When exploring the world of custom apparel printing, the debate between DTF vs. DTG emerges as a crucial decision for many businesses. Direct-to-Film (DTF) and Direct-to-Garment (DTG) represent two different approaches, each catering to unique printing needs and fabric types. DTF printing shines with its versatility, capable of producing vibrant images on a wide range of materials, while DTG printing excels in creating detailed, high-quality designs directly on garments. In this guide, we will delve into the nuances of these methods, highlighting their advantages, applications, and the best scenarios for utilizing them in your printing endeavors. Whether you’re a small business or an independent creator, understanding the similarities and differences between DTF and DTG will empower you to make an informed choice to elevate your apparel offerings.

The landscape of fabric printing has evolved significantly, introducing two prominent techniques often referred to as direct film printing and direct garment printing. Both methods employ advanced technology to deliver high-quality prints but differ fundamentally in their processes and applications. The first technique, which utilizes a transfer film, offers versatility across various fabric types, whereas the second method involves direct ink application onto the material. By understanding these alternative terms, you can better appreciate the advantages of each approach and determine which best suits your business’s needs in custom apparel production. This exploration of DTF and DTG will provide valuable insights into choosing the right printing strategy for your creative projects.

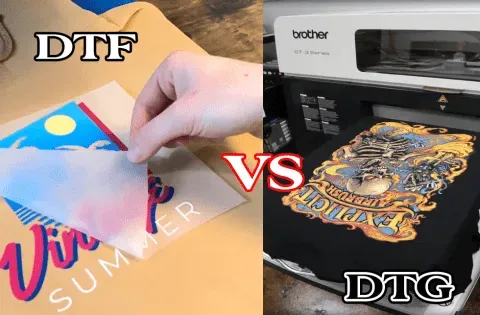

Comparing DTF and DTG Printing Methods

When discussing custom apparel printing, DTF vs. DTG is a conversation that arises often. Both techniques aim to produce high-quality designs, yet they differ significantly in their processes and outcomes. DTF, or Direct-to-Film printing, utilizes a film transfer that is printed with vibrant colors and adhesive powder before being heat pressed onto the fabric. This method allows for excellent versatility as it works on various types of materials, making it an appealing choice for those looking to diversify their product offering. Meanwhile, DTG, or Direct-to-Garment printing, employs inkjet technology to apply inks directly onto the fabric, creating highly detailed and soft prints ideal for cotton-based products. Thus, understanding the distinctions between these two methods is crucial for businesses looking to optimize their printing strategy.

Both printing methods have their unique advantages depending on the business’s needs. While DTF is usually favored for bulk orders and a broader range of fabric compatibility, DTG shines in providing intricate designs with a softer feel. Entrepreneurs should weigh these factors to make informed decisions about which printing method will best meet their business model and customer preferences. Exploring the DTF vs. DTG landscape offers valuable insights into how each technique can fulfill specific needs in the growing custom apparel market.

Fabric Compatibility in DTF vs. DTG

One of the critical aspects of custom apparel printing is fabric compatibility, particularly when evaluating DTF vs. DTG technologies. DTF printing is exceptionally versatile, successfully adhering to a wide range of materials, including cotton, polyester, and various blends. This adaptability makes DTF a go-to option for companies that deal with diverse fabrics or offer customization on multiple garment types. In contrast, DTG printing is predominantly suited for cotton or cotton-blend fabrics, limiting its application for businesses aiming to diversify their product lines with different material compositions.

The fabric compatibility of each method not only affects the options available to consumers but also impacts the overall quality and durability of the prints. DTG produces soft, detailed outputs on the cotton fabrics it favors but may struggle with longevity on lesser-treated materials. DTF, while it produces vibrant and crisp images on a more extensive range of textiles, may have a different feel post-application. Therefore, knowing the strengths and limitations of each printing method in relation to fabrics can help businesses align their products with customer expectations.

Durability and Maintenance Considerations for DTF and DTG Printing Methods

When exploring the realm of custom apparel printing, durability and maintenance emerge as pivotal factors, especially in the discussion of DTF vs. DTG. DTF printing is celebrated for its wash durability, with vibrant colors that can withstand repeated laundering while maintaining their boldness. This makes DTF particularly attractive for bulk orders where a lasting impression is desired. Conversely, DTG is known for its soft prints, showcasing fine details that resonate with quality-conscious consumers. However, the longevity of DTG prints can be more variable, often dependent on the fabric and care instructions followed by the end user.

Understanding the durability of each method allows businesses to set realistic expectations with customers while also educating them about proper garment care. For those who prioritize vibrant, long-lasting prints in their custom apparel offerings, DTF stands out as a reliable choice. On the other hand, brands that emphasize detail and a premium feel in their designs might gravitate towards DTG but will need to communicate clearly with consumers about maintaining the quality of the prints over time. In essence, aligning these insights with customer needs defines a successful custom printing strategy.

Pricing Strategies for DTF and DTG Printing

When it comes to navigating the cost of custom apparel printing, the pricing strategies associated with DTF and DTG printing can significantly influence business decisions. Generally, DTF is considered a more cost-effective method for small to medium runs due to its ability to mass-produce prints without sacrificing quality. This efficiency can be beneficial for businesses needing larger quantities for events or promotional materials. On the flip side, DTG may present higher individual piece costs due to the setup required for each print; however, it remains a solid option for custom, one-off pieces that demand high detail.

