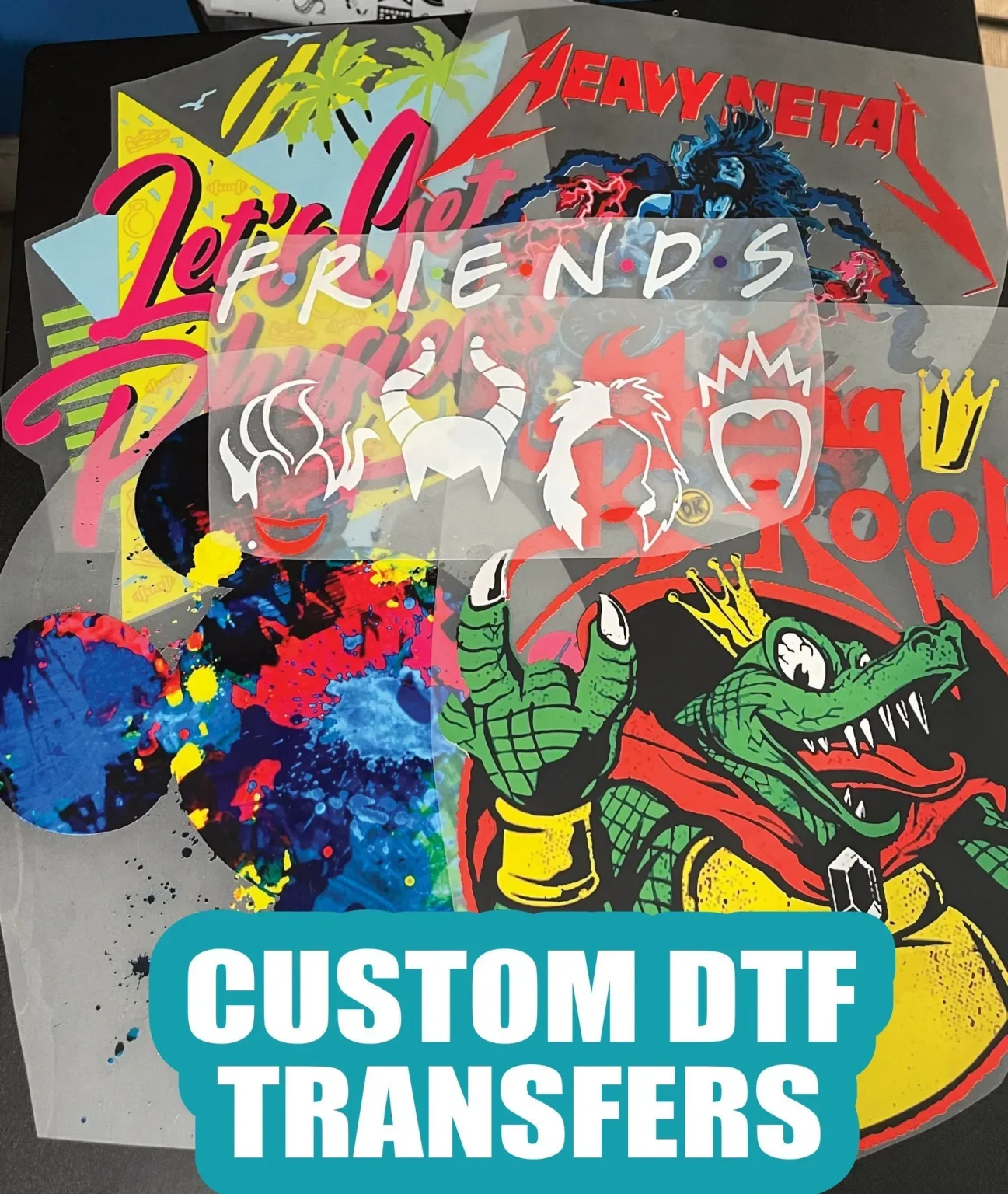

DTF (Direct to Film) transfers are reshaping the custom apparel industry by offering a straightforward and efficient method for printing high-quality designs. In essence, the process involves printing designs onto a special film that can be transferred to fabric using heat. This eliminates the complexities typically associated with traditional screen printing, such as multiple screens and labor-intensive setups. As a result, DTF printing significantly reduces the resources and time needed for apparel production, making it an appealing choice for companies looking to optimize their processes.

Moreover, DTF technology caters to a vast array of fabrics, including both natural and synthetic materials. This compatibility allows custom apparel manufacturers to experiment with various textiles, ultimately broadening their product offerings. With the capacity to produce vibrant colors and sharp details on diverse materials, DTF printing has become a favored method among fashion brands seeking to enhance their product lines.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel production?

DTF Transfers, or Direct to Film printing, is a modern technique that allows designs to be printed directly onto a film and then heat-pressed onto textiles. This process simplifies production, ensuring high-quality prints on custom apparel while catering to various fabric types.

What are the benefits of using DTF printing for custom apparel designs?

DTF printing offers numerous advantages for custom apparel, including vibrant, detailed prints, wide compatibility with fabrics, cost-effectiveness for small runs, and a sustainable approach that reduces waste and environmental impact.

How does DTF printing compare to traditional screen printing in custom apparel?

Unlike traditional screen printing, which requires extensive setup and materials, DTF transfers streamline the process, lower costs, and produce higher-quality designs. This makes DTF ideal for businesses looking for efficiency and flexibility in custom apparel production.

Can DTF Transfers be used on different types of fabrics in custom apparel?

Yes, DTF transfers are compatible with a variety of textiles, including cotton, polyester, and blends. This versatility allows custom apparel manufacturers to cater to diverse consumer preferences.

What makes DTF printing a sustainable choice in the apparel production industry?

DTF printing is considered a more sustainable option due to its reduced material waste and the use of less harmful processes compared to traditional printing methods. This aligns with the growing consumer demand for eco-friendly custom apparel.

What is the future of DTF Transfers in the custom apparel market?

The future of DTF transfers in custom apparel looks promising as technology advances and consumer preferences shift towards personalized products. As more businesses adopt DTF printing, it will continue to play a pivotal role in the evolution of apparel production.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A modern printing technology that transfers designs onto fabrics using a film, streamlining the production process. |

| Advantages of DTF Transfers | 1. High-Quality Prints 2. Wide Fabric Compatibility 3. Cost-Effectiveness 4. Reduced Waste |

| Industry Adoption | Rapid adoption by small and medium-sized enterprises indicates growing popularity and accessibility of DTF technology. |

| Technological Advancements | Improvements in printing machines and inks enhance efficiency, quality, and turnaround times for manufacturers. |

| Market Growth and Consumer Preferences | Shifting consumer preferences towards personalized products boost the efficiency and demand for DTF transfers. |

| Environmental Considerations | DTF printing represents a sustainable alternative to traditional methods, utilizing less harmful processes. |

Summary

DTF Transfers are revolutionizing the custom apparel industry by streamlining the production process while delivering high-quality designs. This innovative printing technology provides several advantages, including versatility across fabric types, cost-effectiveness, and sustainability, which are increasingly important in today’s market. As businesses adapt to changing consumer preferences for personalized apparel, DTF printing stands out as a leading option for manufacturers aiming to meet the evolving demands of the fashion world. Its future looks promising as technological advancements continue to enhance its capabilities, positioning DTF Transfers as a vital player in shaping the landscape of custom clothing production.