DTF vs DTG is a pivotal decision for brands designing apparel, and choosing wisely can influence color fidelity, edge sharpness, texture, wash durability, and overall production costs across multiple product lines, from tees to outerwear. As you weigh options, consider color vibrancy across light and dark fabrics, the breadth of fabric compatibility with each method (cotton, blends, and some synthetics), as well as the finish quality, soft hand feel, and required post-processing steps. This guide compares DTF printing and DTG printing, explains the underlying mechanics—such as film-based transfer versus direct fabric deposition—and outlines practical trade-offs that affect scalability, consistency, setup cost, and long-term maintenance. For t-shirt printing projects, the choice can influence how colors render on dark backgrounds, the perceived texture of the ink, and the reliability of adhesion across different garment types while keeping an eye on production speed and waste. In the end, you’ll gain a clearer sense of when one approach delivers the best balance of color, detail, hand feel, and cost for your specific designs and business goals.

Seen through an alternative lens, this topic resembles a comparison between film-based transfers and direct-to-fabric deposition, inviting readers to weigh methods by substrates, durability, and overall impact on margins. The film-based path relies on an intermediate transfer film and adhesive, while the direct-to-fabric path deposits ink directly into fibers and often requires pre-treatment and curing to maximize washfastness. For brands evaluating options, the key signals are substrate versatility, color stability over washes, and how the production workflow scales across styles and sizes. This broader framing helps align decision-making with catalog breadth, sustainability goals, and the realities of factory throughput, rather than chasing sample-perfect results alone. By testing small proofs across fabrics and tracking hand feel, image sharpness, and durability, you can map your designs to the most compatible method with confidence.

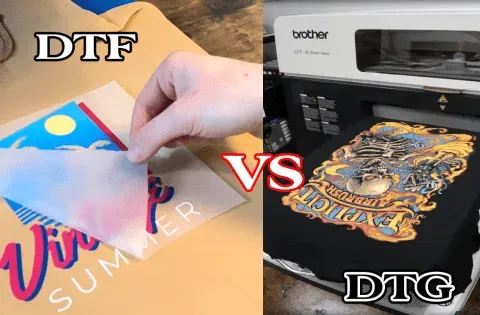

DTF vs DTG: A Clear Print Method Comparison for Apparel

DTF vs DTG is a core decision for anyone involved in print method comparison, especially when planning t-shirt printing with diverse fabric options. DTF printing relies on a PET film, CMYK inks, and a white underbase, followed by an adhesive transfer to the garment. DTG printing, by contrast, deposits inks directly onto the fabric using water-based inks and usually requires pre-treatment for darker fabrics. Understanding these distinct workflows helps designers weigh color vibrancy, hand feel, and durability across substrates.

In practice, this comparison highlights how each method shines under different conditions. DTF offers versatility across cotton, blends, and some synthetics, with strong color reproduction and lower setup costs for mid-volume runs. DTG excels in high-detail imagery and soft hand feel on compatible fabrics like 100% cotton, though it can incur higher upfront printer costs and sensitivity to fabric choice and pretreatment quality. This framing sets the stage for practical decisions in print method comparison and fabric compatibility.

DTF Printing: Versatility and Color Fidelity Across Fabrics

DTF printing stands out for its ability to deliver vibrant colors on a wide range of fabrics. Because the white underbase is created on the film, DTF can preserve brightness on both dark and light materials without extensive pre-treatment. This makes DTF a strong option for diverse t-shirt printing projects that include blends, satins, and even some synthetics, where fabric compatibility might otherwise complicate color fidelity.

Beyond fabric flexibility, DTF typically offers favorable setup economics for mid- to high-volume runs. The adhesive-backed films and curing steps enable scalable production while maintaining consistent print quality. When considering print method comparison, DTF’s strength lies in reliable color density and durability across substrates, making it a practical choice for brands seeking broad product portfolios.

DTG Printing: High-Detail Graphics and Soft Hand Feel on Cotton

DTG printing specializes in high-detail, full-color graphics with smooth gradients, particularly on 100% cotton or high-cotton blends. The direct deposition of ink onto the fabric contributes to a naturally soft hand feel, which many designers and customers associate with premium t-shirt printing. A well-executed DTG workflow relies on careful pre-treatment for dark fabrics to maximize color vibrancy and adhesion.

