In the ever-evolving landscape of textile printing, **DTF Transfers** have emerged as a game-changer, offering unparalleled clarity and vibrancy for custom designs. This innovative approach, known as Direct to Film printing, allows intricate artworks to be transferred onto fabric with remarkable precision. As we delve into the benefits of DTF Transfers, we’ll uncover how this technique streamlines the custom apparel printing process, making it both efficient and cost-effective. Moreover, the DTF printing process not only enhances the quality of prints but also provides a level of versatility that is increasingly sought after in the fashion industry. Whether you’re a professional designer or a DIY enthusiast, discovering the advantages of DTF Transfers will showcase a new world of possibilities in textile creativity.

Exploring advanced methods in textile decoration, Direct to Film Transfers, often referred to as DTF printing techniques, have become essential for modern custom apparel needs. This innovative style of printing utilizes sophisticated processes that yield high-quality and durable designs, surpassing many traditional methods. The appeal of DTF printing lies in its capability to produce vibrant and intricate designs that adhere seamlessly to various fabrics. As the market for custom graphics expands, understanding the DTF printing process opens doors for both small businesses and individual creatives aiming to elevate their products. By embracing these advanced printing technologies, your fashion endeavors can unlock a new realm of creativity and personalization.

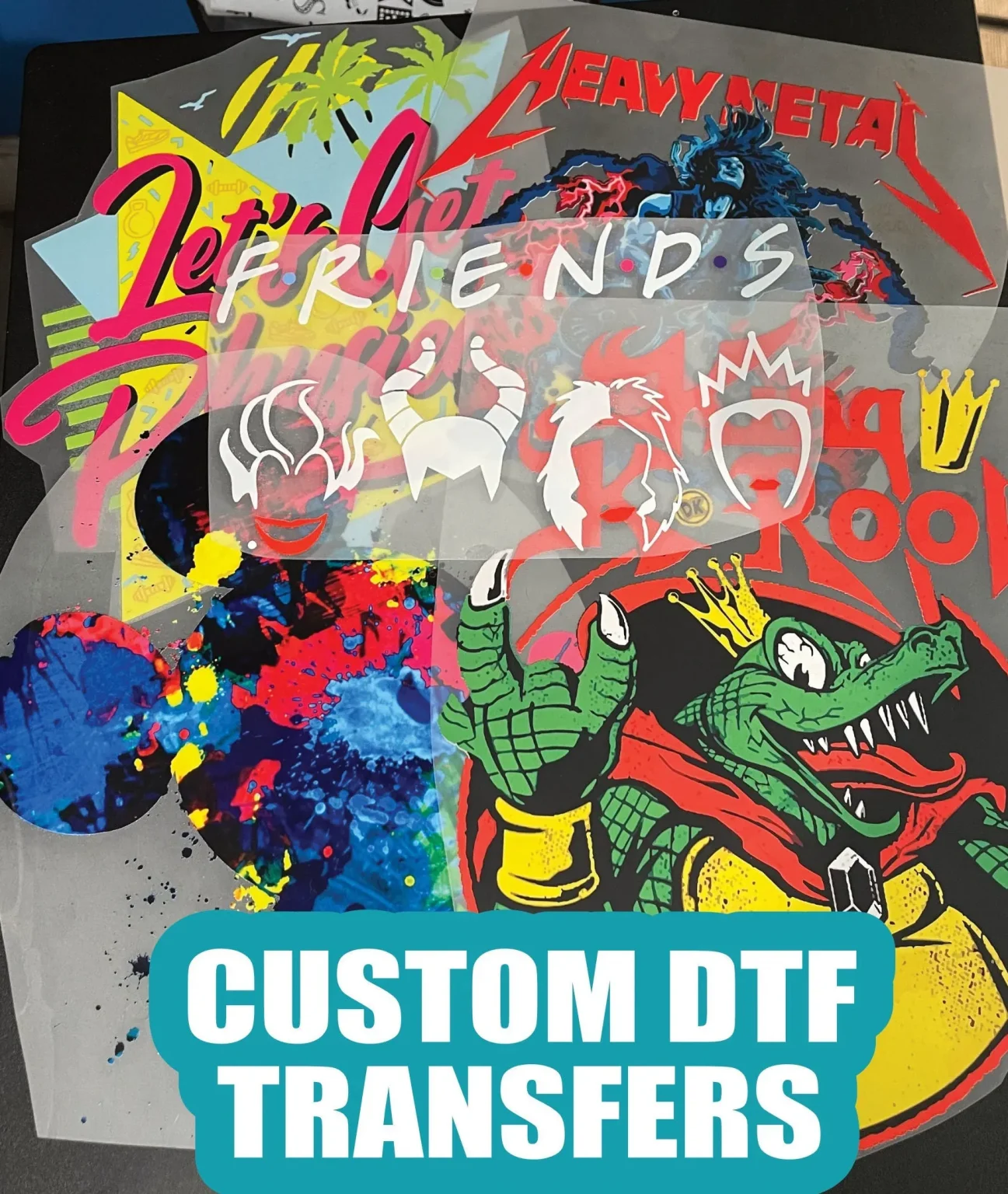

Benefits of DTF Transfers for Custom Apparel Printing

DTF Transfers have emerged as a game-changing method in the realm of custom apparel printing. One of the most notable benefits is their ability to produce vibrant colors that rival other printing techniques. The use of high-quality, water-based pigmented inks ensures that designs maintain their brilliance and clarity, even after multiple washes. This durability is essential for custom apparel, as it guarantees that intricate artworks and full-color graphics remain just as striking as they were on the day of application.

Moreover, DTF Transfers are incredibly versatile, making them highly suitable for a range of fabrics, including cotton, polyester, and blends. This flexibility allows businesses and individuals to create personalized and unique clothing items without having to worry about fabric limitations. As consumer demand for customized clothing continues to rise, DTF Transfers provide a perfect solution for those looking to create bespoke designs that stand the test of time.

Exploring the DTF Printing Process

The DTF printing process is an intricate yet straightforward series of steps that culminate in a high-quality print. Initially, a DTF printer outputs the artwork onto a specialized transfer film. The choice of printer plays a crucial role, as dedicated DTF printers are designed to handle the unique inks and films required for optimal results. Following the printing stage, an adhesive powder is applied to the wet ink, ensuring that the design sticks to the fabric when heat is applied.

