UV DTF, or UV Direct to Film printing, is revolutionizing the custom printing landscape by offering a robust solution for creating detailed and vibrant prints on a variety of surfaces. This cutting-edge print technology brilliantly merges the advantages of UV printing with the versatility of Direct to Film methods, delivering eye-catching and durable results that stand the test of time. As businesses increasingly seek sustainable printing options, UV DTF stands out for its eco-friendly capabilities and efficiency, reducing waste and ink consumption compared to traditional printing processes. In this exploration, we will uncover the numerous benefits of UV DTF and why it’s being hailed as the future of custom printing. From textiles to hard surfaces, UV DTF is poised to transform how brands communicate their identity through visually stunning merchandise.

The world of custom printing is continually evolving, and the integration of innovative technologies like UV Direct to Film printing is at the forefront of this transformation. Often referred to simply as UV DTF printing, this modern technique represents a synthesis of UV printing methods and the adaptability of transfer film technology. It not only produces high-quality images with impressive color vibrancy but also caters to a wide array of materials, making it an indispensable tool for businesses in need of personalized solutions. This article will provide insights into the various benefits associated with this print technology, conveniently illustrating its advantages over conventional methods while highlighting its role in fostering sustainable printing practices.

Exploring the Versatility of UV DTF Printing

UV DTF printing technology is revolutionizing the industry by introducing remarkable versatility in applications. One of the hallmark features of this process is its ability to adapt to a variety of substrates, including textiles, plastics, metals, and even wood. This adaptability allows businesses to cater to a wide demographic, offering customized solutions that meet individual preferences and needs. Whether it’s creating personalized fashion items like t-shirts and bags or producing unique promotional merchandise, UV DTF’s extensive range makes it an invaluable tool for modern printing businesses.

Moreover, the versatility is not just limited to the choice of materials. UV DTF printing also excels in different scales of production. Businesses can efficiently handle both small batches for niche markets and larger orders for mass distribution, thus enhancing their operational flexibility. This adaptability not only increases customer satisfaction by providing tailored products but also opens new avenues for creativity in design and production.

High-Quality Prints with UV DTF Technology

The quality of prints produced by UV DTF technology is unparalleled, characterized by vibrant colors, sharp details, and significant durability. Unlike traditional printing methods, UV DTF utilizes ultraviolet light to cure ink instantly on the transfer film, resulting in a finish that is exceedingly bright and resistant to environmental damages. The vibrancy of colors remains intact even after prolonged exposure to sunlight, making it ideal for products intended for outdoor use, such as signage or promotional items.

Beyond just colors, the definition and clarity achieved through UV DTF printing allow for intricate designs, enabling businesses to offer high-quality custom printing for detailed artworks. The durability offered by UV-cured inks also means that prints are scratch-resistant and can withstand water damage, which is essential for products that are frequently handled. Therefore, UV DTF not only meets aesthetic demands but also aligns with practical needs for longevity and resilience.

Sustainable Practices in UV DTF Printing

As consumers become increasingly aware of environmental issues, the focus on sustainable printing technologies has intensified. UV DTF printing is emerging as a leading option in this regard due to its eco-friendly characteristics. The process typically utilizes less ink compared to traditional methods, which reduces waste and promotes energy efficiency. Additionally, many UV DTF inks are formulated to be less harmful, aligning with the growing consumer demand for environmentally responsible products.

Furthermore, the efficiency of the UV DTF printing process minimizes overall waste, making it an attractive choice for businesses aimed at adopting sustainable practices. Companies can produce high-quality prints while also showcasing their commitment to environmental stewardship. By choosing UV DTF, businesses not only enhance their product offerings but also contribute positively to the global push for sustainability in the printing industry.

Cost Efficiency of UV DTF Printing

When it comes to running a business, cost is always a key consideration, and UV DTF printing excels in this area. One of the significant advantages of this technology is the reduction in setup and production times. Unlike traditional printing methods, which may require lengthy setup processes, UV DTF streamlines production, enabling quicker turnaround times on projects. As a result, businesses can respond swiftly to customer demands, maintaining a competitive edge in the market.

Additionally, UV DTF printing proves to be financially feasible for both short and long production runs. Many conventional printing solutions involve high setup costs that make small orders impractical, but UV DTF allows companies to offer customized products without the burden of excessive expenditures. This flexibility in pricing and production ensures that businesses of any size can compete in the custom printing arena without sacrificing quality or speed.

Recent Innovations in UV DTF Technology

The UV DTF printing landscape is continuously evolving, driven by technological advancements that enhance efficiency and quality. Recent innovations have introduced faster print speeds, allowing businesses to increase production capacity without sacrificing print quality. These improvements streamline the overall workflow, making it easier for companies to meet growing market demands for customized products.

Alongside improvements in print speeds, advancements in ink formulations have led to bright and long-lasting prints. The introduction of new, high-performance inks means businesses can expect even better vibrancy and durability from their prints. Additionally, modern equipment designed for UV DTF printing offers greater precision, further enhancing the quality of the outputs. As these developments unfold, UV DTF technology is poised for explosive growth and adoption across various industries.

Adoption of UV DTF Technology by Renowned Brands

The adoption of UV DTF printing technology by leading brands signals a significant shift in the custom printing landscape. As major companies recognize the advantages of this method, including its adaptability, efficiency, and sustainable practices, they are integrating UV DTF into their production lines. This shift not only highlights the technology’s efficacy but also sets a precedent for other businesses to explore its capabilities, fostering a broader acceptance in the market.

