In the world of custom apparel printing, the discussion of DTF vs. DTG printing has gained significant traction among businesses seeking the best solution for their needs. Each printing method presents unique advantages and features that cater to various applications, making them both contenders in the printing methods comparison. DTF printing benefits from its versatility across different fabric types and its cost-effectiveness for larger orders, while DTG printing advantages include high-resolution prints and an eco-friendly approach using water-based inks. As printing technology trends continue to evolve, understanding the distinctions between DTF and DTG will become increasingly important for businesses aiming to capitalize on these innovative techniques. This guide will delve deeper into each method, exploring the intricacies to help you determine which method reigns supreme in your specific printing endeavors.

When considering direct-to-film and direct-to-garment printing techniques, it’s important to recognize the fundamental differences that set them apart in the realm of textile manufacturing. These innovative printing solutions provide a modern approach to create vibrant, eye-catching designs, meeting the demands of today’s custom apparel market. By examining the strengths and weaknesses of these methods, businesses can align their printing strategy with operational goals, ensuring optimal quality and efficiency. Whether you are drawn to the cost savings and versatility of the film method or the high-quality, intricate designs enabled by garment printing, each option has its allure. Let’s explore these printing technologies further to see how they can enhance your creative and production processes.

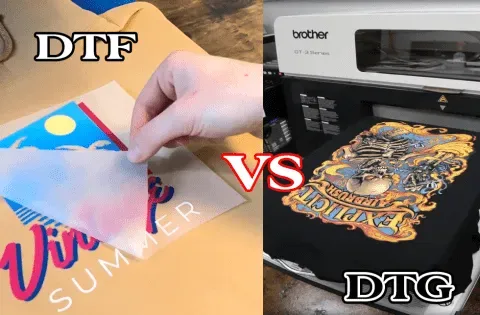

Understanding the Key Differences Between DTF and DTG Printing

Direct-to-Film (DTF) and Direct-to-Garment (DTG) are two cutting-edge printing techniques that have revolutionized the custom apparel industry. Both methods offer distinct advantages, but they cater to different needs and preferences in printing applications. DTF printing is recognized for its versatility, enabling high-quality prints on various fabrics, making it a favorite for businesses interested in a wide product range. In contrast, DTG printing excels in producing high-resolution images, thereby appealing to those who prioritize design complexity and intricate details.

The primary distinction between the two methods lies in their application process. DTF printing transfers ink from a film onto fabric using heat, allowing for a broader selection of material compatibility. Meanwhile, DTG printing uses specialized inkjet technology to apply ink directly onto garments, primarily working best with cotton and cotton-blend fabrics. Therefore, businesses should carefully assess their material needs and the type of design they wish to achieve, as these factors heavily influence the decision between DTF and DTG.

Benefits of DTF Printing for Custom Apparel

DTF printing stands out in the custom apparel landscape for its cost efficiency, especially when producing larger batches. This makes it an attractive option for small businesses and startups, as they can save significantly on printing costs while still providing high-quality products. Furthermore, DTF’s ability to print on various materials opens up possibilities for many different applications, from clothing to promotional items such as bags and hats.

Additionally, DTF prints are known for their durability and softness, which appeals to consumers looking for comfortable, long-lasting clothing. The print’s vibrant colors and ability to withstand multiple washes without significant fading make it a preferred choice for many customers. As businesses aim to enhance product offerings, DTF printing provides a practical solution that also meets growing consumer expectations for quality and longevity in apparel.

Exploring the Advantages of DTG Printing Technology

DTG printing technology has become synonymous with high-resolution, detailed prints, catering to businesses that emphasize artistic design in their apparel. This method allows for the creation of intricate graphics with a level of color depth and clarity that sets DTG apart from traditional printing methods. As a result, those looking to offer custom designs that require precision and artistry often find DTG to be the more suitable option.

Moreover, environmental considerations play a crucial role in the popularity of DTG printing. Utilizing water-based inks, DTG is generally considered more eco-friendly compared to other printing techniques, such as DTF, which may use different ink compositions. This sustainability aspect resonates well with environmentally-conscious consumers, positioning businesses that offer DTG printed products as more responsible and appealing options in a competitive market.

Analyzing Cost Implications: DTF vs. DTG

When comparing the cost implications of DTF versus DTG printing, it is essential to consider both initial setup and ongoing production expenses. DTF printing typically incurs lower up-front costs, especially for bulk orders, making it a favorable option for companies looking to maximize profitability on larger runs. This financial advantage can significantly influence a company’s decision, particularly for smaller outfits that have to be conscious of their budget.

Conversely, while the initial investment for DTG equipment can be higher, businesses benefit from the ability to produce highly customized items on a simpler scale. The flexibility to print on-demand minimizes waste, allowing customers to order shorter runs without incurring high costs. Therefore, understanding the target market and production goals is crucial when evaluating the cost-effectiveness of either method.

