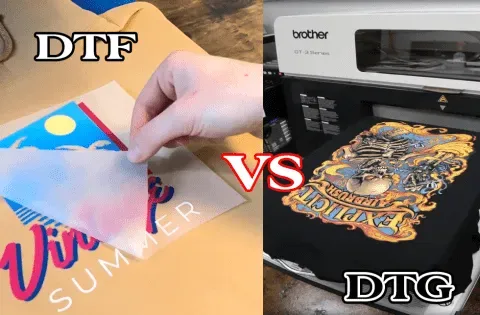

When exploring the world of textile printing, a common dilemma arises: **DTF vs. DTG**. These two printing techniques—Direct to Film (DTF) and Direct to Garment (DTG)—each offer unique advantages, catering to different needs within the industry. DTF printing is becoming increasingly favored due to its versatility across various fabrics, while DTG printing shines with its capacity for detailed designs and high-resolution outputs. Understanding the nuances between DTF and DTG can help businesses identify the best printing methods for their specific applications. In this post, we’ll break down these textile printing techniques, equipping you with the essential insights needed to choose between these final printing options for your projects.

In the realm of textile decoration, two formidable contenders emerge when discussing printing methods: **Direct to Film** and **Direct to Garment**. Additionally known as DTF and DTG, these printing processes cater to a wide spectrum of artistic and commercial needs. While DTG printing often excels in delivering intricate artwork directly onto fabric, DTF printing stands out in its compatibility with various materials, offering a durable and flexible solution. As businesses evaluate their options among textile printing techniques, understanding the comparative benefits of DTF and DTG becomes crucial for making informed decisions that align with their production goals. This analysis aims to shed light on the best approaches for modern printing requirements.

Understanding DTF Printing Basics

Direct to Film (DTF) printing has revolutionized the way designs are transferred onto textiles, offering a unique method that provides incredible versatility. Unlike traditional textile printing techniques, DTF involves printing designs on a special film which is later heat-pressed onto various fabrics. This allows businesses to cater to a wider array of materials beyond just cotton, including polyester and blends. The result is vibrant and intricate designs that maintain their quality, making DTF a standout method for modern printing needs.

Moreover, the process of DTF printing is straightforward and efficient. After printing the design onto the transfer film, a layer of adhesive is applied before the design is heat pressed onto the fabric. This method not only enhances durability but also ensures that the applied graphics withstand frequent washing without fading. As such, DTF has become an increasingly popular choice in the industry for apparel that requires frequent use, like sportswear and work apparel.

Examining DTG’s Unique Features

Direct to Garment (DTG) printing utilizes specialized inkjet technology to ink the fabric directly, allowing for incredibly detailed and colorful designs. Designers often favor this method for its ability to handle complex images that require fine details and a variety of colors. While DTG is ideal for custom jobs and low runs, particularly on 100% cotton garments, it does have specific material requirements that can limit its application in broader textile printing.

Despite its high-quality output, DTG printing can be significantly slower compared to other methods like DTF, making it less favorable for large production orders. Furthermore, the necessity of pre-treatment for fabric can complicate the process, prolonging production time and increasing costs. Businesses looking for flexibility in their printing methods must weigh these factors when considering DTG as their primary printing option.

Key Differences: DFF vs. DTG

When evaluating the differences between DTF and DTG printing, one must consider several factors, including the process, quality, and durability of each technique. DTF printing excels in its ability to apply vibrant graphics onto various fabrics by avoiding the limitations found in DTG’s dependency on high-quality cotton. Additionally, DTF prints tend to have a longer lifespan, maintaining their appearance after numerous washes without extensive color loss.

In contrast, DTG’s strength lies in producing high-resolution details that are hard to replicate with other methods. It is the preferred choice for businesses focused on creating custom, detailed apparel, especially when the order quantities are small. However, the trade-off for this quality is the necessity for high-quality materials and longer production times, which is less efficient for bulk printing orders.

Durability of DTF vs. DTG Prints

Durability is a critical consideration in textile printing, particularly in industries like fashion and sportswear where garments are subject to heavy use. DTF printing is often recognized for its superior resilience; the prints hold up exceptionally well against repeated washes and wear, making them ideal for items such as uniforms or activewear. The unique adhesive and film combination ensures that designs remain vibrant and intact, even under difficult conditions.

On the other hand, while DTG produces stunningly detailed prints, they can face challenges regarding durability compared to DTF alternatives. Prints from DTG technology may begin to fade or show wear much sooner, especially if not properly maintained. This can impact customer satisfaction and repeat business, demanding that businesses carefully consider their material choices and production methods when deciding on their printing strategy.

