In the ever-evolving landscape of custom apparel printing, DTF transfers have emerged as a game-changing technology that brings together the ease of digital printing and the quality of traditional methods. Direct-to-Film (DTF) transfers offer vibrant, long-lasting designs that appeal to both businesses and individual creators, making them a fantastic choice for a variety of fabric types. Unlike traditional printing methods such as screen printing and heat transfer vinyl, DTF printing technology boasts flexibility and lower setup costs, which are perfect for smaller businesses or one-off projects. This innovative approach ensures that designs remain bright and durable, even after repeated washings. As custom printing becomes increasingly popular, understanding the advantages of DTF transfers can help you make informed decisions about your projects and needs in this competitive market.

In the realm of personalized printing solutions, the advent of Direct-to-Film (DTF) technology has revolutionized the way designs are transferred onto fabrics. This method, which stands alongside established techniques like screen printing and heat transfer vinyl, presents a unique blend of versatility and efficiency for custom apparel and promotional items. DTF transfers not only facilitate vibrant color reproduction but also adapt well to various textile materials, unlike some traditional alternatives. With an increasing number of businesses gravitating towards DTF printing, the need to evaluate all printing methods has never been more pertinent. As the printing industry evolves, exploring these diverse techniques will empower creators to select the best fit for their artistic vision and operational goals.