The Impact of Printing Technology Trends on DTF and DTG

As we move towards 2025, the advancements in printing technology are significantly shaping how both DTF and DTG methods are implemented in the industry. Innovations within these technologies are enabling quicker turnaround times and greater customization options, which are vital in meeting the demands of consumers in the fast-paced fashion world. Businesses that adapt to these trends will be better positioned to compete and satisfy customer expectations for unique, high-quality apparel.

Moreover, the rise in eco-awareness among consumers is pushing printing companies to seek more sustainable practices in both DTF and DTG methods. As advancements continue, ink formulations and machinery are evolving, potentially improving the performance and eco-friendliness of each printing method. This trend highlights the necessity for businesses to stay informed and continually assess how technological growth impacts production methods, ultimately driving decision-making.

Choosing the Right Printing Method for Your Business Needs

Determining the right printing method for your business is a nuanced decision that requires careful consideration of various factors. These include the types of garments being printed, specific customer preferences, and the scale of production. For instance, companies focusing on high-quality artistic designs may lean towards DTG, while those prioritizing diverse material options might find DTF a better fit. Understanding your market and aligning your printing method accordingly can lead to improved customer satisfaction and business success.

Ultimately, both DTF and DTG printing methods possess unique advantages and may even complement each other in some businesses. Companies should evaluate their current and future needs, remain adaptable to technological changes, and choose a method that aligns with their product vision. As printing technologies continue to evolve, maintaining flexibility in approach will be essential for thriving in the dynamic landscape of custom apparel printing.

Frequently Asked Questions

What is the primary difference between DTF vs. DTG printing?

The main difference between DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing lies in their application processes. DTF printing transfers ink from a film to fabric using heat, making it versatile for different materials, while DTG prints directly onto garments using specialized inkjet technology, achieving high-resolution designs but requiring compatible fabric types.

What are the key advantages of DTF printing in comparison to DTG printing?

DTF printing offers several advantages over DTG printing, including greater versatility across various fabric types, cost-efficiency for bulk orders, and high durability of prints. DTF is particularly effective for custom apparel printing, allowing businesses to expand their offerings without fabric restrictions.

Which printing method, DTF or DTG, is more environmentally friendly?

DTG printing is generally considered more environmentally friendly than DTF due to its use of water-based inks that are less harmful to the environment. As consumers increasingly seek sustainable options, businesses may opt for DTG printing to align with eco-conscious practices.

How do DTF and DTG printing methods compare in terms of print quality?

In terms of print quality, DTG printing is superior for detailed designs and high-resolution prints, making it ideal for intricate artwork. Conversely, DTF printing also provides good quality and durability, but may not achieve the same level of detail as DTG, depending on the design’s complexity.

What are the setup and maintenance requirements for DTF vs. DTG printing?

DTG printing requires more extensive setup and maintenance due to its sensitivity to factors like humidity. It necessitates regular cleaning and upkeep to maintain print quality. In contrast, DTF printing is more straightforward with less stringent maintenance, making it suitable for businesses needing quick turnaround times.

Which printing technology trend is more beneficial for custom apparel businesses: DTF or DTG?

Both DTF and DTG printing methods offer benefits for custom apparel businesses. DTF’s cost-effectiveness and fabric versatility make it appealing for larger batches, while DTG’s high-quality prints cater to intricate designs. The best choice depends on the specific needs of the business, such as design complexity, production volume, and environmental considerations.

| Aspect | DTF Printing | DTG Printing |

|---|---|---|

| Versatility | Highly versatile; works on various fabrics including cotton and polyester. | Specializes in high-quality prints but limited to certain fabric types. |

| Cost Efficiency | More economical, particularly for large batches. Suitable for small businesses. | Higher initial and operational costs, more suited for low-volume custom orders. |

| Durability | Durable with vibrant colors; care dependent factors. | High-quality prints with good detail but may degrade faster under improper care. |

| Print Quality | Good quality but not as detailed as DTG. | Excellent for intricate designs and multi-color prints. |

| Environmental Impact | Less eco-friendly, inks can be harmful. | Uses water-based inks, making it more sustainable. |

| Setup & Maintenance | Simpler setup process; lower maintenance. | Requires more setup time and regular maintenance; sensitive to humidity. |

Summary

When considering DTF vs. DTG printing, the decision largely depends on your specific printing needs and business goals. DTF printing is recognized for its versatility, cost efficiency, and durability, catering well to businesses with a wide range of fabric requirements. Conversely, DTG printing stands out for its exceptional print quality and eco-friendliness, ideal for detailed designs and small production runs. Both methods have their unique advantages and limitations, making it crucial for businesses to analyze their requirements thoroughly before choosing between DTF and DTG solutions to ensure they align with their production needs and market trends.