In the dynamic realm of custom apparel printing, **DTF Transfers** (Direct to Film Transfers) have emerged as a game-changer for businesses looking to modernize their garment production processes. This innovative printing technique stands out from traditional printing methods, such as screen printing and heat transfer, by offering increased versatility and vibrant color outputs. DTF printing advantages include lower setup costs, making it an appealing choice for small runs and unique designs. As the demand for personalized apparel surges, understanding the benefits and limitations of DTF transfers becomes crucial for businesses striving to meet consumer expectations. Join us as we delve deeper into the world of DTF printing and explore how it compares to established methods in the industry.

In the evolving landscape of textile printing, the decision between various printing techniques can significantly impact a brand’s offering. When considering alternatives for custom apparel creation, terms like Direct to Film printing and transfer methods are gaining traction due to their efficiency and quality. As businesses weigh the options of heat press applications versus traditional screen printing, understanding the nuances between these methodologies is essential. Techniques like these are particularly noteworthy for their ability to provide engaging visuals on fabric while catering to small batch needs and highly detailed designs. Let’s examine how these contemporary methods stack up against longstanding practices to determine the best fit for your printing projects.

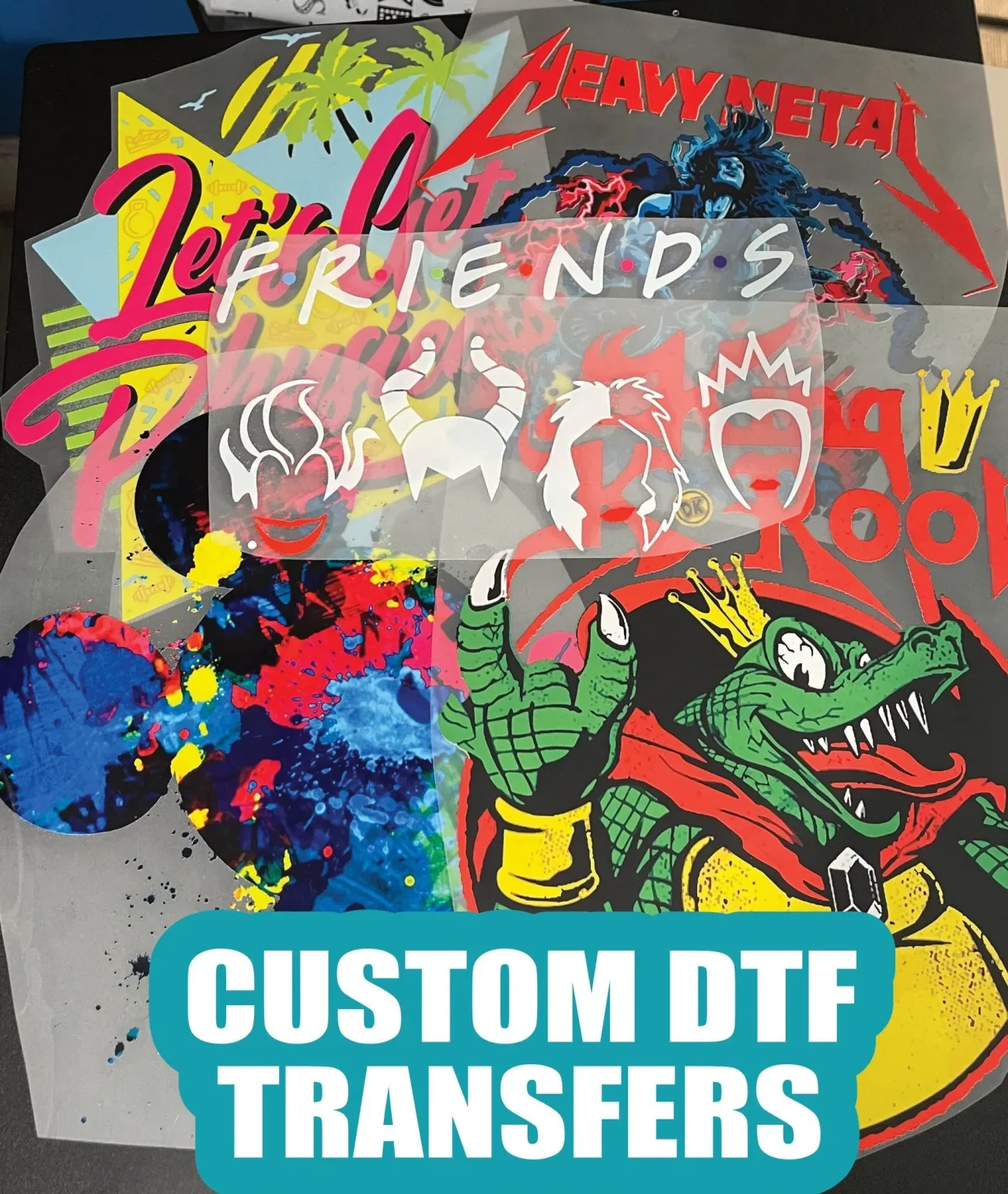

Exploring the Versatility of DTF Transfers

DTF Transfers have revolutionized the garment printing industry with their broad versatility. Unlike traditional printing methods, such as screen printing, which often struggle with various fabric types, DTF printing excels on a wide array of materials. It works seamlessly on cotton, polyester, and mixed fabric blends, allowing businesses to cater to diverse customer needs. This adaptability makes DTF a perfect choice for custom apparel printing, as it can easily accommodate different fabric colors and textures.

Furthermore, the application process of DTF printing adds to its versatile nature. The ability to print intricate designs with vibrant colors on both light and dark fabrics sets it apart from heat transfers, which can sometimes lose vibrancy on darker surfaces. As a result, businesses can confidently embrace DTF transfers for a wide range of garments, ensuring that the final product meets customer expectations for quality and aesthetic appeal.

DTF Printing Advantages Over Traditional Methods

When it comes to the advantages of DTF printing, there are several standout features that make it preferable for many business owners. One significant advantage is the lower setup costs compared to traditional screen printing. For businesses focusing on small runs or unique custom jobs, DTF printing allows for greater flexibility without the burden of high initial costs. This economic efficiency ensures that even small businesses can thrive in a competitive market.