While DTG delivers exceptional image quality, it often requires a higher initial investment in equipment and ongoing maintenance. Performance can be sensitive to fabric type, ink chemistry, and pretreatment quality, making DTG a strong fit for detailed designs on cotton but possibly less cost-effective for broad fabric variety or very high-volume runs.

Fabric Compatibility and Pre-Treatment: Aligning Your Design with the Right Method

Fabric compatibility guides the choice between DTF and DTG. DTG tends to shine on natural fibers like 100% cotton, where ink sits within the fiber for a soft finish, but it relies on uniform pre-treatment to ensure color vibrancy on darker fabrics. DTF, with its film transfer and adhesive, offers broader fabric compatibility, including blends and some synthetics, with less dependence on fabric-specific pretreatment.

Pre-treatment quality and consistency remain critical for DTG, where uneven coverage can create color inconsistencies or washfastness issues. DTF reduces some pretreatment concerns since the white underbase is handled during the film stage, but achieving reliable adhesion and curing on various fabrics still requires careful process control and testing across materials to ensure durable, color-accurate results.

Cost, Speed, and Production Workflow: Choosing Between DTF and DTG

When evaluating cost, speed, and production workflow, DTG often presents higher upfront and maintenance costs due to specialized printers and pretreatment systems. However, for small runs with intricate color, DTG can deliver fast turnarounds for single garments or small batches that demand high-detail t-shirt printing. DTF, by contrast, tends to offer lower per-unit costs for larger runs, especially when a consistent design runs across multiple fabrics.

From a production perspective, DTF workflows—printing to film, curing, and transferring—can be highly scalable, particularly for larger catalogs. DTG shines in rapid prototyping and short runs with complex color, provided the fabric mix remains favorable and pretreatment is well-managed. Consider your brand’s volume, fabric variety, and energy use when weighing environmental considerations and overall efficiency.

Practical Guidelines for Designers: Best Practices for DTG and DTF Projects

To maximize results, design with the chosen method in mind. For DTG, craft artwork with high-resolution details and smooth color transitions, anticipating the impact of pretreatment on dark fabrics. For DTF, plan color separations with the white underbase produced on film, and test how the adhesive transfer adheres to each fabric variant in your collection.

Practical testing is essential: run proofs, evaluate hand feel, color density, and wash durability across fabrics. Calibrate color profiles, use ICC targets, and validate performance with real-world wear. By aligning your artwork, fabric choices, and production workflow through an iterative testing process, you can optimize t-shirt printing outcomes while balancing cost, speed, and quality.

Frequently Asked Questions

DTF vs DTG: Which printing method offers better fabric compatibility across a range of materials?

DTF printing generally delivers strong fabric compatibility because the film-based transfer with a white underbase can be applied to cotton, blends, and some synthetics. DTG printing works best on 100% cotton or high-cotton blends with appropriate pre-treatment. If you need flexibility across multiple fabrics, DTF vs DTG tips the scale toward DTF for versatile fabric compatibility.

DTF vs DTG: How do color vibrancy and hand feel compare between DTF printing and DTG printing?

DTG printing on light cotton offers exceptionally detailed color with a soft hand feel. DTF printing delivers vivid colors across a wider range of fabrics, though some fabrics may feel slightly firmer after transfer if not finished properly. Both can achieve durable results with proper curing and finishing.

DTF vs DTG: Which is more cost-effective for small runs or large-volume production?

DTG typically requires a higher upfront investment and ongoing maintenance, which can raise per-unit costs for small runs. DTF tends to offer lower per-unit costs for larger runs and can scale well in batch production with a film-transfer workflow, making it often more cost-effective at higher volumes.

DTF vs DTG: Which method is best for t-shirt printing with a mix of fabrics?

DTF printing is often more versatile for a mix of fabrics, including blends and non-cotton options. DTG excels on 100% cotton tees with detailed graphics, so for a mixed-fabric t-shirt printing approach, many brands use DTF for non-cotton items and DTG for cotton-heavy designs.

DTF vs DTG: What are the main differences in durability and washfastness?

Both methods can be durable when properly cured and finished. DTG durability depends on ink chemistry, pretreatment quality, and proper washing care, while DTF durability hinges on film transfer adhesion and curing. Following recommended heat-press times, temperatures, and wash guidelines is key for longevity in either method.