Notably, industries such as fashion and merchandise are embracing UV DTF for custom branding solutions. This integration demonstrates how UV DTF can provide brands with the high-quality results they require while supporting sustainable initiatives. The success and recognition of UV DTF by influential brands serve to validate its potential as a preferred choice for modern printing needs, paving the way for broader adoption in various sectors.

Frequently Asked Questions

What is UV DTF printing and how does it differ from traditional UV printing?

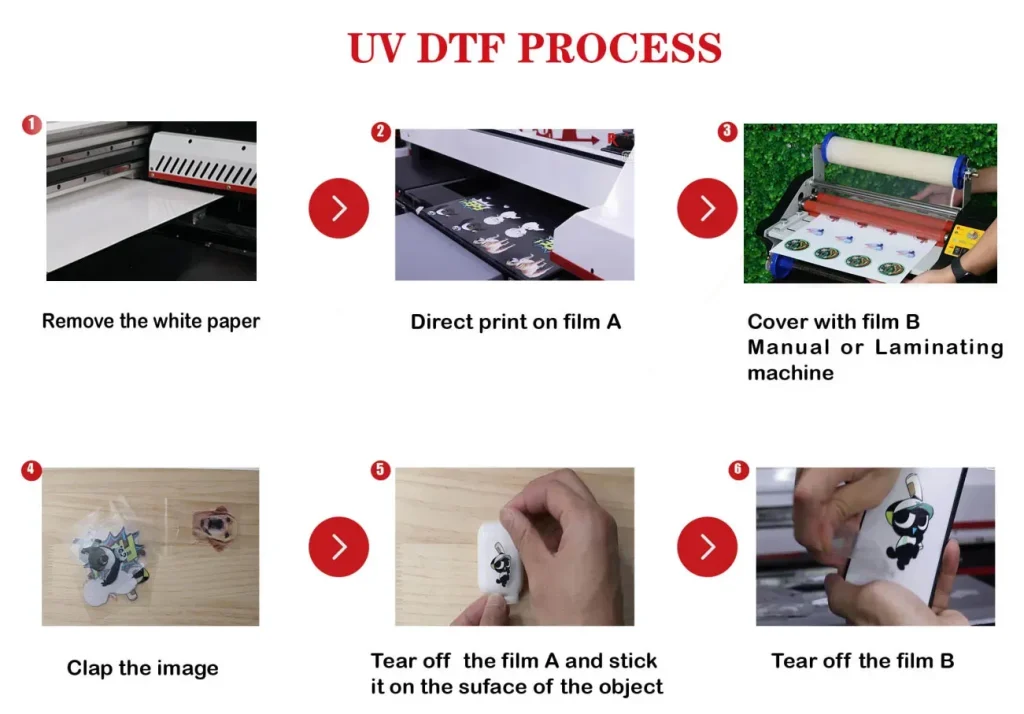

UV DTF (Direct to Film) printing is an innovative method that combines UV printing technology with transfer film techniques to produce high-quality, vibrant prints on various surfaces. Unlike traditional UV printing that directly applies ink to substrates, UV DTF first prints onto a special film which is then transferred to the desired material, offering greater versatility and adaptability for custom printing.

Can UV DTF printing be used on different materials?

Yes, UV DTF printing is extremely versatile and can be used on a wide range of materials including textiles (like T-shirts and bags), plastics (such as water bottles), metals, glass, and wood. This adaptability is one of the key reasons why UV DTF is gaining popularity in the custom printing industry.

How does UV DTF technology contribute to sustainable printing practices?

UV DTF technology supports sustainable printing by using eco-friendly inks and minimizing waste. It consumes less ink than traditional methods and the efficient process generally produces fewer by-products, making it a greener choice for businesses concerned with environmental impact.

What are the advantages of UV DTF over traditional DTF printing?

UV DTF offers several advantages over traditional DTF printing, including faster curing times due to UV light, producing more vibrant and durable prints, and the ability to print on a wider variety of substrates. This makes UV DTF a preferred option for businesses seeking high-quality, custom solutions.

Is UV DTF printing cost-effective for small production runs?

Yes, UV DTF printing is cost-effective, particularly for small production runs. Its streamlined setup process and reduced production times lower costs significantly compared to traditional methods, enabling businesses to offer customized products without high setup expenses.

What trends are emerging in UV DTF printing technology?

Recent trends in UV DTF printing technology include advancements in print speeds, improved ink formulations resulting in brighter prints, and the adoption of the technology by major brands for enhanced custom branding solutions. These developments indicate a growing market and increasing acceptance of UV DTF as a leading choice in custom print technologies.

| Key Points | Details |

|---|---|

| Versatility in Materials | Can print on textiles, plastics, metals, glass, wood, and more. |

| Vibrant and Durable Prints | Produces bright colors, sharp details, and is resistant to damage. |

| Eco-Friendly Options | Uses less ink, eco-friendly formulations, and minimizes waste. |

| Cost Efficiency | Faster production times and lower costs for small runs. |

| Technological Advancements | Includes improved print speeds, quality, and advanced equipment. |

| Market Growth | Increasing demand for customized products drives interest. |

| Adoption by Major Brands | Major companies incorporate UV DTF for branding solutions. |

Summary

UV DTF printing technology is revolutionizing the custom printing sector by offering remarkable versatility, durability, and sustainability. As a process that integrates cutting-edge innovations with eco-friendly practices, UV DTF meets the increasing demands of businesses and consumers seeking high-quality custom solutions. With its ability to print on a variety of substrates while ensuring vibrant, long-lasting results, UV DTF is set to become the leading choice in the printing industry, enabling brands to stay ahead in a competitive market while addressing environmental responsibilities.