Cost Considerations for DTF and DTG

The costs associated with DTF and DTG printing can significantly influence a business’s decision on which method to adopt. DTG printers generally come with a higher initial investment, along with ongoing maintenance costs that can burden small businesses. These overheads can deter new entrants in the market looking for cost-effective solutions, especially when exploring custom printing options.

In comparison, DTF printing setups typically require a lower initial investment and fewer ongoing costs, making it appealing for companies that prioritize budget efficiency. This financial advantage can be particularly beneficial in larger production settings where rapid turnaround times and cost management are crucial. Balancing quality with affordability is essential for businesses looking to optimize their printing practices.

Choosing Between DTF and DTG for Your Business

Determining whether DTF or DTG is the right option for your printing needs depends significantly on your specific business objectives, target audience, and the nature of the garments you produce. If detailed, high-quality designs on cotton garments are what you primarily offer, then DTG can be the best choice for you. Its ability to create beautiful, intricate custom pieces is unmatched in that regard.

Conversely, if your business demands versatility, speed, and durability across multiple fabric types, opting for DTF will likely serve you better. This method allows for flexibility in production while ensuring you can meet market demands promptly. Ultimately, understanding your audience’s preferences and the specifics of your garment production will guide you in making the most effective choice between these two printing techniques.

Frequently Asked Questions

What are the main differences between DTF printing and DTG printing?

The key differences between DTF printing and DTG printing include the printing process, fabric compatibility, durability, and cost. DTF uses a film transfer method that works on various materials, while DTG prints directly onto garments, primarily 100% cotton. DTF prints tend to be more durable and cost-effective for larger productions, whereas DTG excels in delivering high-detail designs for smaller custom runs.

Is DTF printing better than DTG printing for durability?

Yes, DTF printing is generally considered better than DTG printing for durability. DTF prints demonstrate superior wash resistance and maintain vibrant colors even after multiple washes, making them ideal for items that will undergo heavy use, such as workwear or sports apparel.

Which is more cost-effective: DTF printing or DTG printing?

DTF printing is usually more cost-effective than DTG printing. The initial setup costs for DTG printers can be high, along with ongoing maintenance expenses. In contrast, DTF printing setups typically have lower operational costs, making them attractive for businesses seeking to balance quality with budget constraints.

Can DTF printing be used on different fabric types compared to DTG printing?

Yes, DTF printing can be used on a wider variety of fabric types than DTG printing. While DTG printing works best on 100% cotton, DTF printing is versatile and can be applied to cotton, polyester blends, and even nylon, increasing its usability across different textile materials.

What type of printing is better for detailed designs: DTF printing or DTG printing?

For detailed designs, DTG printing is often the better choice. It employs inkjet technology to produce intricate, high-resolution graphics directly on garments, making it ideal for custom apparel with complex designs. However, DTF technology is also catching up in quality and flexibility.

Which printing method is faster for bulk orders, DTF or DTG?

DTF printing is generally faster for bulk orders compared to DTG printing. DTF allows for quicker production times, making it advantageous for businesses that require faster turnaround for larger quantities, whereas DTG can be slower, especially for custom jobs.

| Key Points | DTG (Direct to Garment) | DTF (Direct to Film) |

|---|---|---|

| Printing Process | Uses inkjet technology to print directly onto garments. | Prints designs onto a special film that is then heat-pressed onto the fabric. |

| Material Compatibility | Best on 100% cotton fabrics; limited options for other materials. | Versatile; works on cotton, polyester blends, and even nylon. |

| Durability | Can fade and wear over time with frequent washing. | Superior durability; maintains quality through multiple washes. |

| Cost and Setup | Higher initial and maintenance costs; ideal for custom orders. | Lower operational costs and maintenance; good for bulk orders. |

| Production Speed | Slower; better for small batches and custom jobs. | Faster; ideal for bulk orders due to quick production times. |

Summary

DTF vs. DTG is a critical consideration for any business involved in textile printing. Direct to Garment (DTG) printing offers unmatched detail and quality for custom designs on cotton, making it a preferred option for personalized apparel. However, Direct to Film (DTF) printing shines with its versatility, durability, and faster production speeds suitable for a variety of materials. Ultimately, the choice between DTF and DTG should align with your production needs, target market, and product usage, allowing you to effectively meet customer demands and enhance your brand’s offerings.