DTF vs DTG: What practical tips help optimize outcomes for high-detail designs?

For high-detail designs, plan around the chosen method: use high-resolution artwork and soft color transitions for DTG, and ensure color separations account for the white underbase on film for DTF. Optimize fabric testing, pretreatment quality for DTG, and film transfer techniques plus curing for DTF. Run small proofs to compare hand feel, color density, and durability before full production.

| Topic | DTF | DTG | Key Takeaway |

|---|---|---|---|

| What is DTF printing? | Direct-to-Film; design printed on a PET film with CMYK inks, usually with a white underbase; the film is then heat-pressed onto the garment with adhesive. | Direct-to-Garment; ink is printed directly onto fabric with water-based inks; pretreatment is often required for dark fabrics. | DTF uses film-based transfers and offers fabric versatility; DTG prints directly on fabric for high-detail cotton but typically requires pretreatment on darks. |

| What is DTG printing? | DTF stands for Direct-to-Film; prints onto a PET film with CMYK inks (often with white underbase) before transfer. | DTG stands for Direct-to-Garment; prints directly on fabric using textile printers with water-based inks and typically requires pretreatment for dark fabrics. | DTG excels at direct fabric printing with high detail on cotton; DTF is more versatile across fabrics. |

| Fabric compatibility and white underbase | White underbase is created on the film; flexible across many fabrics; dark fabrics supported without garment-wide pretreatment. | Printed directly on the fabric; often requires pretreatment for dark fabrics; performance varies by fabric. | DTF offers broader fabric versatility; DTG relies on pretreatment and fabric choice. |

| Color vibrancy and detail | Vivid colors and good detail across fabrics; hand may feel stiffer on some materials. | Highly detailed color with smooth gradients; usually a softer hand on cotton. | DTG provides the softest hand and finest detail on cotton; DTF is versatile across substrates. |

| Durability and washfastness | Durable with proper curing; strong wash durability across fabrics. | Durable with proper pretreatment and curing; results vary by fabric. | Both can be durable with correct processing; results depend on curing and post-processing. |

| Setup, cost, and production speed | Lower per-unit cost for mid- to high-volume runs; modular workflow; batch-friendly. | Higher upfront investment and ongoing maintenance; optimized for fast single garments but higher cost per unit. | DTF scales well for volume; DTG suits high-detail on cotton but with higher ongoing costs. |

| Labor and workflow | More flexible for a broad product catalog; involves film handling and transfer steps. | Great for fast, small runs with complex color; sensitive to fabric type and pretreatment quality. | DTF supports batch production; DTG excels at rapid, detail-driven small runs. |

| Hand feel and finish | Transfers can feel slightly stiffer; improvements with newer formulations. | Typically softer hand on compatible fabrics; ink sits closer to fibers. | DTG often yields a softer hand; DTF results vary by film/adhesive, though finishing has improved. |

| Practical tips | Optimize designs for film transfer; account for white underbase and curing steps. | Design with high-resolution artwork; test pretreatment, fabric types, and color management. | Run proofs and test on target fabrics to compare hand feel, color density, and durability. |

| Common myths and misconceptions | Not only for low-quality prints; DTF improvements have expanded color fidelity and durability. | DTG is always the best for photo-quality on every fabric; not true—depends on fabric and workflow. | DTG is slower and more expensive in all cases; depends on order size, fabric mix, and processing. |

Summary

DTF vs DTG is not a one-size-fits-all decision. Both printing methods have distinct strengths, and the right choice hinges on your designs, fabrics, production volumes, and business goals. If you prioritize versatility and cost-effective production across a wide fabric range, DTF printing is a strong option. If you value ultra-fine detail, a soft hand feel on cotton, and a high-end look for color-rich graphics, DTG printing remains an excellent choice. Many brands adopt a hybrid approach, using DTG for certain collections and DTF for others to optimize quality, speed, and cost. By understanding how DTF printing and DTG printing work, evaluating your fabric choices, and aligning your workflow with your design ambitions, you can make an informed decision that supports your brand’s growth. Whether you choose DTF vs DTG for your designs, the goal is to deliver vibrant, durable graphics that delight customers while maintaining efficient operations for your apparel business.