Understanding DTF Transfers: A Modern Printing Solution

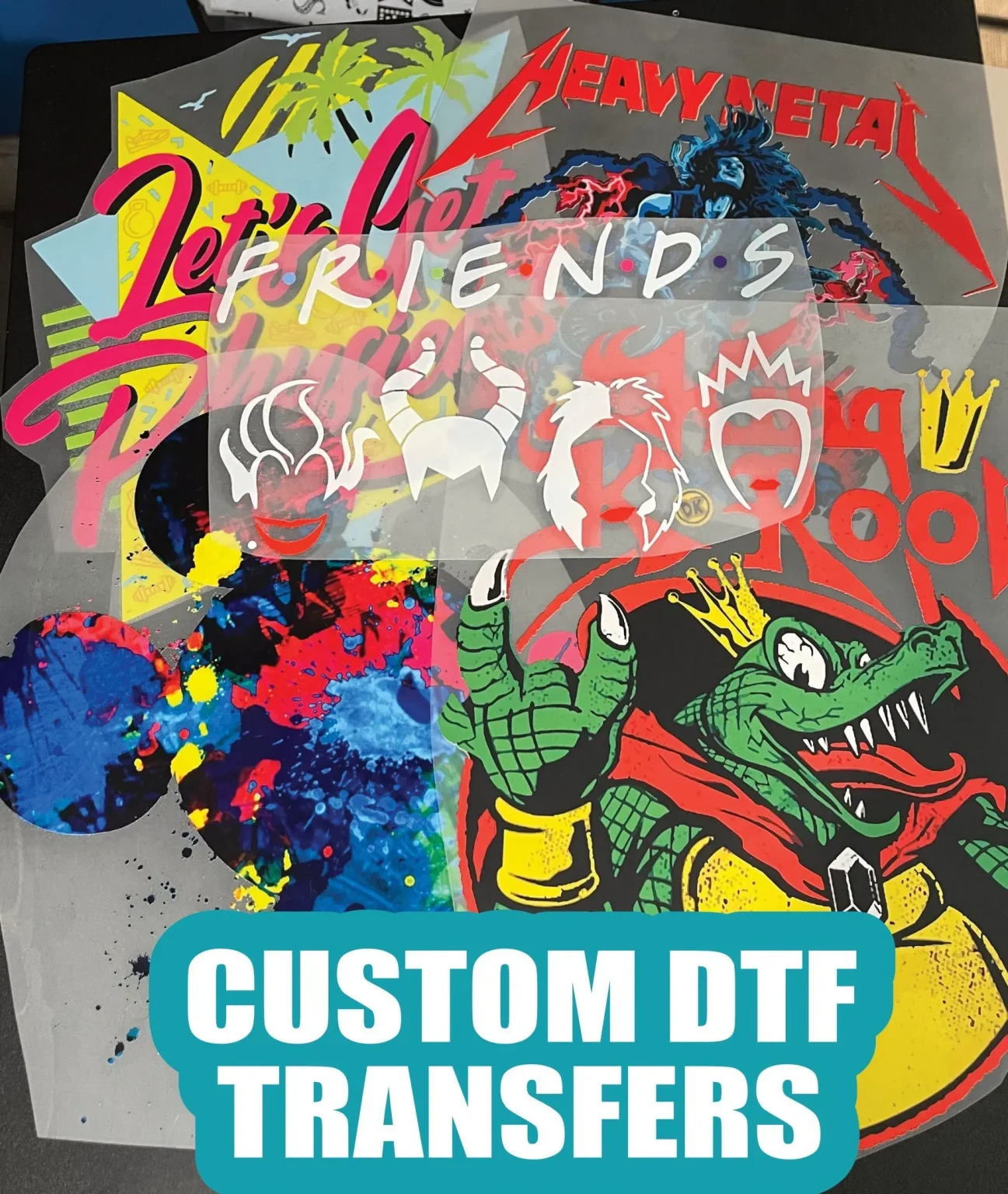

Direct-to-Film (DTF) transfers have quickly emerged as a popular choice in the world of custom apparel printing. Unlike traditional methods that may require complex setups, DTF printing technology uses a straightforward approach to create vibrant, high-quality designs. This method utilizes a specialized film that adheres to various fabrics, allowing the prints to maintain their vivid colors and sharp details, even after prolonged use. In today’s marketplace, where consumers seek unique and personalized items, DTF offers a level of versatility that many traditional printing techniques cannot match.

One of the most significant advantages of DTF transfers is their ability to work with an array of materials, including cotton, polyester, and blends of both. This flexibility makes them suitable for various applications, from custom t-shirts to promotional items. Furthermore, DTF printing can effortlessly accommodate intricate designs and color gradations, giving businesses the freedom to explore creative opportunities that appeal to their target audience.

Exploring Traditional Printing Methods

Traditional printing methods, such as screen printing and heat transfer vinyl, have long been staples in the custom printing industry. Screen printing, in particular, is renowned for its ability to produce rich colors and detailed graphics. This method involves pushing ink through mesh screens, which allows for the creation of durable prints that can withstand multiple washes. However, it comes with a higher upfront setup cost, making it less feasible for smaller production runs.

Heat transfer vinyl (HTV), another traditional method, offers a different set of advantages and challenges. HTV is suitable for simpler designs and can be applied quickly, making it ideal for short-term projects. Nevertheless, HTV may not adhere as seamlessly to the fabric as DTF transfers, which can lead to visible edges or a feeling of detachment from the garment. Additionally, while HTV can be effective for specific applications, it faces durability concerns over time, particularly with frequent washing.

Advantages of Choosing DTF Printing

DTF printing offers a myriad of benefits that cater to both personal and professional printing needs. One of the most notable advantages is its cost-effectiveness, especially when considering small orders or one-off projects. With lower setup costs compared to traditional screen printing, DTF technology enables businesses to experiment with designs without the financial burden of large-scale production.

In addition to its economic advantages, DTF transfers excel in color vibrancy and durability. The prints created using this technology maintain their brilliance even after multiple washes, ensuring that the end product not only looks striking upon delivery but also stands the test of time. As a result, businesses can deliver high-quality, long-lasting products that meet the growing demands of today’s customization market.

Key Limitations of DTF Transfers

Despite the growing popularity and advantages of DTF transfers, there are limitations that need to be addressed. One primary concern is the longevity of DTF prints compared to traditional methods. While DTF prints generally hold up well, they can be susceptible to fading or cracking under harsh laundering conditions. Businesses must carefully consider the intended use of their products and ensure that care instructions are clearly communicated to consumers.

Another limitation is consumer perception and market acceptance. Many customers may still prefer traditional methods like screen printing, as they have been tried and tested over decades. This established trust can impact the willingness of consumers to adopt newer technologies like DTF printing, even when the quality of the outputs is comparable or superior.

A Comparative Look: DTF Transfers vs. Screen Printing

When comparing DTF transfers to screen printing, several factors come to light that can influence your choice. Screen printing is often favored for its robustness and the ability to produce large quantities efficiently. This method is particularly advantageous for businesses intending to run large volume orders, as it can lower per-unit costs significantly. On the other hand, DTF printing shines when it comes to customization and flexibility, allowing for full-color designs without the constraints of minimum order requirements.

