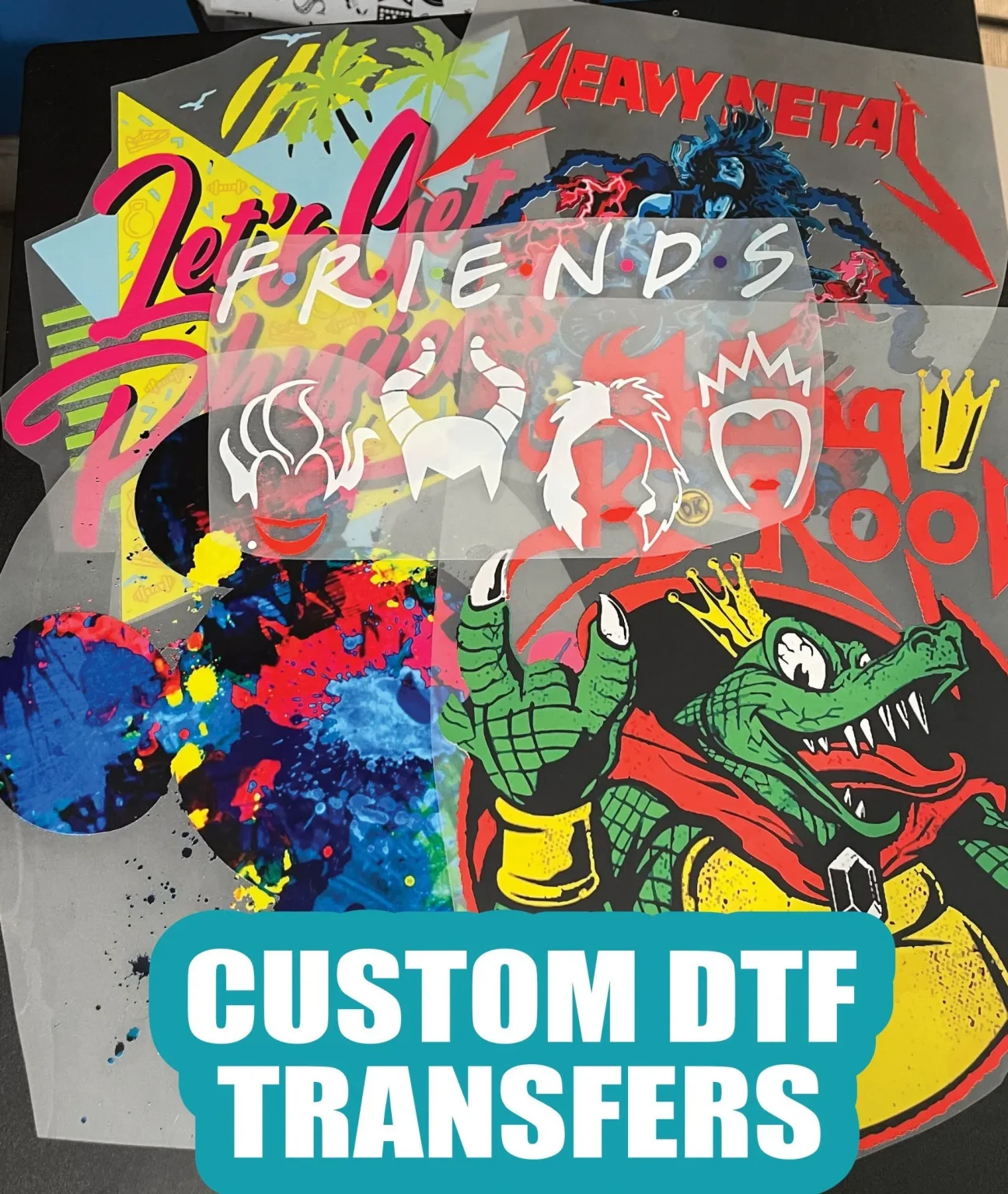

DTF Transfers, or Direct to Film transfers, are swiftly becoming the go-to choice for businesses looking to enhance their custom apparel printing capabilities. This innovative printing process allows for intricate designs and vibrant colors that stand out on a variety of fabrics, making it an appealing option for today’s fashion-forward market. Unlike traditional methods, DTF printing combines efficiency with versatility, enabling production runs of all sizes without the need for complex setup. As companies strive to meet diverse consumer demands, understanding the advantages of DTF transfers becomes essential for staying competitive. In this guide, we’ll explore the DTF printing process in detail, highlighting its many benefits and how it can transform your custom clothing offerings.