Understanding the cost structure is crucial for businesses when forecasting expenses and setting retail prices. Brands that specialize in custom designs might prefer the flexibility that DTG offers, despite potentially higher price points, as it allows for greater creative expression and a more personalized product offering. Meanwhile, those focusing on volume sales could benefit from DTF’s efficiency and reduced per-unit cost. Evaluating the pricing implications of each method helps businesses make informed choices about inventory, sales strategies, and customer engagement.

Technological Innovations in DTF and DTG Printing

The landscape of custom apparel printing is continuously evolving, with recent technological innovations significantly impacting DTF and DTG methods. Advances in print head technology and ink formulations have led to improvements in print quality and compatibility across various fabrics. Hybrid printers capable of executing both DTF and DTG tasks are emerging, offering businesses unprecedented versatility and streamlining production processes. Such developments provide an avenue for creators and entrepreneurs to explore new product ideas and expand their offerings.

Moreover, these innovations not only enhance the quality of prints but also improve production efficiency by reducing waste and operational limitations. With enhanced capabilities, businesses can cater to a broader audience, fulfilling unique requests while maintaining high standards. By staying ahead of technological trends in custom printing, businesses can position themselves competitively in the marketplace, ensuring they remain relevant in an increasingly dynamic industry.

Making the Right Choice: DTF vs. DTG for Your Business Needs

In summary, the decision between DTF and DTG printing methods is influenced by numerous factors tailored to specific business needs. DTF often appeals to companies looking for versatility in fabric compatibility and efficient production cycles, making it ideal for bulk orders across a variety of materials. Conversely, organizations that emphasize intricate, high-quality designs on cotton garments may find that DTG offers greater benefits, despite its limitations in material types and potential maintenance challenges.

To make the right choice, businesses should evaluate their target audience, product offerings, and desired outcomes. Questions surrounding the intended use of apparel, production timelines, and budget considerations can lead potential clients to the most suitable printing method. By thoroughly understanding the landscape of custom apparel printing—specifically the distinctions offered by DTF and DTG—businesses can enhance their service offerings, tailor their strategies to market demands, and foster customer loyalty.

Frequently Asked Questions

What is the main difference between DTF vs. DTG printing methods?

The primary difference between DTF (Direct-to-Film) and DTG (Direct-to-Garment) printing lies in their processes. DTF uses a film transfer method where designs are printed onto a film and then heat-transferred onto fabric, making it versatile for various materials. In contrast, DTG prints directly onto garments using inkjet technology, ideal for intricate designs but mainly suited for cotton and cotton blends.

Which is more cost-effective for short runs, DTF vs. DTG?

For short to medium runs, DTF (Direct-to-Film) printing is generally more cost-effective and offers faster production times compared to DTG (Direct-to-Garment). DTF’s ability to mass produce prints efficiently makes it a better choice for businesses needing quick turnaround without sacrificing quality.

How do fabric compatibilities differ in DTF vs. DTG printing?

DTF (Direct-to-Film) printing is more adaptable to various fabrics, including cotton, polyester, and blends, while DTG (Direct-to-Garment) printing mainly excels with cotton and cotton-blend fabrics. This fabric compatibility difference makes DTF a versatile option for custom apparel printing across diverse materials.

Which printing method produces higher quality prints, DTF vs. DTG?

DTG (Direct-to-Garment) printing typically produces higher quality prints, especially for detailed and colorful designs, offering a soft feel on garments. However, DTF (Direct-to-Film) printing also provides vibrant colors with excellent wash durability, making it suitable for bulk orders.

How do environmental impacts compare in DTF vs. DTG printing?

In terms of environmental impact, DTF (Direct-to-Film) printing tends to be more sustainable due to its lower ink consumption. While both DTF and DTG (Direct-to-Garment) increasingly use water-based inks and eco-friendly practices, DTF’s efficiency makes it a better choice for environmentally conscious printing.

When should I choose DTF vs. DTG for my custom apparel needs?

Choose DTF (Direct-to-Film) if you need versatility across fabric types and faster production for larger orders. Opt for DTG (Direct-to-Garment) if your focus is on high-quality, detailed prints primarily for cotton materials. Your choice should align with your specific business needs and printing volume.

| Key Points | Direct-to-Film (DTF) | Direct-to-Garment (DTG) |

|---|---|---|

| Printing Process | Prints designs on film, transfers to fabric using heat. | Uses inkjet technology to print directly onto fabrics, requires pre-treatment. |

| Fabric Compatibility | Compatible with various materials (cotton, polyester, blends). | Mainly suited for cotton and cotton-blend fabrics. |

| Quality and Durability | Vibrant colors with good wash durability, slightly less soft feel. | Exceptionally soft prints, rich details, potentially shorter longevity. |

| Cost and Production Speed | Cost-effective for bulk orders, faster production for medium runs. | Slower production for high volumes, better for custom one-off designs. |

| Environmental Considerations | Lower ink consumption contributes to sustainability. | Utilizes water-based inks but higher ink consumption. |

Summary

DTF vs. DTG printing methods present distinct features suited for various applications in the custom apparel industry. DTF focuses on versatility and vibrancy, adapting superbly to different fabrics with a process that involves film transfer. Conversely, DTG shines in providing high-quality, intricate designs directly onto garments but is limited in fabric compatibility. The two methods cater to different needs—from bulk production to detailed customization—making it essential to choose based on specific business requirements and target audience preferences. Understanding these differences enables apparel businesses to select the optimal printing method that aligns with their operational goals.