Additionally, DTF printing produces vibrant colors with intricate details that are often superior to those achieved by traditional methods. This technology provides a broad color gamut, meaning that your designs maintain their richness and depth, appealing to consumers who desire eye-catching graphics. Furthermore, the durability of DTF prints ensures they withstand numerous washes while remaining unchanged in quality, which traditional heat transfer methods may not visually replicate.

Limitations of DTF Printing to Consider

Despite its many advantages, DTF printing comes with its own set of limitations that business owners need to consider. One of the primary concerns is the initial investment in DTF printers and associated equipment, which can be significant. This cost may present a barrier to entry for smaller startups or businesses that are just beginning to explore custom apparel printing.

In addition to the equipment expenses, there is also a learning curve associated with DTF printing technology. Newcomers to this method must familiarize themselves with the specifics of file setup and the transfer process to produce quality outputs. While many might find DTF transfers advantageous, understanding these limitations is crucial for making an informed choice about whether to adopt this modern printing method.

Understanding Traditional Printing Methods: Screen Printing and Heat Transfer

Traditional printing methods like screen printing and heat transfer have long been the go-to choices for businesses and individual projects alike. Screen printing, in particular, is highly regarded for its durability and color fidelity, making it ideal for large batches of garments. However, this method requires a meticulous setup process, often involving creating separate screens for every color in the design, leading to increased time and costs.

On the other hand, heat transfer is favored for its accessibility and simplicity, making it an appealing option for individuals and small businesses celebrating events or launching new merchandise. Though it is easy to use, heat transfer may not rival DTF printing in terms of vibrancy and durability, especially on darker fabrics. Understanding these traditional methods is essential when deciding between them and newer techniques like DTF.

The Comparative Quality of DTF and Traditional Printing

Quality is a significant factor when choosing between DTF transfers and traditional printing methods. DTF printing typically offers a higher quality output, characterized by enhanced detail and vibrant colors. This advantage is primarily due to the specialized inks used alongside the innovative application process, ensuring that designs pop and attract attention. For brands looking to make a strong impression, DTF’s ability to deliver superior quality is undeniable.