After applying the adhesive, the film must be cured using heat, solidifying the bond between the ink and the adhesive. The final stage of the process involves using a heat press to transfer the design onto the desired garment. This method combines heat and pressure to facilitate a durable attachment. Understanding these steps is vital for anyone looking to master DTF Transfers, as each phase significantly impacts the final print quality.

The technology behind the DTF printing process continues to evolve, enhancing user experience and efficiency. For instance, the introduction of pre-coated films has simplified setup procedures, allowing users to bypass adhesive processing. As a result, those involved in custom apparel creation can expect faster production timelines and higher-quality outcomes.

Key DTF Transfer Techniques for Enhanced Creativity

DTF Transfers are not only about the printing process; they also offer a variety of techniques that enable users to elevate their creative designs. One prominent technique is layering, which allows for the combination of multiple images or colors to create depth and texture in a single print. This aesthetic not only makes the clothing visually appealing but also opens up a world of artistic possibilities for designers looking to make a statement.

Another key technique is the ease of customization offered by DTF Transfers. Unlike traditional screen printing, which often requires extensive setup for each design, DTF Transfers streamline the personalization process. Businesses can produce unique garments for specific events, individual clients, or promotional purposes without incurring hefty costs. This capacity for quick turnaround times and unique designs makes DTF Transfers a favored option for custom apparel printing, catering to the fast-paced demands of today’s market.

The Role of DTF Printers and Equipment

To effectively execute DTF Transfers, the right equipment is crucial. DTF printers are specially designed to handle the unique inks and films used in this printing technique. These printers utilize advanced technology to produce high-quality prints with precision, ensuring that color vibrancy and detail are maintained throughout the process. Investing in a reliable DTF printer is a significant step for businesses looking to enter the custom apparel market.

In addition to the printer, essential materials such as high-quality transfer films and a proficient heat press are needed to achieve successful results. The choice of adhesive powder also plays a vital role in the process, as it must be compatible with both the ink and the fabric. As the market for DTF Transfers continues to grow, having the right tools and technology positions businesses to meet consumer demands for quality and customization effectively.

Sustainable Printing with DTF Transfers

With increasing awareness about environmental sustainability, DTF Transfers are gaining attention as an eco-friendly printing option. Many DTF printing materials utilize water-based inks, which significantly reduce the environmental impact compared to traditional plastic-based inks used in other printing methods. This transition to greener options is appealing both to environmentally conscious consumers and companies looking to minimize their carbon footprint.