In the realm of textile printing, Direct to Film (DFT) printing has emerged as a revolutionary technique for applying designs directly onto fabrics. Often termed as the latest advancement in fabric transfer technology, this method utilizes a specialized film to create stunningly detailed graphics that adhere seamlessly to various materials. This modern approach to custom apparel printing not only simplifies the production process but also enhances the durability of the prints, ensuring they withstand wear and washing. With the rising trend of unique and personalized fashion, exploring the benefits and operational mechanics of this distinct printing method is crucial for any business aiming to thrive in the competitive design landscape. Dive into the fascinating world of DTF solutions and discover how they can elevate your apparel offerings and meet customer preferences like never before.

Understanding the DTF Printing Process

The DTF printing process is a game-changing technology that revolutionizes how designs are printed onto fabrics. This method involves several critical steps that need to be understood to optimize results effectively. Initially, high-quality graphics are printed onto a polyethene terephthalate (PET) film using specialized DTF printers. Following the printing, a heat-sensitive adhesive powder is applied to the wet ink, which is then cured through a heat press to ensure an effective bond. This meticulous combination of printing and powder application guarantees that the inks are vibrantly transferred onto numerous fabric types.

Once the curing process is complete, the film is ready for the final transfer onto the fabric. By placing the film on the desired textile and applying heat and pressure, the adhesive activates, adhering the design securely to the fabric. This method not only facilitates vibrant colors and intricate designs but also allows for printing on a diverse range of materials, from cotton and polyester to more intricate blends. Understanding these procedural nuances is pivotal for anyone looking to engage in DTF printing, as mastering each phase can lead to superior output.

Benefits of DTF Transfers in Custom Apparel

DTF transfers stand out in the custom apparel printing landscape due to their impressive benefits. One of the most significant advantages is their versatility; DTF technology can be applied to various fabric types, including cotton, poly-blend fabrics, and even darker materials without the need for pre-treatment. This flexibility allows businesses to cater to diverse customer needs, whether it’s designing vibrant t-shirts, apparel for events, or personalized merchandise. Furthermore, DTF prints are notably durable, making them resistant to fading, cracking, or peeling over time.

Another compelling advantage of DTF printing is its economical nature, particularly for low-volume productions. Unlike traditional screen printing which often requires large minimum orders, DTF allows businesses to thrive with smaller runs while maintaining profitability. This aspect is critical for startups or small businesses that seek to create unique, customized pieces without the burden of extensive inventory. Thus, embracing DTF transfers empowers companies not only to expand their creative horizons but also to implement cost-effective solutions in their printing operations.

Challenges Facing DTF Printing Technology

Although DTF printing presents numerous merits, it is not without its challenges. One of the primary considerations for businesses is the initial investment required for equipment and setup, which includes purchasing a specialized DTF printer, heat press, and ongoing materials like film and adhesive powders. This financial hurdle might be daunting for newcomers in the custom apparel market, necessitating careful planning and budgeting to ensure profitability.

Furthermore, potential users face a learning curve associated with mastering the DTF process. Unlike traditional printing methods, effective DTF printing requires an understanding of various factors such as printer calibration, optimal heat settings, and proper adhesive application techniques. Without sufficient training and experience, achieving high-quality outputs may prove to be a challenging endeavor. Thus, it’s crucial for those interested in entering the DTF space to invest in education and technical resources to overcome these initial obstacles.

Exploring Market Trends in DTF Transfers

The landscape of DTF transfers is constantly evolving, and it’s essential to stay informed about current market trends. One significant trend is the increasing popularity of DTF printing among small businesses and independent creatives. As this method presents lower startup costs compared to traditional techniques like screen printing, it is becoming a favored choice for those looking to offer personalized apparel, catering to events, promotions, and individual clients with unique designs. This growing demand demonstrates the shifting dynamics in the custom printing market, emphasizing DTF’s ascent as a preferred solution.

In addition, technological advancements continue to enhance DTF printing capabilities. Manufacturers are investing in improved printer technology that promises faster print speeds and better quality outputs. Innovations in eco-friendly materials are also gaining traction, aligning with consumer preferences for sustainable practices. Companies that adopt these advancements not only improve operational efficiency but also position themselves favorably against competitors in an increasingly conscientious market.

Tips for Achieving Success with DTF Transfers

To succeed in DTF transfer printing, one must approach the craft with a strategic mindset. One of the critical tips is to invest in high-quality equipment tailored for DTF printing. A professional-grade DTF printer paired with a reliable heat press ensures that your prints achieve the desired quality consistently, avoiding common pitfalls associated with inferior equipment. It’s essential to recognize that the output’s quality significantly relies on the tools at your disposal.