Conversely, traditional methods such as screen printing can still produce high-quality results, particularly when utilized for bulk orders. However, the color richness and detail may not match that of DTF prints, especially for intricate designs. As businesses navigate the printing landscape, understanding the qualitative differences can greatly influence their decision-making process and ultimately affect customer satisfaction.

Current Trends Shaping the Printing Industry

The printing industry is currently witnessing a significant shift towards personalized and custom apparel, with DTF printing at the forefront of this revolution. Businesses transitioning from traditional methods are capitalizing on the operational cost savings and high-quality outputs that DTF technology offers. This trend reflects a broader consumer demand for unique and high-impact designs, driving companies to seek more versatile and efficient printing solutions.

As more entrepreneurs explore the opportunities presented by DTF printing, discussions within community forums and blogs have become increasingly geared towards its advantages over conventional methods. Topics range from the technical aspects of DTF applications to success stories of businesses achieving growth through this modern approach. Staying informed on these trends is vital for businesses aiming to align their offerings with market demands and consumer preferences.

Frequently Asked Questions

What are the main advantages of DTF Transfers compared to traditional printing methods?

DTF Transfers, or Direct to Film Transfers, offer several advantages over traditional printing methods like screen printing and heat transfer. DTF is known for its versatility, allowing it to be applied to a wide range of materials, including both light and dark fabrics. It produces vibrant colors and intricate details, ensuring high-quality outputs that remain durable through numerous wash cycles. Additionally, DTF printing has lower setup costs, making it ideal for small runs or custom orders.

How do DTF Transfers compare to screen printing?

When comparing DTF Transfers to screen printing, DTF generally provides a quicker setup and is more cost-effective for small orders. While screen printing is excellent for bulk production, as it offers high durability and color fidelity, it requires more time for setup. DTF Transfers can produce detailed and vibrant artwork on various fabrics, making it a flexible alternative, especially for custom apparel.

Can DTF Transfers be used on dark fabrics effectively?

Yes, DTF Transfers work exceptionally well on dark fabrics. This is one of the standout advantages of DTF printing compared to traditional heat transfer methods, which may struggle with vibrancy on darker materials. DTF technology allows for rich colors and sharp details regardless of the base fabric color.

What types of materials are compatible with DTF Transfers?

DTF Transfers are compatible with a wide array of materials, including cotton, polyester, and various fabric blends. This versatility makes DTF a preferred choice for many businesses looking to offer custom apparel printing on different substrates, unlike some traditional methods that may have specific limitations.

Are DTF Transfers durable in comparison to heat transfer methods?

Absolutely. DTF Transfers provide superior durability compared to traditional heat transfer methods. Prints made with DTF technology typically withstand multiple wash cycles without fading significantly, making them more reliable for both personal and commercial use.

What should I consider when choosing between DTF Transfers and heat transfer methods?

When choosing between DTF Transfers and traditional heat transfer methods, consider factors such as the types of materials you’ll be printing on, the volume of prints needed, and your budget. DTF typically offers better quality, durability, and versatility. However, traditional heat transfer may be easier for beginners and suitable for lower volume jobs.

| Aspect | DTF Transfers | Traditional Methods |

|---|---|---|

| Quality | More vibrant and detailed. | Good quality, particularly for bulk orders. |

| Durability | Lasts longer through washes with minimal fading. | Can fade more quickly, especially on darker fabrics. |

| Setup Costs | Generally lower for smaller runs and custom jobs. | Higher, especially for screen printing with time-consuming setups. |

| Material Compatibility | Wide range of fabrics including cotton, polyester, and blends. | Limitations on fabric types, often better for certain materials. |

Summary

DTF Transfers offer a modern and highly efficient solution for garment printing, distinguishing themselves from traditional methods like screen printing and heat transfer. With benefits such as vibrant colors, durability, versatility across various materials, and lower setup costs, DTF Transfers are quickly becoming the preferred choice for businesses aiming to deliver customized apparel. As trends evolve towards personalized clothing, understanding the key advantages and possible drawbacks of DTF printing can empower businesses to make informed decisions that align with their unique requirements and consumer expectations. Whether you opt for DTF Transfers or traditional methods ultimately depends on the specific needs of your printing projects.