Moreover, the durability of DTF Transfers means that garments printed using this method last longer, ultimately contributing to less waste and a lower frequency of replacements. By choosing DTF Transfers, textile decorators can promote sustainable practices while still delivering vibrant and high-quality designs. This ecological advantage places DTF Transfers at the forefront of ethical printing solutions in the fashion and merchandising industries.

Future Trends in DTF Transfers and Technology

As technology advances, the future of DTF Transfers looks promising. Recent developments include innovations in ink formulations that enhance adhesion and washability, ensuring that printed designs endure over time. These advancements not only improve the overall quality of the prints but also expand the capabilities of DTF printing, allowing for more intricate and diverse applications in custom apparel.

Moreover, the market for DTF Transfers is expected to grow as small businesses and independent creators increasingly adopt this printing technique for high-quality and cost-effective solutions. With ongoing advancements in printing technology, we can anticipate refinements in efficiency and accessibility, making DTF Transfers a key player in the textile printing landscape. By keeping an eye on these trends, businesses can stay ahead of the curve and offer innovative products that appeal to modern consumers.

Frequently Asked Questions

What are DTF Transfers and how does the DTF printing process work?

DTF Transfers, or Direct to Film Transfers, involve printing designs onto a special film that is then heat transferred onto fabric. The DTF printing process includes printing the design with DTF printers using water-based inks, applying adhesive powder, curing the adhesive with heat, and finally using a heat press to transfer the design to the fabric, ensuring a strong bond.

What are the benefits of using DTF Transfers for custom apparel printing?

The benefits of DTF Transfers include vibrant color output, exceptional durability, user-friendly processes, and cost-effectiveness for small production runs. Additionally, DTF Transfers utilize eco-friendly water-based inks, making them a sustainable choice for custom apparel printing.

How do DTF printing techniques compare to other printing methods?

DTF printing techniques stand out for their ability to produce intricate, multi-colored designs with high durability and flexibility. Unlike methods like screen printing that require more setup and resources, DTF Transfers accommodate a variety of fabric types and are easier to use, making them ideal for both small and large-scale custom apparel projects.

What materials are essential for the DTF Transfers process?

Key materials for DTF Transfers include a specialized DTF printer, adhesive powder for ensuring the design adheres to the fabric, a heat press to apply the necessary heat, and high-quality transfer films capable of withstanding the printing and heat transfer stages.

Are DTF Transfers suitable for various fabric types?

Yes, DTF Transfers are versatile and compatible with multiple fabric types, including cotton, polyester, and blends. This flexibility allows for a wide range of applications in custom apparel printing, making DTF Transfers an excellent choice for diverse merchandising options.

What recent developments in DTF Transfers are making the process more efficient?

Recent developments in DTF Transfers include the introduction of pre-coated films which streamline the printing process by reducing setup time, and advancements in ink formulations that enhance adhesion and washability. These innovations contribute to improved quality and accessibility of DTF printing technology.

| Key Point | Description |

|---|---|

| Introduction | Overview of DTF Transfers and their significance in textile printing. |

| Understanding DTF Transfers | DTF Transfers involve printing designs onto a film that is heat transferred to fabric, offering high-quality prints. |

| Printing Process Steps | 1. Print design on DTF film, 2. Apply adhesive powder, 3. Cure adhesive, 4. Heat transfer onto fabric. |

| Required Materials | Key materials include DTF printers, adhesive powder, heat press, and transfer film. |

| Techniques | Layering for depth, customization for personal designs, and compatibility with various fabrics. |

| Benefits | 1. Vibrant colors, 2. Durability, 3. Ease of use, 4. Cost-effective, 5. Eco-friendly options. |

| Recent Developments | Introduction of pre-coated films, better inks, and market growth in small business applications. |

Summary

DTF Transfers have revolutionized the world of custom apparel printing, providing an innovative and efficient method for creating vibrant textile designs. By allowing for high-quality, durable prints that can be customized for various fabric types, DTF Transfers present a versatile solution for businesses and individuals looking to elevate their creative projects. As advancements continue in printing technology, DTF Transfers are poised to lead the industry with cutting-edge techniques and sustainable practices, making them an essential option for modern textile printing.