Additionally, optimizing design files is vital for successful DTF printing. Designs should be created at a high resolution to maintain clarity and prevent pixelation when printed. Utilizing vector files can further enhance the quality, ensuring that intricate details remain sharp in the final product. Testing your prints on various fabric types also allows for evaluation of durability and adherence, which can guide your consultations with clients regarding fabric selection, ultimately leading to satisfied customers and repeat business.

The Future of DTF Transfers in the Printing Industry

As the fabric printing industry evolves, DTF transfers are poised to play an integral role in shaping future trends. With the increasing demand for customization, DTF’s ability to produce high-quality prints quickly and efficiently makes it a valuable option for businesses looking to adapt to consumer needs. The continuous development of more advanced and sustainable DTF printing technologies will likely further entrench the methodology’s reputation as a go-to solution amongst professionals.

Furthermore, the industry is expected to witness an influx of innovative applications of DTF transfers beyond traditional apparel. For example, personalized home decor, promotional items, and custom merchandise are areas ripe for exploration. As businesses tap into these opportunities and harness the potential of DTF technology, they can open new revenue streams while catering to a broader range of customer preferences. Indeed, embracing the future of DTF transfers could lead to unprecedented growth and creativity in the printing sector.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process, or Direct to Film printing, involves printing designs directly onto a special PET film using a DTF printer. In this method, a hot-melt adhesive powder is applied to the wet ink on the film, which is then cured through a heat press. Finally, the film is placed on the desired fabric and heat pressed again to transfer the design. This process allows for vibrant colors and detailed designs on various fabric types.

What are the advantages of using DTF transfers for custom apparel printing?

DTF transfers offer several advantages for custom apparel printing, including versatility to print on a wide range of fabrics such as cotton and polyester. They are known for their durability, resisting fading and peeling even after multiple washes. Another benefit is that DTF printing does not require pre-treatment of fabrics, streamlining production and reducing setup times. Additionally, DTF is economically viable for low minimum runs, making it ideal for small businesses.

How durable are DTF transfers compared to other printing methods?

DTF transfers are highly durable, often surpassing traditional printing methods like screen printing or Direct to Garment (DTG) in longevity. The prints withstand regular washing and wear without significant fading or peeling, thanks to the strong bond created between the ink, adhesive, and fabric. This durability makes DTF transfers a preferred choice for custom apparel that is both stylish and reliable.

What should I consider before investing in DTF printing equipment?

Before investing in DTF printing equipment, consider the initial setup costs, including the printer, heat press, and necessary materials. Be prepared for a learning curve in understanding printer calibration, adhesive application techniques, and optimal heat settings. Regular maintenance of equipment is also crucial to ensure consistent print quality and longevity. Assess your business goals and target market to determine if DTF printing is the right fit for your needs.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are incredibly versatile and can be used on a wide variety of fabric types, including cotton, polyester, silk, and blends. This flexibility allows businesses in the custom apparel printing industry to cater to diverse customer preferences and expand their product offerings. However, it’s essential to test prints on different fabrics to ensure the best results.

How can I ensure the best quality in my DTF prints?

To ensure optimal quality in DTF prints, invest in high-quality printing equipment and maintain it regularly. Create high-resolution designs to avoid pixelation and use vector files when possible. It’s also advisable to perform test prints on various fabric types to determine how the designs hold up over time, guiding customers in fabric selection. Continually update your knowledge on printing techniques and materials to stay competitive in the market.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | A printing technique that applies designs directly onto special film, which is then transferred onto fabrics using heat and adhesive. |

| The DTF Process | Involves printing on PET film, applying adhesive powder, curing the prints, and then transferring designs onto fabric. |

| Advantages of DTF Transfers | Includes versatility on fabric types, durability of prints, no requirement for pre-treatment, and cost-effectiveness for small runs. |

| Challenges and Considerations | Requires initial investment, a learning curve for effective use, and regular equipment maintenance for quality results. |

| Market Trends | Growing popularity in custom printing due to lower costs, advancements in technology, and increasing demand for sustainable solutions. |

| Tips for Successful DTF Printing | Invest in quality equipment, optimize designs, test various fabrics, and continuously learn about new techniques and trends. |

Summary

DTF Transfers are transforming the landscape of fabric printing, offering innovative solutions for custom apparel production. Known for their high-quality prints and versatility across different fabric types, DTF technology provides a considerable advantage for businesses aiming to meet diverse customer demands. Additionally, the method simplifies the printing process by eliminating the need for pre-treatment, and presents a sustainable alternative, inviting a broader market adoption. The challenges of investment and maintaining knowledge about the equipment are manageable with proper planning and dedication. Overall, DTF Transfers represent a bright future in the printing industry, paving the way for creative expansion and improved business opportunities.