In terms of setup and ease of use, DTF technology requires less equipment and comes with a learning curve that many users find manageable. The convenience of DTF printing makes it an appealing option for smaller businesses or individuals who may not have access to the extensive machinery needed for screen printing. Ultimately, the choice between these two methods depends on specific project goals, order sizes, and the desired aesthetic of the finished product.

Future Trends in Custom Printing: Embracing DTF Technology

As we enter a new era of custom printing, the trend towards DTF transfers continues to grow. With an increase in e-commerce and personalized products, businesses are turning to DTF technology to meet these evolving demands. As reports highlight, this upward trend is fueled by technological advancements that improve the efficiency and quality of DTF printing, leading to greater accessibility for businesses and consumers alike.

Moreover, as more businesses adopt DTF printing, we can expect to see a shift in market preferences. Consumers are becoming more informed about their options, allowing for a broader acceptance of innovative methods like DTF. This transition has the potential to reshape the custom apparel landscape, pushing traditional methods like screen printing and HTV to adapt or innovate to stay relevant in a competitive market.

Frequently Asked Questions

What are DTF transfers and how do they differ from traditional printing methods?

DTF transfers, or Direct-to-Film transfers, use a specialized film to print designs, allowing for vibrant and durable outputs on various fabrics. Unlike traditional methods, such as screen printing, which are often limited to specific materials and require higher setup costs, DTF printing technology provides a versatile, cost-effective solution for both small and large projects.

Are DTF transfers suitable for all types of fabrics?

Yes, DTF transfers are highly versatile and can be applied to a wide range of fabrics, including cotton, polyester blends, and dark materials. This adaptability makes DTF printing an excellent choice for custom apparel printing, compared to traditional printing methods like heat transfer vinyl (HTV) that may not perform as well on certain fabrics.

What advantages do DTF transfers offer over screen printing?

DTF transfers provide several advantages over screen printing, including lower setup costs, the ability to print on dark or varied fabrics, and vibrant color retention even after multiple washes. This modern printing technology allows for high-quality, detailed designs at a fraction of the cost for smaller runs, making it ideal for custom apparel businesses.

Can I achieve the same durability with DTF transfers as with traditional screen printing?

While DTF transfers are durable and hold color well, they may not match the longevity of traditional screen printing in harsh conditions or heavy laundering. Nevertheless, when properly cared for, DTF prints can still deliver excellent durability, especially for everyday wear in custom apparel.

What limitations should I consider when choosing DTF printing technology?

One limitation of DTF transfers is their relatively new market presence, which may lead to varying consumer acceptance compared to established methods like screen printing. Additionally, while setup costs are lower, certain DTF prints may have durability challenges under harsh treatment, necessitating careful selection for specific applications.

How does DTF printing impact the custom apparel printing market?

DTF printing is transforming the custom apparel printing market by offering a cost-effective, high-quality solution for small orders and personalized items. As e-commerce demand rises, many businesses are adopting DTF technology to stay competitive against traditional printing methods, capitalizing on its versatility and vibrant outputs.

| Key Points | DTF Transfers | Traditional Printing |

|---|---|---|

| Overview | Utilizes specially coated film to print on various fabrics; high-quality and vibrant outputs. | Screen printing forces ink through a mesh screen; great for vibrant and durable prints but has high setup costs. |

| Key Advantages | – Versatile for many fabrics. – Maintains color vibrancy. – Lower setup costs. – Easy to use with minimal equipment. |

– Excellent for bulk orders. – Vibrant, long-lasting colors. – Established method with a proven track record. |

| Limitations | – Durability concerns under harsh conditions. – Market acceptance is still growing. |

– High initial setup costs. – Less adaptable for small runs; durability varies with design. |

| Recent Trends | Increasing adoption for custom apparel and promotions. Cost-effective and effective printing capabilities highlight DTF’s growth. | Established and trusted method; continues to dominate in bulk printing. |

Summary

DTF transfers represent a significant innovation in the custom printing industry, offering diverse advantages that cater to modern needs. As businesses and individuals navigate the landscape of custom printing, understanding the strengths of DTF transfers—including vibrant colors, versatility across fabric types, and cost-effectiveness—can lead to informed decisions. Choosing the right method—whether DTF or traditional—depends on specific project requirements, budget constraints, and the desired outcome. By carefully considering these factors, printers can optimize their workflows and meet their customers’ expectations effectively.